Affinity vinyl cyanide base co-polymer superfine fibre film preparation method and application

An ultra-fine fiber, acrylonitrile-based technology is applied in the field of preparation of an affinity acrylonitrile-based copolymer ultra-fine fiber membrane, and achieves the effects of simple preparation, simple and feasible immobilization method, and improved immobilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

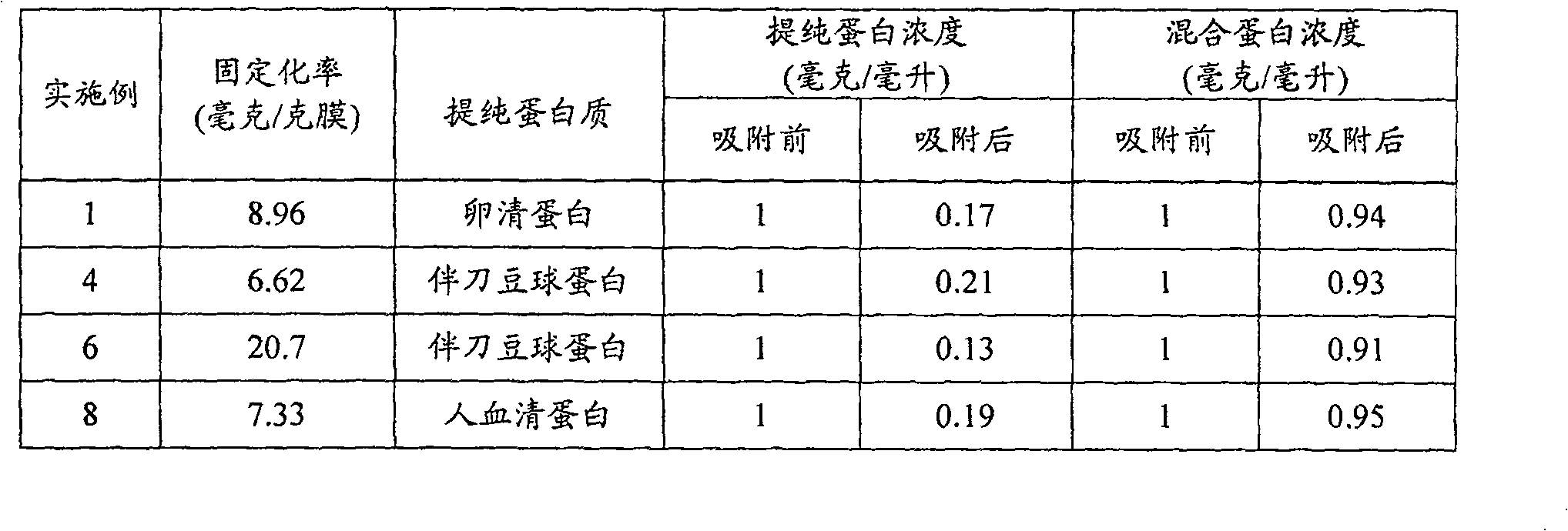

Examples

Embodiment 1

[0023] The acrylonitrile / allylamine copolymer (viscosity-average molecular weight is 80,000) that mass fraction is 4% is dissolved in the dimethylacetamide solvent (being the mass percent of acrylonitrile / allylamine copolymer in dimethylacetamide Concentration is 4%), under the condition that the spinning voltage is 20 kilovolts, the spinneret solution flow rate is 0.5 ml / hour, and the receiving distance is 15 centimeters, electrospinning is carried out to prepare acrylonitrile with a diameter of 98 ± 14 nanometers Base copolymer microfiber membrane.

[0024] Dissolve chitosan with a viscosity-average molecular weight of 7000 in an acetic acid-sodium acetate buffer solution of pH 5.0, stir at room temperature for 24 hours, and prepare a homogeneous transparent solution with a mass fraction of 5 mg / ml; at 25°C, add 0.1 10 milliliters of acrylonitrile-based copolymer microfiber membranes were immersed in 10 milliliters of pH in 6.0 volume fractions of 1% glutaraldehyde aqueous s...

Embodiment 2

[0026] The acrylonitrile / allylamine copolymer (viscosity-average molecular weight is 80,000) that mass fraction is 4% is dissolved in the dimethyl sulfoxide solvent, is 20 kilovolts at spinning voltage, spinneret solution flow rate is 0.5 ml / Electrospinning is carried out under the conditions of 1 hour and a receiving distance of 15 cm, and an acrylonitrile-based copolymer ultrafine fiber membrane with a diameter of 98 ± 14 nm is prepared.

[0027] Dissolve chitosan with a viscosity-average molecular weight of 7000 in acetic acid-sodium acetate buffer solution of pH 5.0, stir at room temperature for 24 hours, and form a homogeneous transparent solution with a mass fraction of 10 mg / ml; 0.1 gram of acrylonitrile-based copolymer microfiber membrane is immersed in 10 milliliters of pH and is 6.0 in the glutaraldehyde aqueous solution of 5% by volume fraction, activates 12 hours, and the fiber membrane after the activation uses a large amount of buffer solution (buffer with dissol...

Embodiment 3

[0029] The acrylonitrile / methallylamine copolymer (viscosity-average molecular weight is 240,000) that mass fraction is 5% is dissolved in dimethylformamide solvent, is 12 kilovolts at spinning voltage, spinneret solution flow rate is Electrospinning was carried out under the conditions of 1.0 ml / hour and a receiving distance of 15 cm to prepare an acrylonitrile-based copolymer ultrafine fiber membrane with a diameter of 190±20 nm.

[0030]Dissolve chitosan with a viscosity-average molecular weight of 7000 in an acetic acid-sodium acetate buffer solution of pH 5.0, stir at room temperature for 24 hours, and prepare a homogeneous transparent solution with a mass fraction of 5 mg / ml; at 25°C, add 0.1 10 milliliters of acrylonitrile-based copolymer microfiber membranes were immersed in 10 milliliters of pH in 6.0 volume fractions of 1% glutaraldehyde aqueous solution, and activated for 12 hours. Consistent) rinse, filter dry, then put into chitosan solution and react for 10 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com