Preparation method of wool immobilized enzyme and wool immobilized enzyme column reactor

A technology of immobilized enzymes and reactors, which is applied to specific-purpose bioreactors/fermenters, biochemical equipment and methods, enzyme production/bioreactors, etc., and can solve the problem of poor stability and low reusability of immobilized enzymes and other problems, to achieve the effect of pH stability and repeated use stability enhancement, excellent mass transfer performance and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of crude enzyme solution:

[0053] Construction of recombinant expression strain capable of expressing amino acid dehydrogenase with His-tag tag: the gene sequence of amino acid dehydrogenase (AaDH) is shown in SEQ ID NO.1. After the PCR amplification product was identified by 1% agarose gel electrophoresis, the AaDH gene fragment was recovered from the gel, and NdeI and XhoI enzymes were used to carry out double digestion, and the digestion product was recovered, and the same double digestion pET-28a plasmid (with with His-tag tag) for ligation, and the ligated plasmid was transformed into Escherichia coli BL21 (DE3) to obtain the pET28a-AaDH plasmid. The above plasmid was transformed into E.coli BL21(DE3) to obtain a recombinant expression strain E.coli BL21(DE3) / pET28a capable of expressing amino acid dehydrogenase with His-tag tag.

[0054]Cultivation of recombinant Escherichia coli E. coli BL21(DE3) / pET28a: Inoculate the strain into 200 mL of LB me...

Embodiment 2

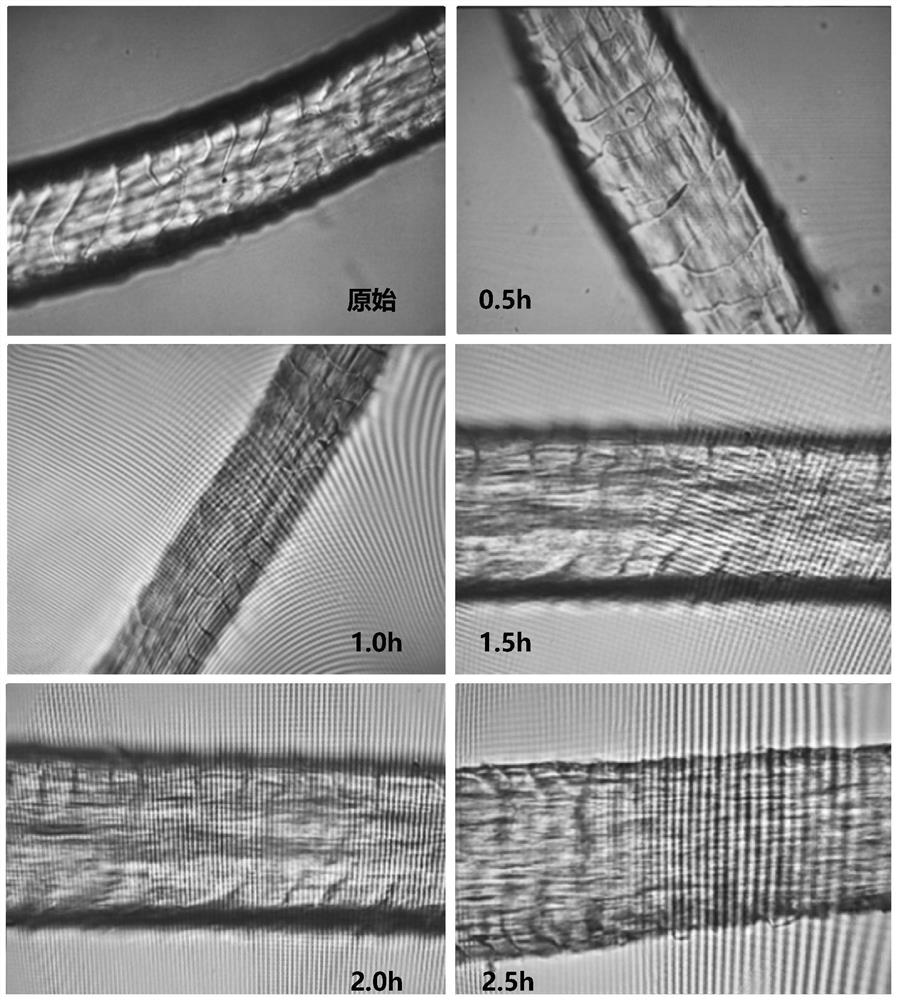

[0063] (1)-(4) The experimental procedures are as the steps (1)-(4) of Example 1, wherein the wool is treated in the sodium sulfide / urea / sodium lauryl sulfate system for 1 h.

[0064] (5) Detection method of enzyme activity: the activity determination reaction system of amino acid dehydrogenase comprises 500 μ L, 4 mM NADH, 8000 μ L, pH 9.5 concentration is 200 mM ammonium chloride-ammonia water as amino donor, 500 μ L, 40 mM substrate solution, The substrate is α-ketoglutaric acid, and samples are taken every 1 min to measure the absorbance of the reaction solution at a wavelength of 340 nm. Enzyme activity is defined as the amount of enzyme required to consume (or generate) 1 μmol NADH per minute under the above conditions, which is an enzyme activity unit.

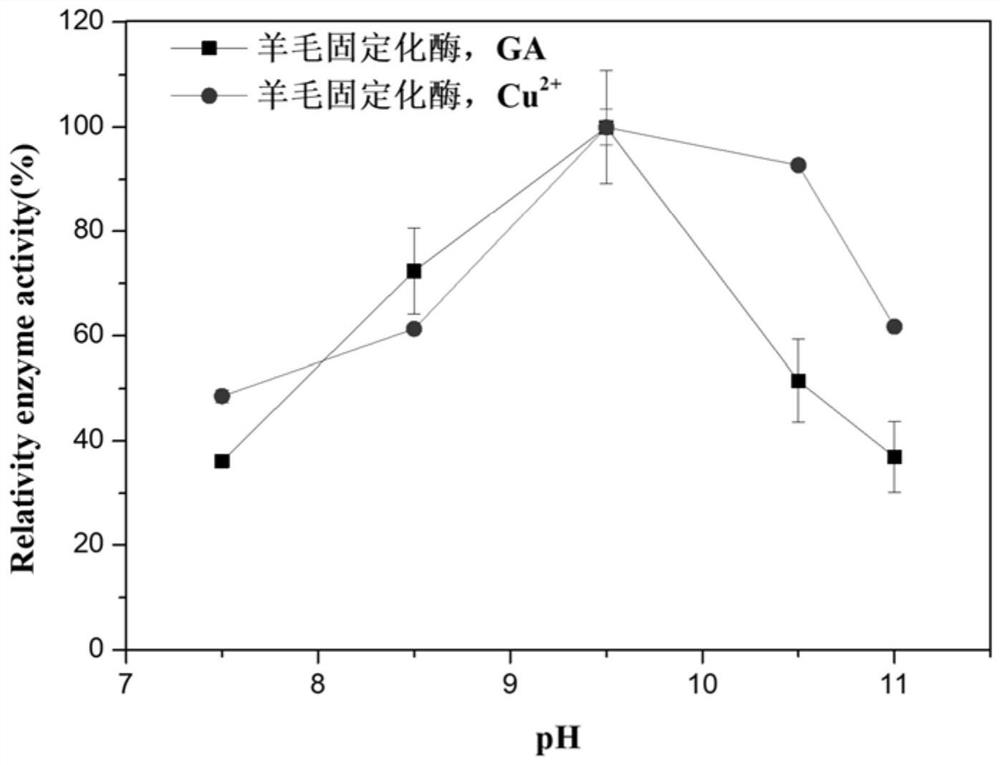

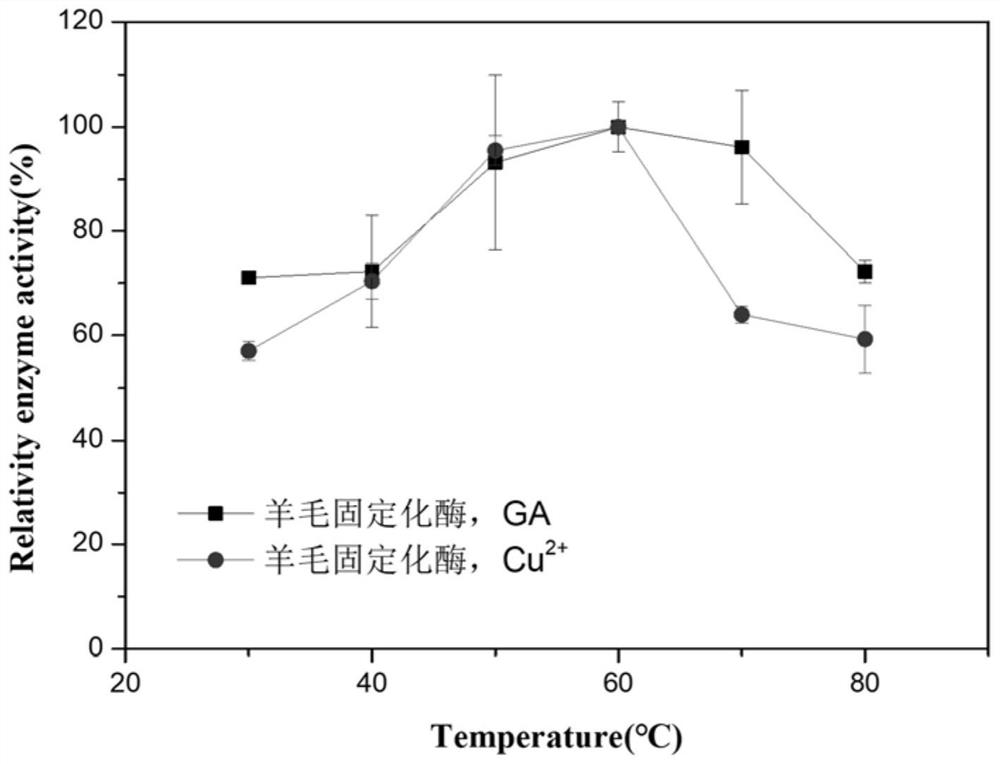

[0065] The amino acid dehydrogenase enzyme activity assay system is a buffer solution at different temperatures (buffer temperature includes 30°C, 40°C, 50°C, 60°C, 70°C, 80°C), to investigate the reaction system to GA ...

Embodiment 3

[0067] (1)-(4) The experimental procedures are as the steps (1)-(4) of Example 1, wherein the wool is treated in the sodium sulfide / urea / sodium lauryl sulfate system for 1 h.

[0068] (5) Detection method of enzyme activity: The reaction system for the determination of amino acid dehydrogenase activity includes 500 μL, 4mM NADH, 8000 μL, pH 9.5, ammonium chloride-ammonium water with a concentration range of 200 mM as amino donor, 500 μL, 40 mM substrate solution , the substrate is phenylpyruvate, and samples are taken every 1 min to measure the absorbance of the reaction solution at a wavelength of 340 nm. Enzyme activity is defined as the amount of enzyme required to consume (or generate) 1 μmol NADH per minute under the above conditions, which is an enzyme activity unit.

[0069] (6) Determination of temperature stability of immobilized enzyme: the wool immobilized enzyme cross-linked with GA and metal ion Cu 2+ After the coordination, the wool-immobilized enzyme was kept i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com