Individual calcium phosphate bionic bone tissue bracket and preparation method and application thereof

A calcium phosphate bionic bone and tissue scaffold technology, used in tissue regeneration, prosthesis, medical science, etc., can solve the problem of incomplete osteogenesis of nutrients, achieve complete osteogenesis and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1. Configure BCP (HA: β-TCP is 3:7) slurry with a volume fraction of 15%:

[0075] Weigh 15g of nanoscale BCP (particle size of 1000nm), 35g of nanoscale β-TCP (particle size of 5000nm), and 0.5g of MgO into a ball mill jar, ball mill at a speed of 30r / min for 24h, and sieve to obtain 50g of biphasic Calcium phosphate powder is ready for use; put 50g of biphasic calcium phosphate powder in a ball mill jar, add 1ml of 40% vt ammonium polyacrylate, 5ml of 10% vt polyvinyl alcohol, and 91ml of deionized water and mix thoroughly with 30r / min ball mill for 24h to obtain the volume For the BCP slurry with a fraction of 15%, the biphasic calcium phosphate powder accounts for 15% vt of the slurry, the dispersant accounts for 0.9% vt, and the binder accounts for 4% vt.

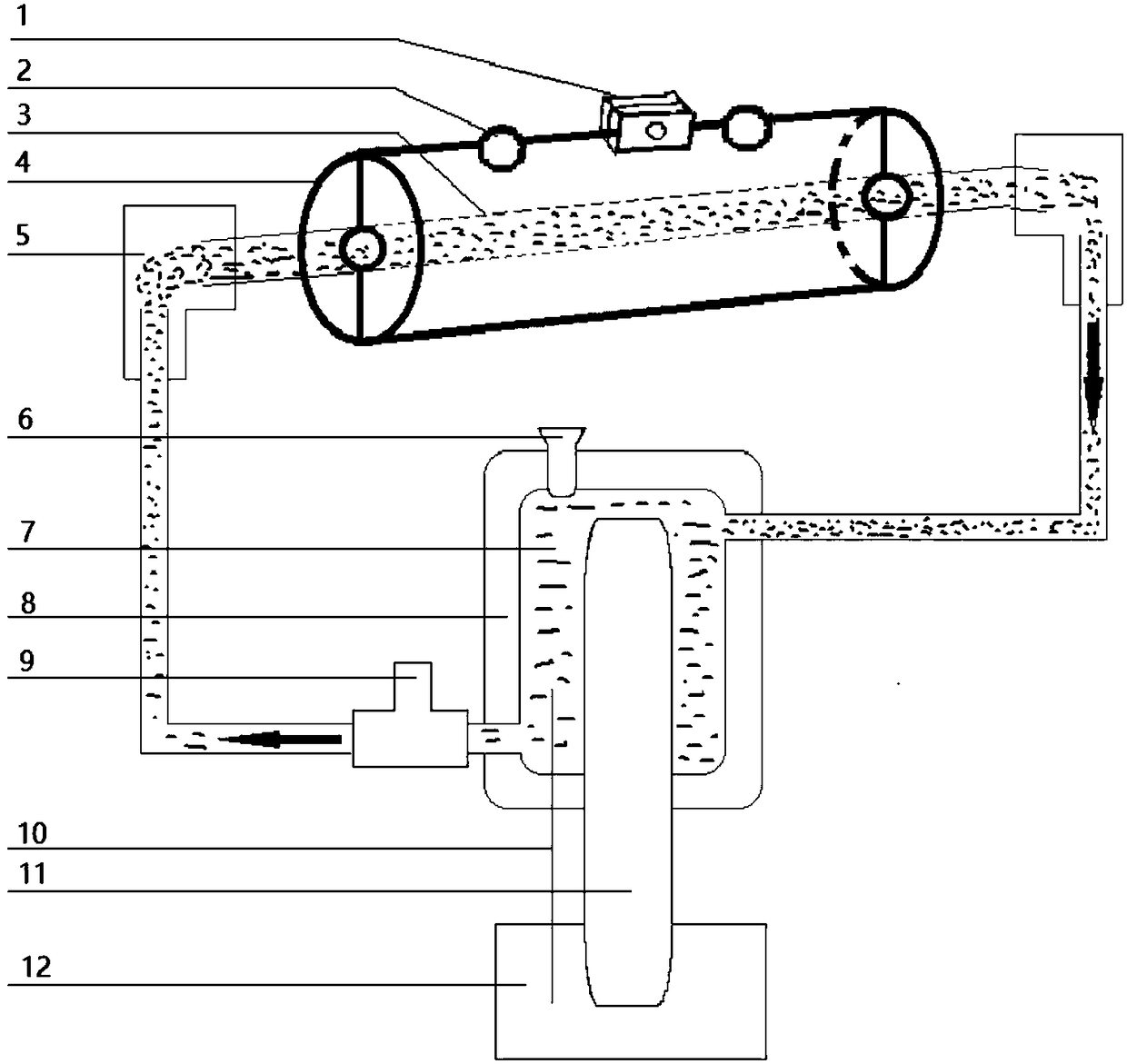

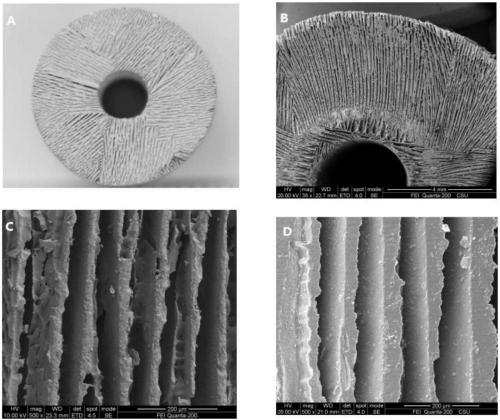

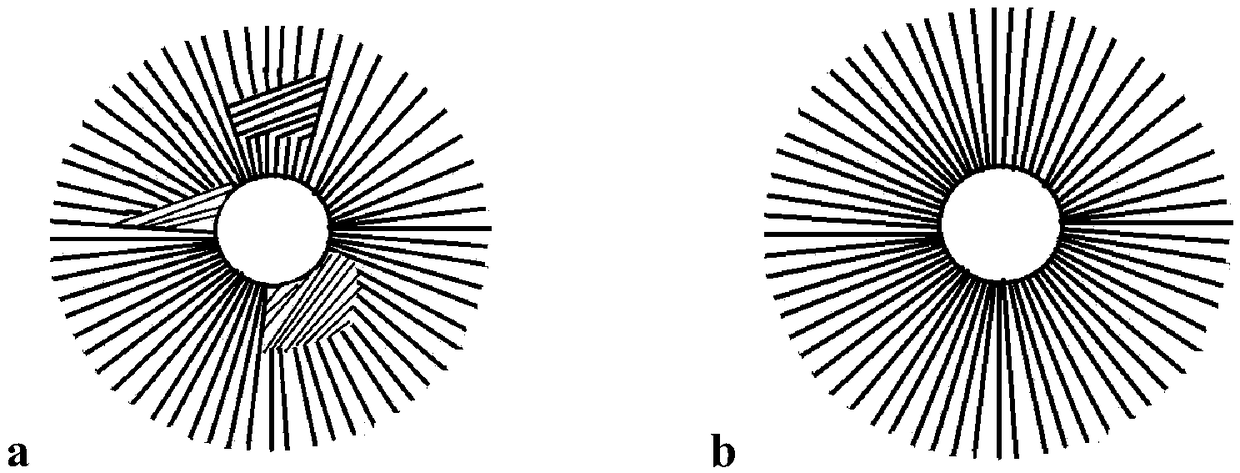

[0076] 2. Slurry freezing and drying:

[0077] Inject the ball-milled slurry into a personalized mold, set the temperature of the cold source to -15°C, control the ambient temperature to 1-4°C, and freeze for 2...

Embodiment 2

[0082] 1. Configure BCP (HA: β-TCP is 2:8) slurry with a volume fraction of 20%:

[0083] Weigh 10g of nanoscale BCP (particle size of 1000nm), 40g of nanoscale β-TCP (particle size of 5000nm), and 0.5g of MgO into a ball mill jar, ball mill for 24 hours at a speed of 30r / min, and sieve to obtain 50g of biphasic Calcium phosphate powder is ready for use; put 50g of biphasic calcium phosphate powder in a ball mill tank, add 61.3ml of deionized water, 1ml of 40% vt ammonium polyacrylate, 2.5ml of 10% vt polyvinyl alcohol and mix thoroughly by ball milling at 30r / min for 24h. A BCP slurry with a volume fraction of 20% was obtained, wherein the biphasic calcium phosphate powder accounted for 30% vt of the slurry, the dispersant accounted for 1.2% vt, and the binder accounted for 3% vt.

[0084] 2. Slurry freezing and drying

[0085] Inject the ball-milled slurry into a personalized mold, set the temperature of the cold source to -20°C, control the ambient temperature to 1-4°C, an...

Embodiment 3

[0089] 1. Configure BCP (HA: β-TCP is 4:6) slurry with a volume fraction of 25%:

[0090] Weigh 20g nanoscale BCP (particle size is 5000nm), 30g nanoscale β-TCP (particle size is 1000nm), 0.5gMgO, put them into a ball mill jar, ball mill at a speed of 30r / min for 12h, and sieve to obtain 50g biphasic Calcium phosphate powder is ready for use; put 50g of biphasic calcium phosphate powder in a ball mill tank, add 48ml of deionized water, 0.8ml of 40% vt ammonium polyacrylate, 3.5ml of 10% vt polyvinyl alcohol and mix thoroughly by ball milling at 30r / min for 24h. A BCP slurry with a mass fraction of 25% was obtained, wherein the biphasic calcium phosphate powder accounted for 25% vt of the slurry, the dispersant accounted for 1.2% vt, and the binder accounted for 5.4% vt.

[0091] 2. Slurry freezing and drying

[0092] Inject the ball-milled slurry into a personalized mold, set the temperature of the cold source to -25°C, control the ambient temperature at 1-4°C, and freeze for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com