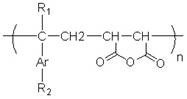

A kind of aqueous phase ultrasonic synthesis method of maleic anhydride/α-arylene copolymer

A maleic anhydride and ultrasonic synthesis technology, applied in the field of organic polymer synthesis, can solve the problems of slow reaction rate, high reaction temperature, and high pollution of organic solvents, and achieve the effect of improving initiation efficiency and reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

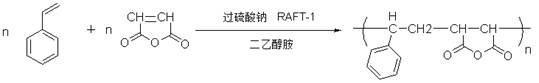

Embodiment 1

[0047]

[0048] Add 40.000 g of deionized water, 9.806 g of maleic anhydride, 0.101 g of RAFT-1 reagent, 0.101 g of sodium persulfate and 0.049 g of diethanolamine into the polymerization reactor, and perform ultrasonic activation treatment for 0.5 to 5 minutes, during which the temperature is controlled at 25°C . Add 10.415 g of styrene slowly, and continue the reaction for 10 min after the addition; add an appropriate base to adjust the pH to 7, and obtain a clear maleic anhydride / styrene polymer aqueous solution. The viscosity-average molecular weight of the polymer is 18000, and the molecular weight distribution is 2.1.

Embodiment 2

[0050]

[0051]Add 40.000 g of deionized water, 9.806 g of maleic anhydride, 0.202 g of RAFT-1 reagent, 0.202 g of sodium persulfate and 0.049 g of diethanolamine into the polymerization reactor, and perform ultrasonic activation treatment for 1 min, during which the temperature is controlled at 27 °C. Slowly add 10.415 g of styrene, and continue the reaction for 14 min after the addition; add an appropriate base to adjust the pH to 7, and obtain a clear maleic anhydride / styrene copolymer aqueous solution. The viscosity-average molecular weight of the polymer is 18000, and the molecular weight distribution is 1.8.

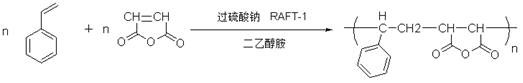

Embodiment 3

[0053]

[0054] Add 40.000 g of deionized water, 9.806 g of maleic anhydride, 0.202 g of RAFT-3 reagent, 0.202 g of sodium persulfate and 0.049 g of diethanolamine into the polymerization reactor, and perform ultrasonic activation treatment for 2 minutes, during which the temperature is controlled at 30°C. Slowly add 10.415 g of styrene, and continue to react for 18 minutes after the addition; add an appropriate base to adjust the pH to 7, and obtain a clear maleic anhydride / styrene copolymer aqueous solution. The viscosity-average molecular weight of the polymer is 10000, and the molecular weight distribution is 2.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com