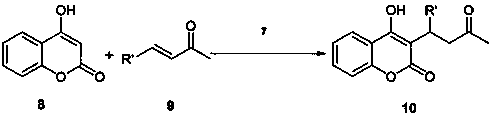

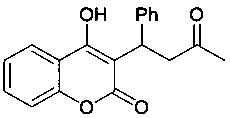

Preparation method of guanidine polymer heterogeneous catalyst and its application method in catalytic synthesis of warfarin and its derivatives

A technology of heterogeneous catalysts and application methods, which is applied in the preparation of guanidine polymer heterogeneous catalysts and the application field of catalytic synthesis of warfarin and its derivatives, which can solve the problems of increasing reaction costs and operating steps, and achieve mild conditions , wide application range and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

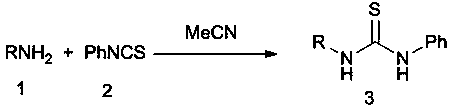

[0029] Example 1: Synthesis of Diphenyl-Substituted Guanidine Polymers

[0030] Take 1.86 g of aniline and 2.71 g of phenyl isothiocyanate dissolved in 50 mL of acetonitrile, stir at room temperature for 6 hours, a large amount of white precipitate appears, filter and dry to obtain 4.22 g of white solid, yield 92.5%.

[0031] Take 2.28 g of N,N'-diphenylthiourea obtained in the previous step, dissolve it in 50 mL of dichloromethane, then add 3.03 g of triethylamine, and finally add 5.11 g of 2-chloro-1-methyliodopyridine, Stir at room temperature for 30 minutes, filter, spin the filtrate to remove the solvent, and separate and purify by column chromatography (eluent: petroleum ether) to obtain 1.57 g of a colorless transparent liquid with a yield of 81.0%.

[0032] 1.57 g (about 8 mmol) of diphenylcarbodiimide obtained in the previous step was dissolved in 20 mL of dichloromethane, and 0.473 g of branched polyethyleneimine (1 mmol equivalent, molecular weight 10,000) was added...

Embodiment 2

[0034] Embodiment 2: the synthesis of phenyl, benzyl substituted guanidine polymer

[0035] Take 2.14 g of benzylamine and 2.71 g of phenyl isothiocyanate dissolved in 50 mL of acetonitrile, stir at room temperature for 6 hours, a large amount of white precipitate appears, filter and dry to obtain 4.56 g of white solid, yield 94.0%.

[0036] Take 2.42 g of thiourea obtained in the previous step, dissolve it in 50 mL of dichloromethane, then add 3.03 g of triethylamine, and finally add 5.11 g of 2-chloro-1-methyliodopyridine, stir at room temperature for 30 minutes, and filter. After the filtrate was spun to remove the solvent, it was separated and purified by column chromatography (eluent: petroleum ether) to obtain 1.66 g of a colorless transparent liquid with a yield of 79.8%.

[0037] 1.66 g (about 7.9 mmol) of the carbodiimide obtained in the previous step was dissolved in 20 mL of dichloromethane, and 0.473 g of branched polyethyleneimine (1 mmol equivalent, molecular wei...

Embodiment 3

[0039] Embodiment 3: the synthesis of phenyl, n-hexyl substituted guanidine polymer

[0040] 2.02 g of n-hexylamine and 2.71 g of phenylisothiocyanate were dissolved in 50 mL of acetonitrile, and stirred at room temperature for 6 hours, a large amount of white precipitate appeared, which was filtered and dried to obtain 4.12 g of white solid with a yield of 87.1%.

[0041] Take 2.36 g of thiourea obtained in the previous step, dissolve it in 50 mL of dichloromethane, then add 3.03 g of triethylamine, and finally add 5.11 g of 2-chloro-1-methyliodopyridine, stir at room temperature for 30 minutes, and filter. After the filtrate was spun to remove the solvent, it was separated and purified by column chromatography (eluent: petroleum ether) to obtain 1.26 g of a colorless transparent liquid with a yield of 62.3%.

[0042] 1.26 g (about 6.23 mmol) of the carbodiimide obtained in the previous step was dissolved in 20 mL of dichloromethane, and 0.368 g of branched polyethyleneimine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com