Method for low-temperature plasma induced synthesis and regulation of covalent organic frame material

A plasma and reactor technology, which is applied in the field of preparation of covalent organic framework materials, can solve the problems of direct synthesis and crystal form regulation that have not been reported, and the long time of COF-1 materials, achieving great academic research value and saving reagents. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Preparation of COF-5 material

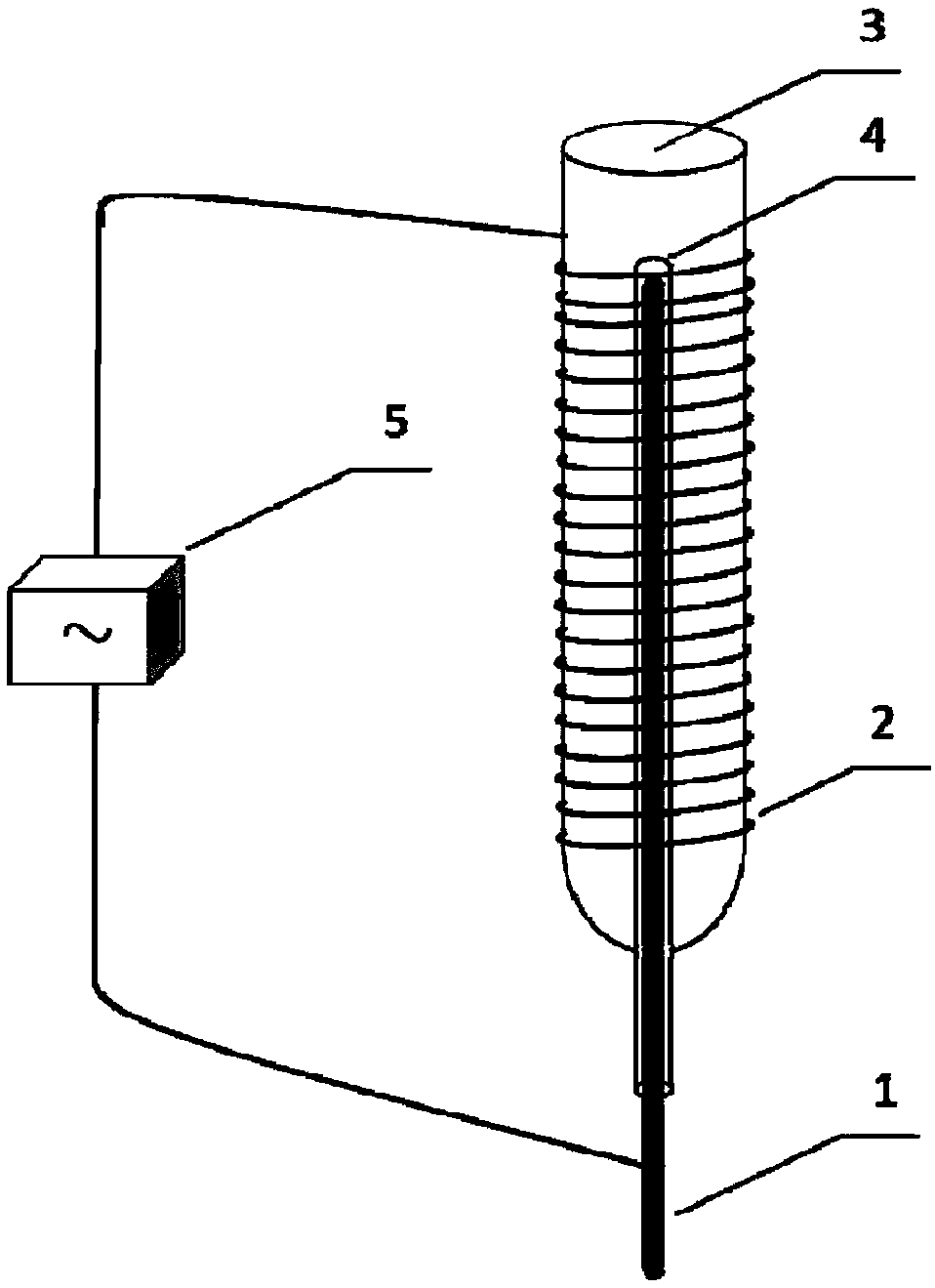

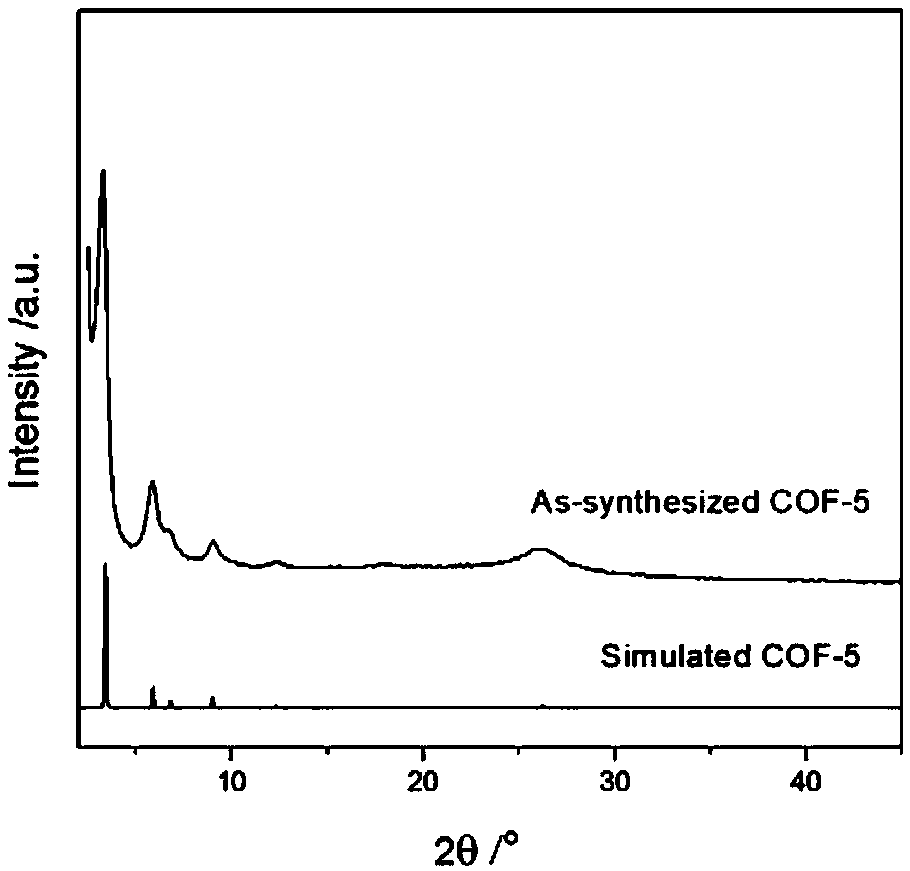

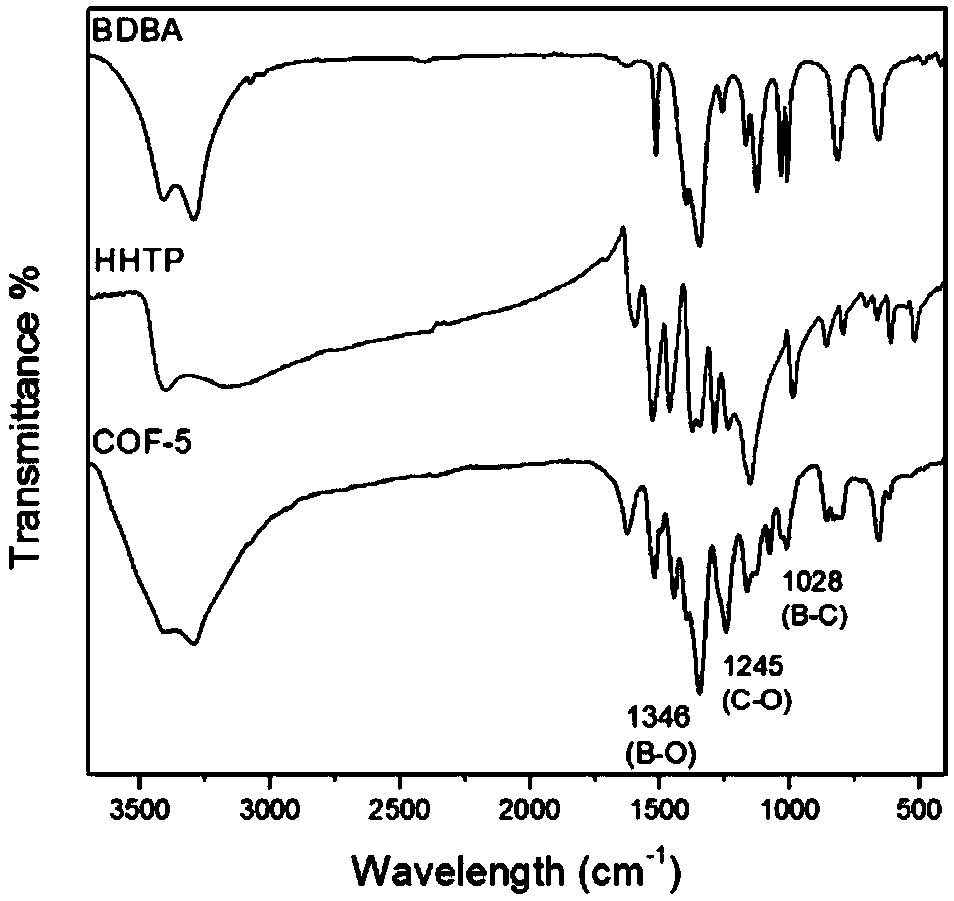

[0055] Weigh 26mg terephthalic acid (BDBA) and 30mg 2,3,6,7,10,11-hexahydroxytriphenyl (HHTP) in a beaker, add 3mL dimethylformamide and 4mL mesitylene as solvent, Ultrasonic for 3 minutes until evenly dispersed, put the mixed solution into the liquid discharge plasma reactor, connect the inner and outer electrodes (tungsten rod and wound copper wire) of the dielectric barrier discharge reactor to the high-voltage AC power supply respectively, turn on the power supply and adjust The voltage is 32V and the current is 1.1A. At this time, the device emits a blue-violet light and the solution begins to boil. After reacting for 8 minutes, the power was turned off to end the reaction. The product was filtered with suction and washed twice with DMF and three times with acetone, and then dried in a vacuum oven at 80° C. for 12 hours. The gray product (COF-5) was subjected to powder X-ray diffraction (XRD) and Fourier transform infr...

Embodiment 2

[0056] Embodiment 2: Preparation of COF-10 material

[0057] Weigh 50mg biphenyl diboronic acid (BPDA) and 44mg 2,3,6,7,10,11-hexahydroxytriphenyl (HHTP) in a beaker, add 3mL dimethylformamide and 4mL mesitylene as solvent, Ultrasonic for 3 minutes until evenly dispersed, put the mixed solution into the liquid discharge plasma reactor, connect the inner and outer electrodes (tungsten rod and wound copper wire) of the dielectric barrier discharge reactor to the high-voltage AC power supply respectively, turn on the power supply and adjust The voltage is 32V and the current is 1.1A. At this time, the device emits a blue-violet light and the solution begins to boil. After reacting for 10 minutes, the power was turned off to end the reaction. The product was filtered with suction and washed twice with DMF and three times with acetone, and then dried in a vacuum oven at 80° C. for 12 hours. The gray product (COF-10) was subjected to powder X-ray diffraction (XRD) and Fourier trans...

Embodiment 3

[0058] Embodiment 3: preparation NUS-2 material

[0059] Weigh 63 mg of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde (Tp), dissolve it in 7 mL of dimethylformamide, then add 36 μL of hydrazine hydrate, transfer the reaction mixture and react with plasma In the tube, turn on the power and adjust the voltage to 33V, the current to 1.15A, and the response time to 10min. The obtained NUS-2 material was washed three times with DMF and ethanol and dried. The characterization results are shown in the attached Pic 4-1 ,4-2 and Figure 4-3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com