Antibacterial and anti-corrosion capsaicine composite ZnO/Zn coating layer as well as preparation and application thereof

A composite coating, capsaicin technology, applied in coatings, electrolytic coatings, etc., can solve problems such as environmental pollution, microbial corrosion and biofouling, and achieve enhanced corrosion resistance and antibacterial activity, environmentally friendly anti-biofouling, environmental protection. Friendly and resistant to microbial corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of capsaicin composite ZnO / Zn electroplating layer:

[0028] 1) Preparation of alkaline zinc plating solution system: 16g / L NaOH, 2.0g / L ZnO, dissolved in distilled water, and used for JBlank.

[0029] Then add 0.2g / L, 0.6g / L and 1.0g / L capsaicin to JBlank respectively, stir for half an hour and let it stand, respectively as JC1, JC2 and JC3.

[0030] 2) Using 20# standard carbon steel sheet as the base material, polish each surface of the test piece with 80#, 400#, 1000#, 2000# sandpaper water-phase sandpaper, put it in absolute ethanol and ultrasonically for 10 minutes to remove the oil on the surface, Then immerse the bare part of the test piece in 1mol / L HCl for 5s to activate its surface, and set it aside.

[0031] 3) Use the DJS-292E potentiostat, adjust to the constant current mode, connect the steel to be protected in step 2) to the negative pole of the DC power supply, and connect the positive pole of the DC power supply with a pure zinc sheet of t...

Embodiment 2

[0035] Evaluation of microbial corrosion resistance of capsaicin composite ZnO / Zn electroplating coating:

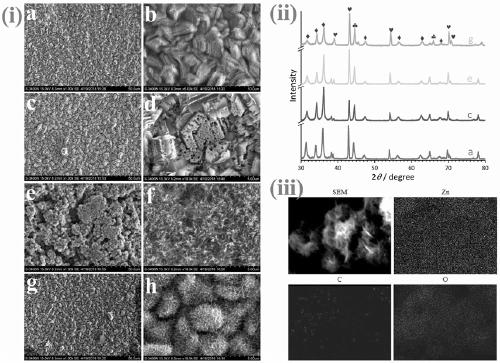

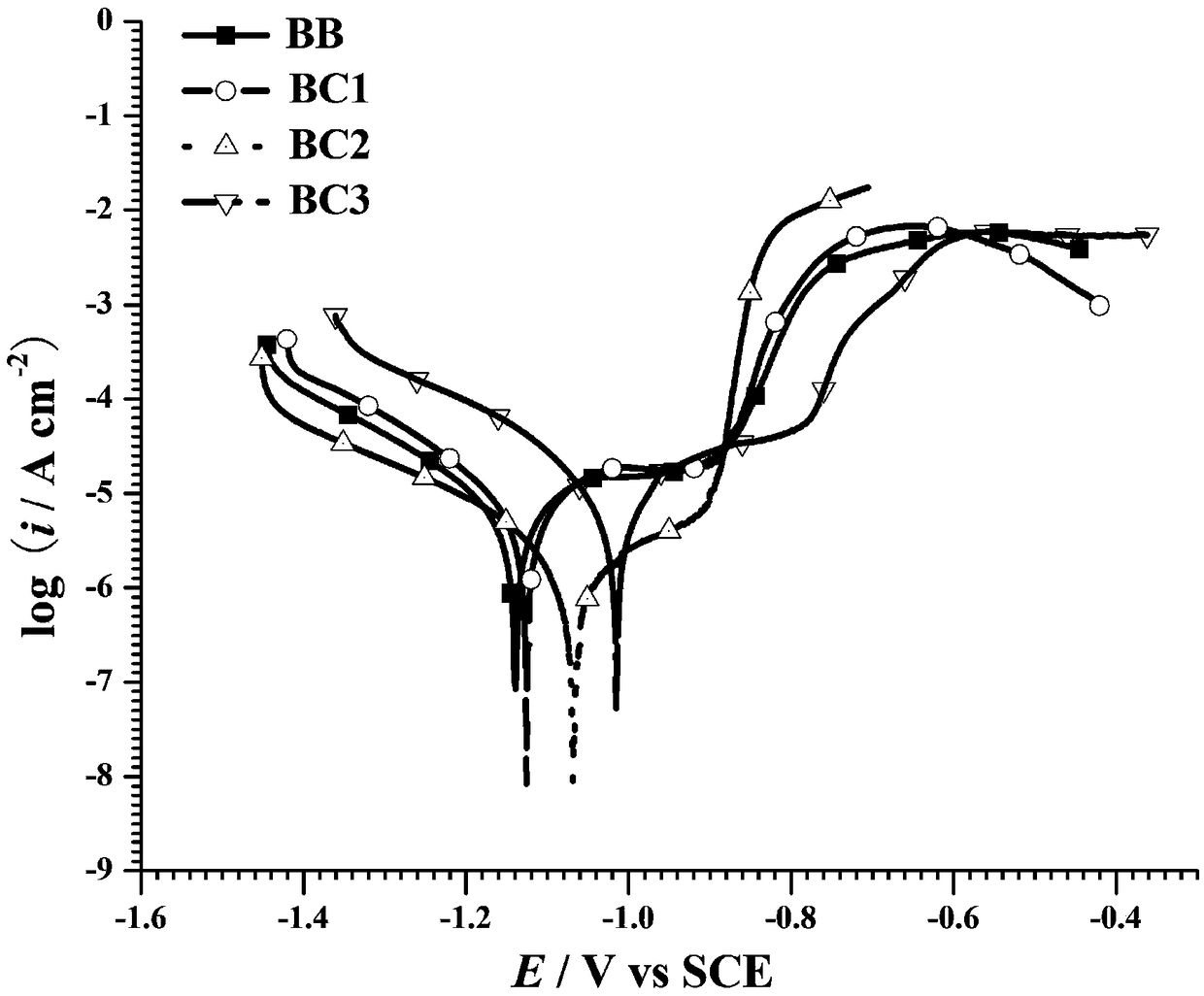

[0036] Prepare the sulfate plating solution system JBlank and JC1, JC2 and JC3 according to the steps in Example 1, at 15mA cm -2 Constant current deposition under the current density for 20min, the obtained composite zinc coatings are BB, BC1, BC2 and BC3, and the electroplating layer is subsequently processed according to the step (4) in Example 1. Subsequently, the prepared BB, BC1, BC2 and BC3 coatings were immersed in typical marine corrosion microbial sulfate reducing bacteria (SRB, Desulfovibriocaledoniensis) for 14 days, and the Tafel curve was used to evaluate the corrosion resistance of BB, BC1, BC2 and BC3 coatings (Such as figure 2 shown). It can be seen from the polarization curve that as the concentration of capsaicin increases, the self-corrosion potential of the coating shifts positively, indicating that its corrosion sensitivity decreases; however, th...

Embodiment 3

[0038] Antibacterial performance evaluation of capsaicin composite ZnO / Zn electroplating layer:

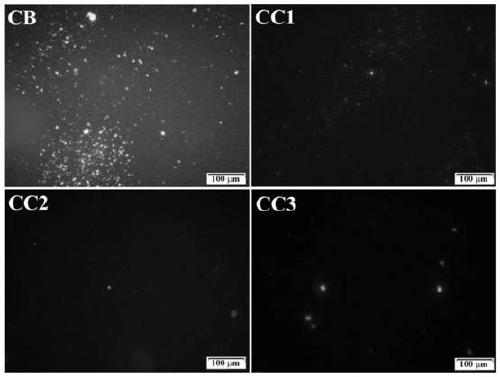

[0039] Prepare the sulfate plating solution system JBlank and JC1, JC2 and JC3 according to the steps in Example 1, at 25mA cm -2Constant current deposition under the current density for 20min, the obtained composite zinc coatings are CB, CC1, CC2 and CC3, and the electroplating layer is subsequently processed according to the step (4) in Example 1. Subsequently, the prepared CB, CC1, CC2 and CC3 electroplating layers were immersed in 10 7 Soak in cfu / mL E.coliPBS suspension for 24h. After taking it out, add a mixed staining agent (a mixture of 4 mg / L ethidium bromide and 4 mg / L acridine orange), stain at 30°C in the dark for 30 min, and observe with an Olympus fluorescence microscope at 200 times. The bright spot in the figure is the bacteria attached to the surface of the coating. It can be seen from the figure that a large number of live bacteria are attached to the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com