A method for producing polyvinyl chloride artificial leather based on synchronous internal plasticization of photosensitive response plasticizer

A photosensitive reaction, polyvinyl chloride technology, applied in the field of plastic processing, can solve problems such as affecting the quality and service life of finished leather, harm to consumers' health, etc., to inhibit the migration of plasticizers, solve the problem of toxicity, and achieve high compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: luggage leather manufacturing

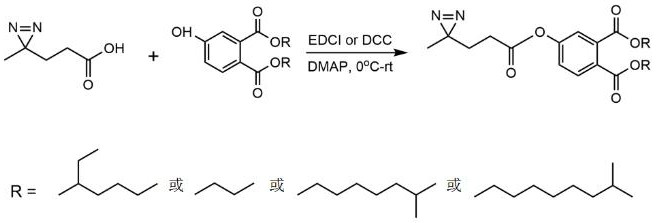

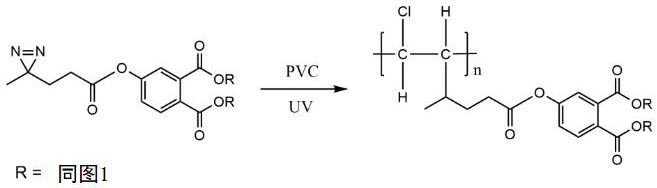

[0020] (1) Preparation of photoresponsive plasticizer: Add 17 parts of 3-methyl-3H-diaziridine-3-propionic acid, 35 parts of 1- Ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 24 parts of 4-dimethylaminopyridine, and keep the mixed system at 0-5 ° C for 10 minutes, then add 50 parts of 4- Add di-isooctyl hydroxyphthalate to the mixture, gradually rise to room temperature, and react for 10 hours. After the reaction, wash twice with 300 parts of 0.5mol / L hydrochloric acid solution and 300 parts of saturated sodium bicarbonate solution respectively , and then washed with 300 parts of distilled water until the pH of the washed water was 6-7, and finally distilled under reduced pressure to obtain a photosensitive reaction type diisooctyl phthalate plasticizer;

[0021] (2) Preparation of polyvinyl chloride tanning slurry: under the condition of avoiding light, the emulsion method polyvinyl chloride resin, photosensitiv...

Embodiment 2

[0025] Example 2: Manufacturing of Upholstery Leather

[0026] (1) Preparation of photoresponsive plasticizer: Add 24 parts of 3-methyl-3H-diaziridine-3-propane to 80 parts of anhydrous N,N-dimethylformamide under light-proof conditions acid, 48 parts of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 33 parts of 4-dimethylaminopyridine, and keep the mixed system at 0-5 ° C for 15 minutes, Then add 50 parts of 4-hydroxy dibutyl phthalate to the mixture, gradually rise to room temperature, and react for 10 hours. Each solution was washed twice, then washed with 300 parts of distilled water until the pH of the washed water was 6-7, and finally distilled under reduced pressure to obtain a photosensitive reaction type dibutyl phthalate plasticizer;

[0027] (2) Preparation of polyvinyl chloride tanning slurry: under light-proof conditions, according to conventional methods, the emulsion method polyvinyl chloride resin, photosensitive reaction type dibutyl phthalate pl...

Embodiment 3

[0031] Embodiment 3: the manufacture of automobile interior leather

[0032] (1) Preparation of photoresponsive plasticizer: Add 30 parts of 3-methyl-3H-diaziridine-3-propionic acid, 67 parts of Cyclohexylcarbodiimide, 42 parts of 4-dimethylaminopyridine, and keep the mixed system at 0-5 ° C for 20 minutes, then add 100 parts of 4-hydroxy diisodecyl phthalate to the mixture, gradually Rise to room temperature and react for 12 hours. After the reaction, wash twice with 500 parts of 0.5mol / L hydrochloric acid solution and 300 parts of saturated sodium bicarbonate solution, and then wash with 300 parts of distilled water until the pH of the washing water is 6-7 , and finally distilled under reduced pressure to obtain a photosensitive reaction type diisodecyl phthalate plasticizer;

[0033] (2) Preparation of polyvinyl chloride tanning slurry: Under light-proof conditions, according to conventional methods, compound polyvinyl chloride resin by emulsion method, photosensitive reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com