Selenium-enriched rice extract, and preparation method and application thereof

A technology of selenium-enriched rice and extracts, which is applied in the direction of food ingredients, applications, and food science containing natural extracts, can solve the problems of no extraction method and low selenium content, so as to improve tranquility, improve the quality of life, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

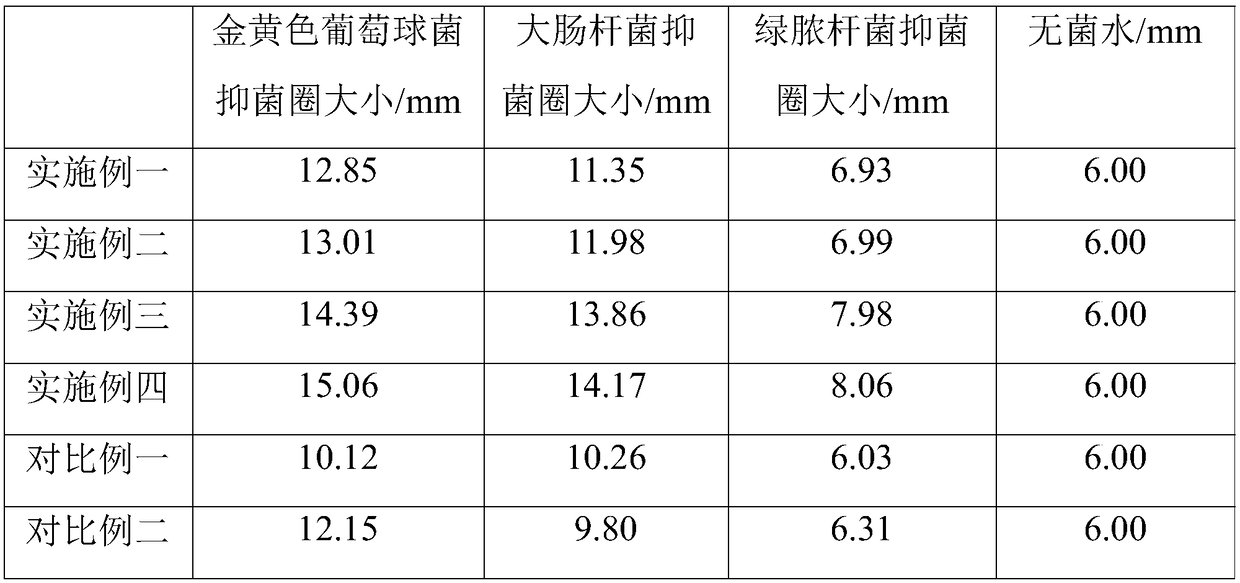

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of rice extract, comprises the following steps:

[0025] S1: Wash the selenium-enriched rice, dry it, and crush it. Soak the crushed rice in water, add amylase and protease, ultrasonically treat it for 15-30 minutes, shake it at constant temperature for 2-4 hours, and centrifuge at a speed of 1500-2000 rpm After 3-5 minutes, the supernatant was collected to obtain the enzymatic hydrolyzed slurry. Wherein, the selenium content of the selenium-enriched rice is 30-100 μg / kg, and preferably 60-80 μg / kg; the mass ratio of rice, amylase and protease is 100: (5-15): (2-5) .

[0026] S2: Mix the enzymatically hydrolyzed slurry and compound solution evenly according to the mass ratio of 1: (0.1-10), and then perform microwave extraction for 20-60 minutes at a power of 1.5-2.5kW and a temperature of 50-65°C. Filter and collect the filtrate. Wherein, the raw material components of the compound liquid include: 1-3 parts by weig...

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of rice extract, comprises the following steps:

[0032] S1: Wash the selenium-enriched rice, dry it, and crush it. Soak the crushed rice in water, then add amylase and protease, sonicate for 30 minutes, shake at constant temperature for 2 hours, centrifuge at 2000rpm for 3 minutes, and collect the supernatant , that is, the slurry after enzymolysis is obtained. Among them, the selenium content of selenium-enriched rice is 80 μg / kg; the mass ratio of rice, amylase and protease is 100:5:5.

[0033] S2: Mix the enzymolyzed slurry and compound solution evenly at a mass ratio of 1:1, then extract with microwaves for 60 minutes at a power of 2.5kW and a temperature of 50°C, filter and collect the filtrate. Wherein, the raw material components of the compound liquid include: 1 weight part of citric acid, 0.8 weight part of sodium chloride, 1 weight part of green tea and 100 weight parts of water in parts by weight....

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of rice extract, comprises the following steps:

[0037] S1: Wash the selenium-enriched rice, dry it and crush it, soak the crushed rice in water, then add amylase and protease, sonicate for 15 minutes, then shake at constant temperature for 4 hours, centrifuge at 1500rpm for 5 minutes, and collect the supernatant , that is, the slurry after enzymolysis is obtained. Among them, the selenium content of selenium-enriched rice is 60 μg / kg; the mass ratio of rice, amylase and protease is 100:15:2.

[0038] S2: Mix the enzymatic hydrolyzed slurry and compound solution evenly at a mass ratio of 1:10, then extract by microwave at a power of 1.5kW and a temperature of 65°C for 20min, filter and collect the filtrate. Wherein, the raw material components of the compound liquid include: 3 parts by weight of citric acid, 0.1 parts by weight of sodium chloride, 2 parts by weight of green tea and 100 parts by weight of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com