Production method of ferric pyrophosphate to be added into foods containing vitamins

A technology of iron pyrophosphate and production method, applied in the directions of food ingredients, food science, application, etc., can solve the problems of poor dispersibility of ordinary iron pyrophosphate, adverse effects on dietary health, affecting the appearance of food, etc., and achieves improved processing performance, flowability good, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of ferric pyrophosphate powder added to vitamin-containing foods

[0019] First, the commercially available ferric pyrophosphate raw material is ultrafinely pulverized to form an ultrafine powder of about 10 μm for use;

[0020] Put 100Kg of ultra-finely pulverized iron pyrophosphate powder, 20Kg of polyacrylic acid resin III, 70Kg of sodium starch octenyl succinate, and 10Kg of calcium gluconate in 1000Kg of purified water, stir to form a suspension, and then use a 2-ton preparation tank Perform high-speed shearing and homogenization (for 55-60 minutes) at a speed of 20-25 rpm, and finally send the emulsion into the spray drying tower for spray drying, keep the inlet air temperature of the spray drying tower at 180 °C, The wind temperature is 90°C, and the spray-dried powder is sieved through 80 mesh, weighed and packaged for storage.

[0021] When used as a food fortifier, it should be added at 10% of the total weight of the material, and evenly...

Embodiment 2

[0022] Example 2 Preparation of ferric pyrophosphate powder added to vitamin-containing foods

[0023] Similarly, the commercially available ferric pyrophosphate raw material is ultrafinely pulverized to form an ultrafine powder of about 10 μm for use;

[0024] Put 150Kg of ultra-finely pulverized iron pyrophosphate powder, 25Kg of polyacrylic acid resin III, 70Kg of sodium starch octenyl succinate, 5Kg of calcium gluconate into 1000Kg of purified water, stir evenly to form a suspension, and then use a 2-ton preparation tank Perform high-speed shearing and homogenization (for 55-60 minutes) at a speed of 20~25 rpm, and finally send the emulsion into the spray drying tower for spray drying, keep the inlet air temperature of the spray drying tower at 170 °C, The air temperature is 85°C, and the spray-dried powder is sieved through 100 mesh, weighed and packaged for storage.

[0025] When used as a food fortifier, it should be added at 10% of the total weight of the material, an...

Embodiment 3

[0026] Embodiment 3 The performance comparison of ferric pyrophosphate produced by the present invention and commercially available ferric pyrophosphate

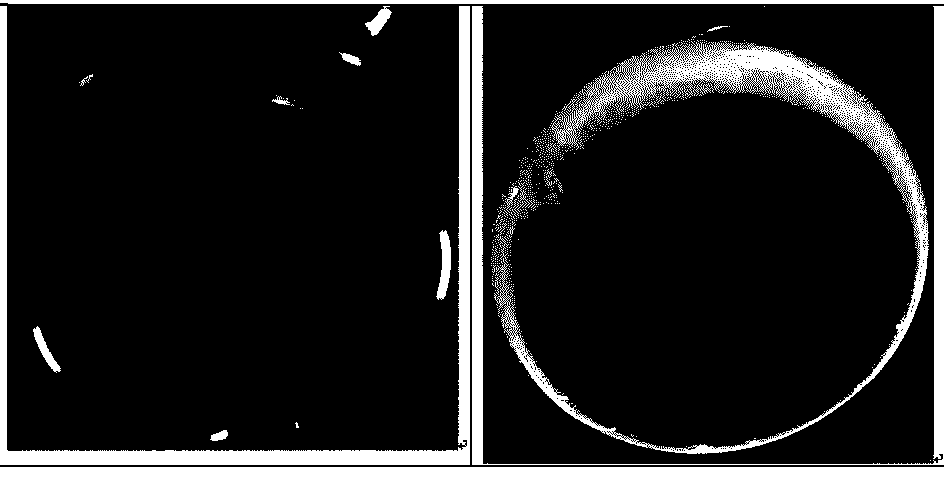

[0027] Common commercially available ferric pyrophosphate and the finished powder of ferric pyrophosphate produced in Example 1 of the present invention were mixed with vitamin C in the same proportion, and then the brewing experiment was carried out. The result is as figure 1 shown.

[0028] figure 1 The picture on the left in the center shows the solution prepared by vitamin C containing conventional ferric pyrophosphate, and the black precipitate produced after the reaction can be clearly shown in the picture; After adjusting the solution, it can be seen that the solution is clear and no black precipitate is produced.

[0029] The ferric pyrophosphate produced by the present invention is added in vitamin-containing nutritious food as an iron-fortified element, and the iron content in the solution is measured after weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com