Nickel/cobalt-modified molybdenum disulfide nanoflower material as well as synthetic method and application thereof

A technology of molybdenum disulfide and synthesis method, which is applied in chemical instruments and methods, carbon compound catalysts, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of limited number of active sites, poor adjustment of synthesis morphology and small specific surface area. and other problems to achieve the effect of increasing the effective contact area, reducing the phenomenon of stacking and agglomeration, and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

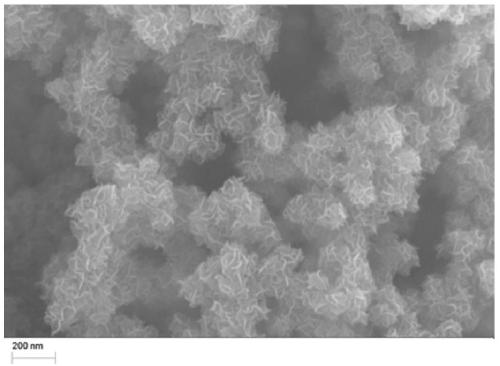

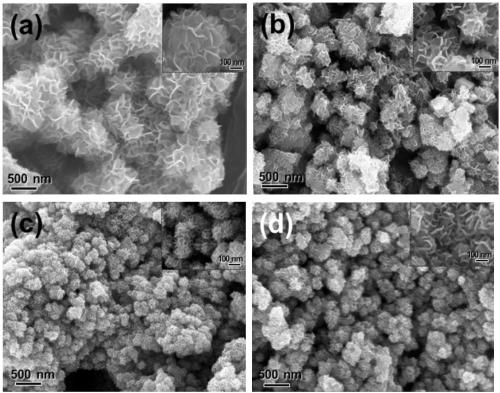

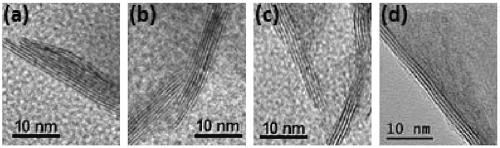

[0024] Weigh 2.0 g of ammonium molybdate and 1.64 g of nickel nitrate and dissolve them in 18 mL of water to form a uniform solution. During stirring, add 10 mL of hydrazine hydrate solution (85%) and mix well. Weigh 1.45g of elemental sulfur, add the above solution, and perform ultrasonication for 30min. Then put the obtained mixed solution into a polytetrafluoroethylene-lined container, and put it into an oven for hydrothermal reaction. The hydrothermal temperature is 180°C, and the hydrothermal time is 72h. After the reaction, cooling was performed, and the reacted mixed solution was taken out for separation and washing. The obtained black solid was treated in a vacuum oven at 60° C. for 24 hours, and finally nickel-modified molybdenum disulfide three-dimensional nanoflower material was obtained. The scanning and transmission electron micrographs of the material synthesized by this method are as follows: figure 2 (a) and image 3 (a) shown. It can be seen from the fig...

Embodiment 2

[0026] Example 2 is basically the same as Example 1, except that the amount of each precursor is used: 1.0 g of ammonium molybdate, 0.494 g of nickel nitrate, and 0.725 g of elemental sulfur. The scanning and transmission electron micrographs of the material synthesized by this method are as follows: figure 2 (b) and image 3 (b) shown. It can be seen from the figure that the nickel-modified molybdenum disulfide nanoflowers prepared by this method are uniform in shape, the size of the flower ball is about 260nm, and the thickness of the formed flower flakes is about 5.2nm.

Embodiment 3

[0028] Example 3 is basically the same as Example 1, except that the amount of each precursor is used: 0.5 g of ammonium molybdate, 0.41 g of nickel nitrate, and 0.36 g of elemental sulfur. The scanning and transmission electron micrographs of the material synthesized by this method are as follows: figure 2 (c) and image 3 (c) shown. It can be seen from the figure that the nickel-modified molybdenum disulfide nanoflowers prepared by this method are uniform in shape, the size of the flower bulb is about 150 nm, and the thickness of the formed flower flakes is about 4.0 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com