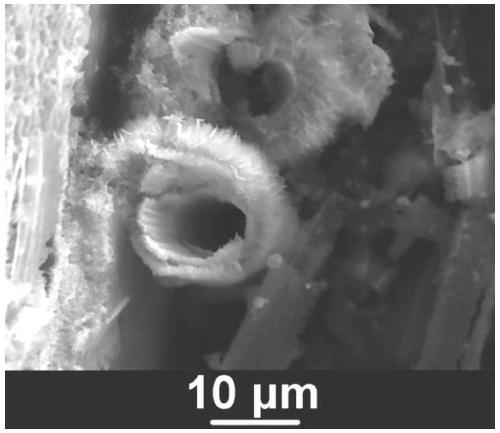

Metal oxide/calcium phosphor double-layer micro-tube, and preparation method thereof

An oxide and micro-tube technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, copper oxide/copper hydroxide, etc., can solve problems such as lack of guidance or induction of human tissue regeneration, chemical composition differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) The carbon fiber is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and then dried in an oven, and the obtained sample is marked as A;

[0024] (2) Place A in a glucose solution with a mass fraction of 10% and soak for 30 minutes, and the resulting sample is marked as B;

[0025] (3) Place B in a vacuum furnace, raise the temperature to 800 degrees at a rate of 20 degrees per hour in an argon-protected environment, keep it warm for 1 hour, and cool naturally to obtain sample C;

[0026] (4) Zinc nitrate is dissolved in deionized water and is mixed with the zinc nitrate aqueous solution that concentration is 10mmol / L, then heated to 50 degree, obtains solution D;

[0027] (5) The graphite sheet is used as the anode, the sample C is the cathode, the cathode and the anode are placed in the solution D in parallel with a distance of 30 mm, and a current of 1 mA is applied for 10 minutes, and then naturally dried in the air to obtain the samp...

Embodiment 2

[0033] (1) The carbon fiber is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and then dried in an oven, and the obtained sample is marked as A;

[0034] (2) Place A in a glucose solution with a mass fraction of 20% and soak for 60 minutes, and the resulting sample is marked as B;

[0035] (3) Place B in a vacuum furnace, and in an argon-protected environment, raise the temperature to 900 degrees at a heating rate of 30 degrees per hour and keep it warm for 3 hours, and naturally cool to obtain sample C;

[0036] (4) Ferric nitrate is dissolved in deionized water and is mixed with the ferric nitrate aqueous solution that concentration is 100mmol / L, then heated to 80 degree, obtains solution D;

[0037] (5) The graphite sheet is used as the anode, the sample C is the cathode, the cathode and the anode are placed in the solution D in parallel with a distance of 80 mm, and a current of 10 mA is applied for 60 minutes, and then naturally dried in the...

Embodiment 3

[0043] (1) The carbon fiber is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and then dried in an oven, and the obtained sample is marked as A;

[0044] (2) Place A in a glucose solution with a mass fraction of 15% and soak for 40 minutes, and the resulting sample is marked as B;

[0045] (3) Place B in a vacuum furnace, and in an argon-protected environment, raise the temperature to 850 degrees at a rate of 25 degrees per hour and keep it warm for 2 hours, and naturally cool to obtain sample C;

[0046] (4) Copper nitrate is dissolved in deionized water and is mixed with the copper nitrate aqueous solution that concentration is 50mmol / L, then heated to 60 degree, obtains solution D;

[0047] (5) The graphite sheet is used as the anode, the sample C is the cathode, the cathode and the anode are placed in the solution D in parallel with a distance of 50 mm, and a current of 5 mA is applied for 30 minutes, and then naturally dried in the air to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com