Method for degrading sulfadiazine in water by activating persulfate with coagulated sludge

A technology of persulfate and sulfadiazine, applied in the field of harmless treatment of pollutants, can solve the problems of low resource utilization, heavy workload, secondary pollution, etc., and achieve the effect of simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

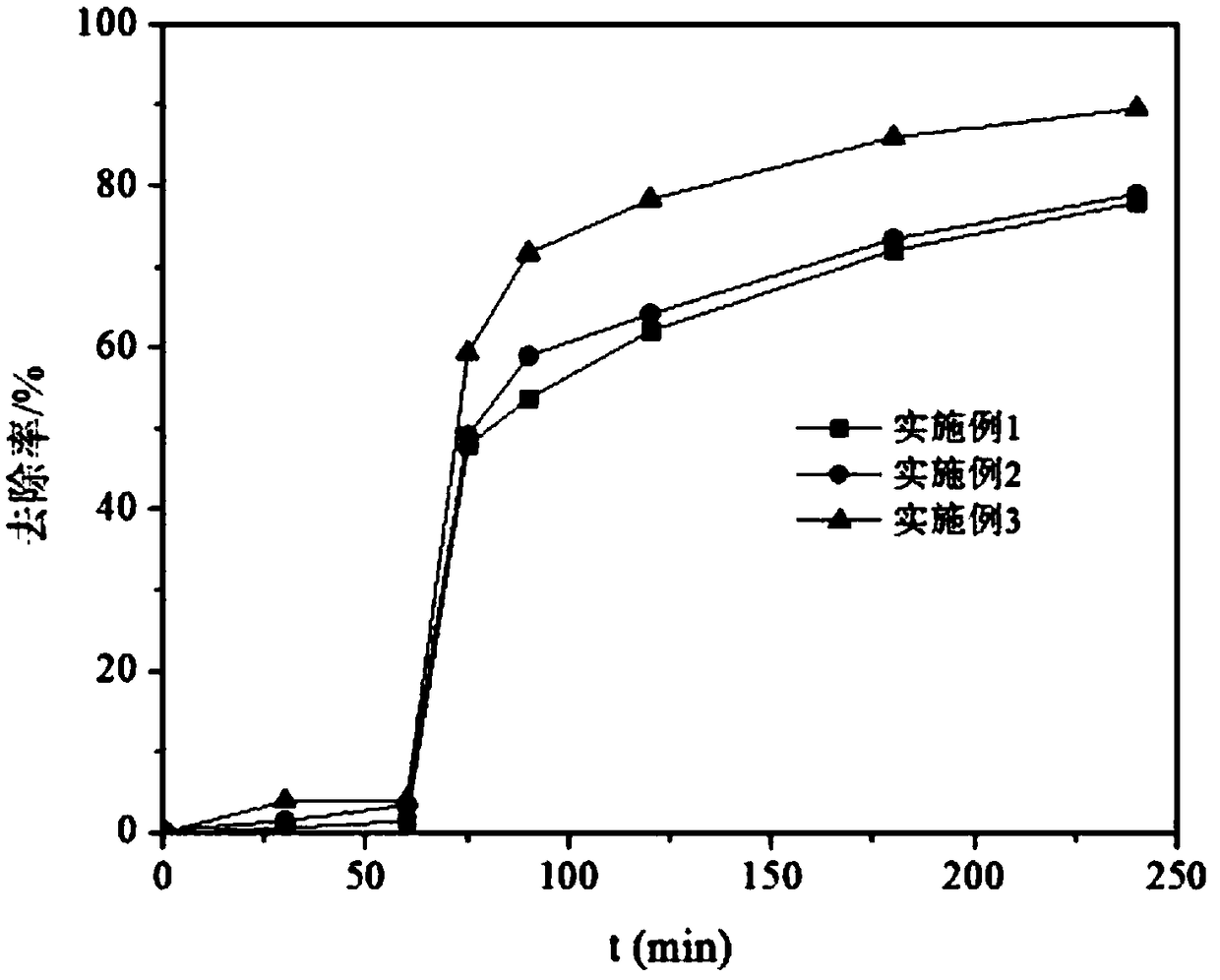

Embodiment 1

[0019] A method utilizing coagulated sludge to activate persulfate to degrade sulfadiazine in water, comprising the following steps:

[0020] 1. Preparation of persulfate activator: air-dry the coagulated sludge naturally, crush it, dry it at 120°C for 2 hours, and crush it through a 120-mesh sieve; take the crushed sludge and put it in a tube furnace, and carry out in a nitrogen atmosphere Pyrolysis, the black carbonized material obtained after cooling, the pyrolysis steps are as follows: firstly, the temperature is raised to 600°C at a rate of 5°C / min, and then naturally cooled to room temperature after staying for 50min; the nitrogen flow rate used is 200mL / min, and the whole pyrolysis process starts from From the beginning of heating up to cooling down to room temperature, nitrogen is used as a protection to prevent material oxidation.

[0021] 2. Black carbonized material is used to activate persulfate to degrade sulfadiazine in water: add carbonized material to sulfadiaz...

Embodiment 2

[0024] A method utilizing coagulated sludge to activate persulfate to degrade sulfadiazine in water, comprising the following steps:

[0025] 1. Preparation of persulfate activator: air-dry the coagulated sludge naturally, crush it, dry it at 120°C for 2 hours, and crush it through a 120-mesh sieve; take the crushed sludge and put it in a tube furnace, and carry out in a nitrogen atmosphere Pyrolysis, the black carbonized material obtained after cooling, the pyrolysis step is to first raise the temperature to 700°C at a rate of 8°C / min, and then cool naturally after staying for 70 minutes; the nitrogen flow rate used is 300mL / min, and the whole pyrolysis process starts from the temperature rise When the temperature is lowered to room temperature, nitrogen is used as protection to prevent material oxidation.

[0026] 2. Black carbonized material is used to activate persulfate to degrade sulfadiazine in water: add carbonized material to sulfadiazine wastewater, and react in a sh...

Embodiment 3

[0029] A method utilizing coagulated sludge to activate persulfate to degrade sulfadiazine in water, comprising the following steps:

[0030] 1. Preparation of persulfate activator: air-dry the coagulated sludge naturally, crush it, dry it at 120°C for 2 hours, and crush it through a 120-mesh sieve; take the crushed sludge and put it in a tube furnace, and carry out in a nitrogen atmosphere Pyrolysis, the black carbonized material obtained after cooling, the pyrolysis steps are as follows: firstly, the temperature is raised to 800°C at a rate of 10°C / min, and then naturally cooled to room temperature after staying for 80min; the nitrogen flow rate used is 400mL / min, and the whole pyrolysis process starts from From the beginning of heating up to cooling down to room temperature, nitrogen is used as a protection to prevent material oxidation.

[0031] 2. Black carbonized material is used to activate persulfate to degrade sulfadiazine in water: add carbonized material to sulfadia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com