Technology used for preparing methyl carbonate quaternary ammonium salt or ethyl carbonate quaternary ammonium salt using loop reaction device

A methyl carbonate and ethyl carbonate technology, which is applied in the preparation of organic carbonates, the preparation of amino compounds, sustainable manufacturing/processing, etc., can solve the problems of high energy consumption, poor mass transfer and heat transfer, etc. quality, reducing nitrogen consumption, increasing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

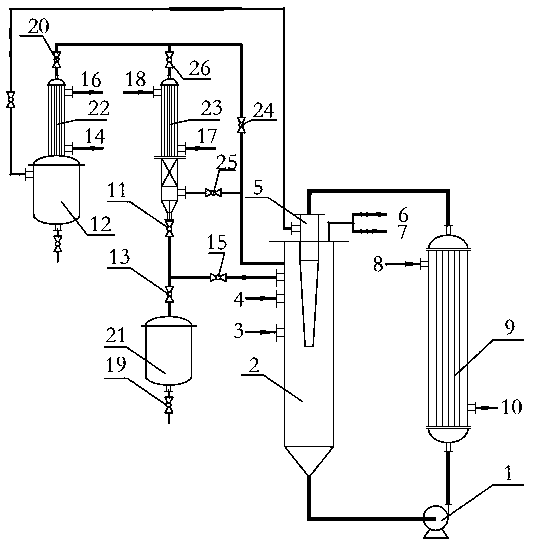

[0026] 40 kg of trimethyl tertiary amine and 61 kg of dimethyl carbonate were added to 200 L loop reactor 2, and the system was replaced with nitrogen 3 times to maintain the reaction pressure of the entire loop system at a nitrogen pressure of 0.01 MPa, and close the gas phase side Through the valve 24 and the gas phase inlet valve 25, the circulation pump 1 is turned on, and the loop circulation pump 1 sends it to the loop heat exchanger 9, and after being heated by the heat transfer oil, it reaches the Venturi reaction injector 5 at the top of the loop reactor 2 , enters the loop reactor 2 through injection to form a circulating flow, controls the injection flow rate to 10 m / s, and raises the temperature to 100 °C at the same time, at this time, the reaction pressure is 0.2 MPa. After reacting for 3.0 h, the loop is made When the reactor temperature drops to 95°C, the gas phase inlet valve 25 is opened, and the dimethyl carbonate vapor enters the condensation separation towe...

Embodiment 2

[0028] 50 kg of tributyl tertiary amine, 49 kg of dimethyl carbonate and 3.0 kg of methanol were added to the 200 L loop reactor 2, and the system was replaced with nitrogen to maintain the reaction pressure of the entire loop system at a nitrogen pressure of 0.01 MPa. Close the gas phase bypass valve 24 and the gas phase inlet valve 25, turn on the circulation pump 1, and transfer it to the loop heat exchanger 9 by the loop circulation pump 1, and reach the Venturi reaction at the top of the loop reactor 2 after being heated by the heat transfer oil. The injector 5 enters the loop reactor 2 through injection to form a circulating flow. The injection velocity is controlled to be 30 m / s, and the temperature is raised to 100 °C at the same time. At this time, the reaction pressure is 0.4 MPa. After 4.0 h of reaction, it passes through the external circulation heat exchanger 9 Make the loop reactor temperature drop to 95 DEG C, open the gas phase inlet valve 25, methanol and dimet...

Embodiment 3

[0030] Add 50 kg of dimethyloctyl tertiary amine, 113 kg of diethyl carbonate and 4.9 kg of methanol into the 200 L loop reactor 2, and replace the system with nitrogen to maintain the reaction pressure of the entire loop system at 0.01 MPa of nitrogen pressure, close the gas phase bypass valve 24 and the gas phase inlet valve 25, open the circulation pump 1, and transfer it to the loop heat exchanger 9 by the loop circulation pump 1, and reach the Venturi at the top of the loop reactor 2 after being heated by the heat transfer oil. The inner reaction injector 5 is injected into the loop reactor 2 to form a circulating flow. The injection flow rate is controlled to 40 m / s, and the temperature is raised to 140 ° C at the same time. At this time, the reaction pressure is 1.1 MPa. After 4.0 hours of reaction, the heat is exchanged through the external circulation Device 9 cools the loop reactor temperature to 130°C, opens gas phase inlet valve 25, methanol and diethyl carbonate va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com