Method for preparing high catalytic efficiency-type light-cured white solder-resist ink material

A technology of catalytic efficiency and solder resist ink, which is applied in ink, household utensils, applications, etc., can solve the problems of poor photocuring performance and easy yellowing of pure white ink, so as to improve exposure intensity and induction performance, and overcome curing Difficulty, reduce the effect of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

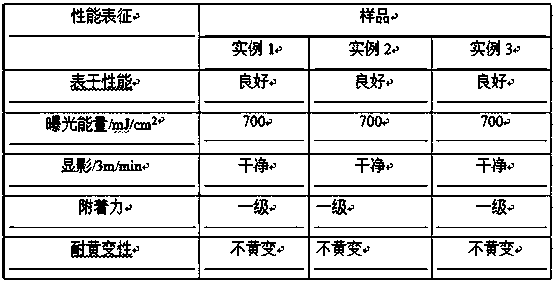

Examples

example 1

[0018] Take the red cabbage and wash, vacuum freeze-dry and grind through a 200-mesh sieve, collect the sieved powder and mix the sieved powder with 5mmol / L disodium hydrogen phosphate-sodium dihydrogen phosphate solution in a mass ratio of 1:10 The mixed solution was collected and placed in a homogenizer, homogenized and vacuum freeze-dried to obtain photosensitive protein particles; the gardenia petals were taken and washed and crushed, and the crushed petals were collected and counted in parts by weight, and 45 parts were weighed to remove Place ionized water, 55 parts of absolute ethanol, 1 part of glacial acetic acid and 10 parts of crushed petals in a three-necked flask, stir and mix and place it at 75°C for 20 hours, filter and collect the filtrate, and place the filtrate at 45°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a white pigment concentrate; in parts by weight, weigh 45 parts of UV resin UV2282, 10 parts of 200 mesh titanium dioxide, 3...

example 2

[0020] Take the red cabbage and wash, vacuum freeze-dry and grind through a 200-mesh sieve, collect the sieved powder and mix the sieved powder with 5mmol / L disodium hydrogen phosphate-sodium dihydrogen phosphate solution in a mass ratio of 1:10 The mixed solution was collected and placed in a homogenizer, homogenized and vacuum freeze-dried to obtain photosensitive protein particles; the gardenia petals were taken and washed and crushed, and the crushed petals were collected and counted in parts by weight, and 47 parts were weighed to remove Place ionic water, 57 parts of absolute ethanol, 1 part of glacial acetic acid and 12 parts of crushed petals in a three-necked flask, stir and mix and place it at 77°C for 22 hours, filter and collect the filtrate, and place the filtrate at 47°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a white pigment concentrate; in parts by weight, weigh 47 parts of UV resin UV2282, 12 parts of 200 mesh titanium dioxide, 4 p...

example 3

[0022] Take the red cabbage and wash, vacuum freeze-dry and grind through a 200-mesh sieve, collect the sieved powder and mix the sieved powder with 5mmol / L disodium hydrogen phosphate-sodium dihydrogen phosphate solution in a mass ratio of 1:10 The mixed solution was collected and placed in a homogenizer, homogenized and vacuum freeze-dried to obtain photosensitive protein particles; the gardenia petals were taken and washed and crushed, and the crushed petals were collected and counted in parts by weight, and 50 parts were weighed to remove Place ionized water, 60 parts of absolute ethanol, 2 parts of glacial acetic acid and 15 parts of crushed petals in a three-necked flask, stir and mix and place it at 80°C for 24 hours, filter and collect the filtrate, and place the filtrate at 50°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a white pigment concentrate; in parts by weight, weigh 50 parts of UV resin UV2282, 15 parts of 200 mesh titanium dioxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com