A wear-resistant Nd-Fe-B permanent magnet material for new energy vehicles and a preparation method thereof

A technology for new energy vehicles and permanent magnet materials, which is applied in the field of wear-resistant NdFeB permanent magnet materials and its preparation, and can solve problems such as high brittleness, impact resistance, and poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

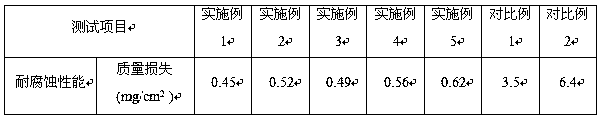

Examples

Embodiment 1

[0027] A method for preparing a wear-resistant NdFeB permanent magnet material for new energy vehicles, comprising the following steps:

[0028] S1. Grind kaolin into powder and pass through a 450-mesh sieve, bake at 75°C for 45 minutes, add pure water, stir at 90°C for 30 minutes, then add tributyl phosphate, cool to 70°C, Stir and mix for 2.5 hours, dry, and regrind to obtain modified kaolin powder; the mass ratio of the kaolin powder, purified water, and tributyl phosphate is 5:10:1;

[0029]S2. Sintering and cleaning the NdFeB magnetic material, placing it in the electrophoresis tank for cathodic electrophoresis coating treatment, the voltage is 70V, and the time is 10min; the bath liquid of the electrophoresis tank is made of polyurethane resin, silicone modified epoxy Resin, color glue, organic solvent and the colloidal solution configuration of the modified kaolin powder prepared in step S1 constitute; the mass ratio of the polyurethane resin, organosilicon modified epo...

Embodiment 2

[0033] A method for preparing a wear-resistant NdFeB permanent magnet material for new energy vehicles, comprising the following steps:

[0034] S1. Grind kaolin into powder and pass through a 420 mesh sieve, bake at 66°C for 30 minutes, add pure water, stir at 85°C for 20 minutes, then add tributyl phosphate, cool to 62°C, Stir and mix for 2 hours, dry, and regrind to obtain modified kaolin powder; the mass ratio of the kaolin powder, purified water, and tributyl phosphate is 5:10:1;

[0035] S2. Sintering and cleaning the NdFeB magnetic material, placing it in the electrophoresis tank for cathodic electrophoresis coating treatment, the voltage is 55V, and the time is 6min; the bath liquid of the electrophoresis tank is made of polyurethane resin, silicone modified epoxy Resin, color glue, organic solvent and the colloidal solution configuration of the modified kaolin powder prepared in step S1 constitute; the mass ratio of the polyurethane resin, organosilicon modified epoxy...

Embodiment 3

[0039] A method for preparing a wear-resistant NdFeB permanent magnet material for new energy vehicles, comprising the following steps:

[0040] S1. Grind kaolin into powder and pass through a 500-mesh sieve, bake at 85°C for 50 minutes, add pure water, stir at 90°C for 35 minutes, then add tributyl phosphate, cool to 75°C, Stir and mix for 2.5 hours, dry, and regrind to obtain modified kaolin powder; the mass ratio of the kaolin powder, purified water, and tributyl phosphate is 5:10:1;

[0041] S2. Sintering and cleaning the NdFeB magnetic material, placing it in the electrophoresis tank for cathodic electrophoresis coating treatment, the voltage is 80V, and the time is 15min; the bath liquid of the electrophoresis tank is made of polyurethane resin, silicone modified epoxy Resin, color glue, organic solvent and the colloidal solution configuration of the modified kaolin powder prepared in step S1 constitute; the mass ratio of the polyurethane resin, organosilicon modified ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com