Algae oil DHA liquid beverage and preparation method thereof

A technology of algae oil and liquid, which is applied in the field of algae oil DHA liquid beverage and its preparation, which can solve the problems of sinking and oxidation, reducing the retention rate of DHA, splitting reaction, etc., so as to improve stability and reduce theophylline and tea tannin Composition, effect of extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

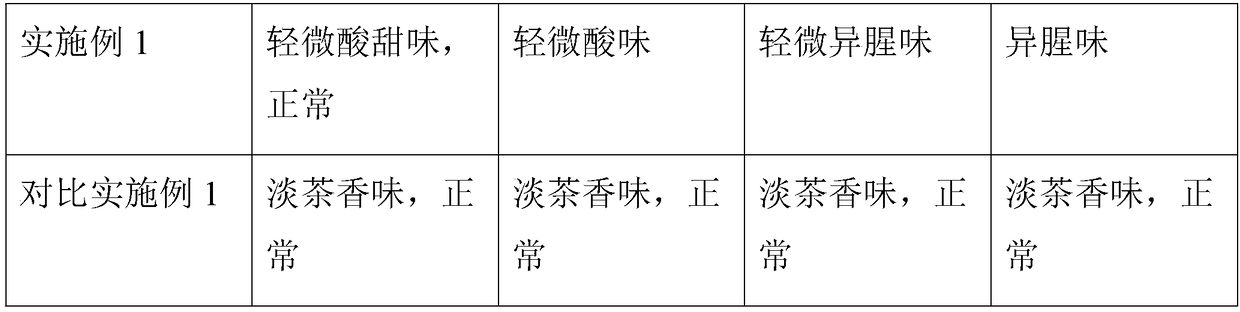

Embodiment 1

[0019] Embodiment 1: the preparation of algae oil DHA liquid beverage

[0020] (1) Measure each raw material respectively according to the following formula: algae oil DHA preparation: microcapsule powder DHA100g, microemulsion DHA250ml; green tea 9kg; bioflavonoids 80g; vitamin C100g; food additives: white granulated sugar 250g, sodium benzoate 100g, sodium citrate 150g, sodium alginate 100g; deionized water 90L;

[0021] (2) Soak green tea in deionized water at room temperature, stir for 2 hours at 100r / min, and then use a molecular weight cut-off range of 5×10 4 , the transmembrane pressure is 1kg / cm 2 The hollow fiber ultrafiltration membrane is used to filter the leachate and collect the filtrate;

[0022] (3) Add algae oil DHA preparation, vitamin C and bioflavonoids to the filtrate in turn, shear and mix, and after standing at 35°C for 20 minutes, add food additives, shear and mix;

[0023] (4) Carry out clarification filtration with beverage filter first, obtain fin...

Embodiment 2

[0024] Embodiment 2: the preparation of algae oil DHA liquid beverage

[0025] Adopt the preparation method of embodiment 1, difference is: raw material formula is as follows: algae oil DHA preparation: microemulsion DHA 150ml, DHA algae oil 100ml; Green tea 10kg; Bioflavonoid 150g; Vitamin C80g; Food additive: honey 100g, sodium benzoate 150g, citric acid 100g, xanthan gum 200g; deionized water 89L.

Embodiment 3

[0026] Embodiment 3: the preparation of algae oil DHA liquid beverage

[0027] Adopt the preparation method of embodiment 1, difference is: raw material formula is as follows: algae oil DHA preparation: microcapsule powder DHA200g; Green tea 12kg; Bioflavonoid 300g; Vitamin C200g; acid 80g, sodium citrate 80g, guar gum 250g, deionized water 87L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com