Water-based damping coating for automobiles

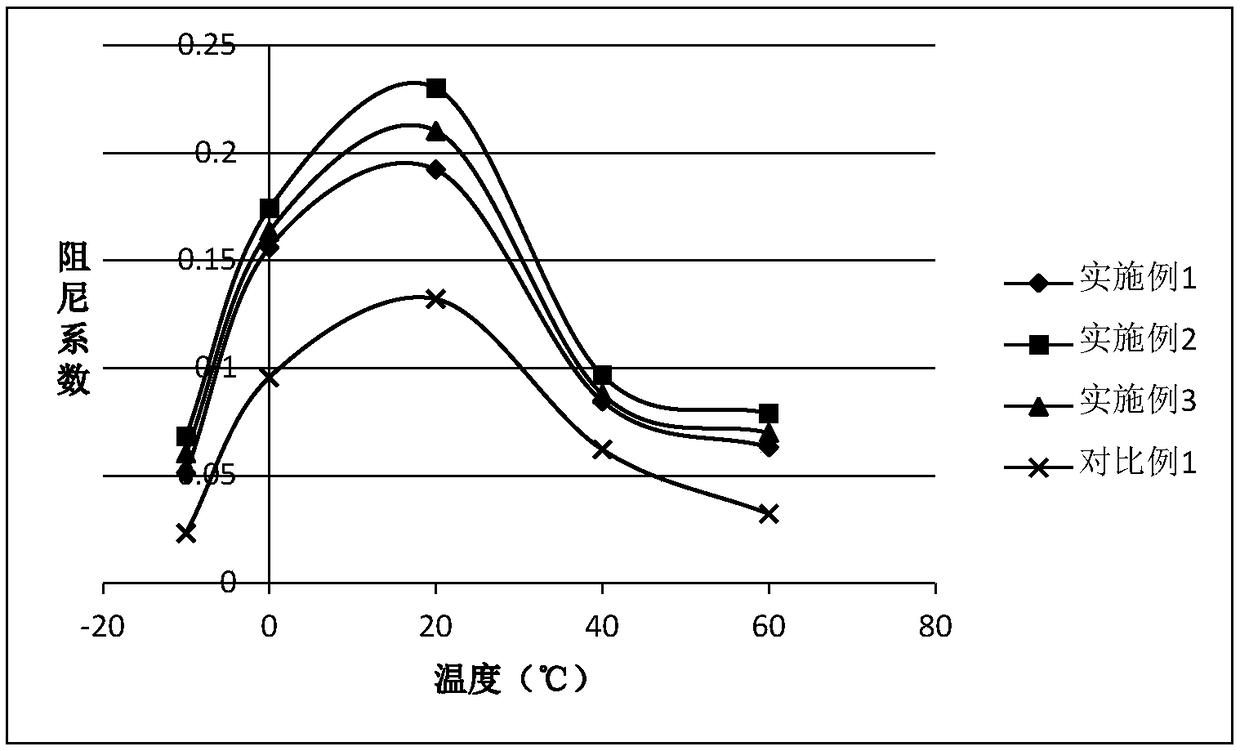

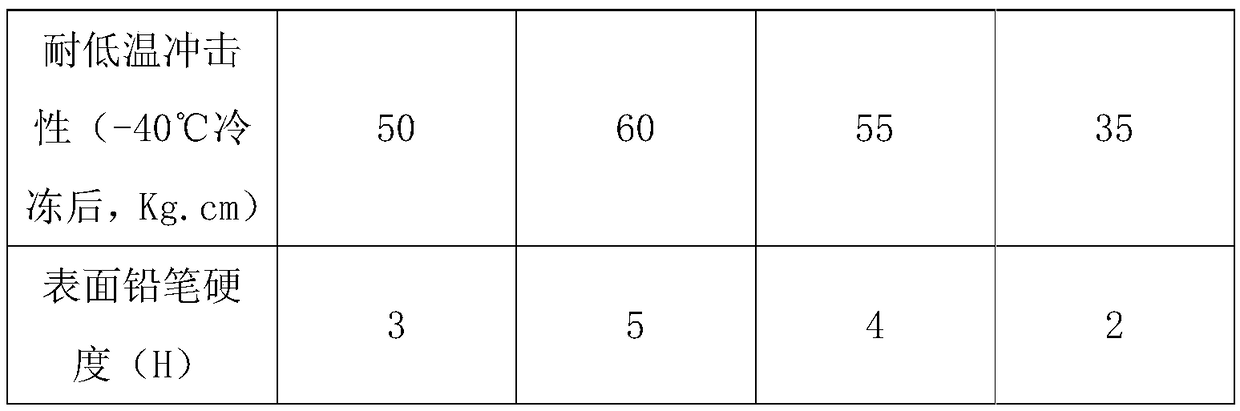

A damping paint, water-based technology, applied in the field of automobile damping and shock absorption, to achieve the effect of enhancing the damping coefficient, increasing the ductility, and enhancing the hardness of the pencil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A water-based damping coating for automobiles, consisting of the following raw materials in parts by weight: 40 parts of water-based emulsion, 12 parts of plant fiber, 6 parts of graphite, 30 parts of calcium carbonate, 3 parts of dispersant, 4 parts of defoamer, 18 parts of water share.

[0025] The aqueous emulsion is a mixture of pure acrylic emulsion, styrene-butadiene emulsion, and styrene-acrylic emulsion according to the mass and number ratio of 1:1.5:1, the plant fiber is a fern plant fiber, and the dispersant is calcium stearate, The defoamer is silicone oil.

[0026] The detected volatile organic compound content was 112.5g / l and the free formaldehyde content was 8mg / kg. All meet environmental protection standards.

Embodiment 2

[0028] A water-based damping paint for automobiles, consisting of the following raw materials in parts by weight: 60 parts of water-based emulsion, 20 parts of plant fiber, 14 parts of graphite, 40 parts of calcium carbonate, 5 parts of dispersant, 7 parts of defoamer, 26 parts of water share.

[0029] The aqueous emulsion is a mixture of pure acrylic emulsion, styrene-butadiene emulsion, and styrene-acrylic emulsion according to the mass and number ratio of 1:1.5:1, the plant fiber is a fern plant fiber, and the dispersant is calcium stearate, The defoamer is silicone oil.

[0030] The detected volatile organic compound content was 112.5g / l and the free formaldehyde content was 8mg / kg. All meet environmental protection standards.

Embodiment 3

[0032] A water-based damping coating for automobiles, consisting of the following raw materials in parts by weight: 50 parts of water-based emulsion, 16 parts of plant fiber, 10 parts of graphite, 35 parts of calcium carbonate, 4 parts of dispersant, 5 parts of defoamer, 22 parts of water share.

[0033] The aqueous emulsion is a mixture of pure acrylic emulsion, styrene-butadiene emulsion, and styrene-acrylic emulsion according to the mass and number ratio of 1:1.5:1, the plant fiber is a fern plant fiber, and the dispersant is calcium stearate, The defoamer is silicone oil.

[0034] The detected volatile organic compound content was 112.5g / l and the free formaldehyde content was 8mg / kg. All meet environmental protection standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com