Peanut coat oligomeric proanthocyanidin, preparation method and application thereof

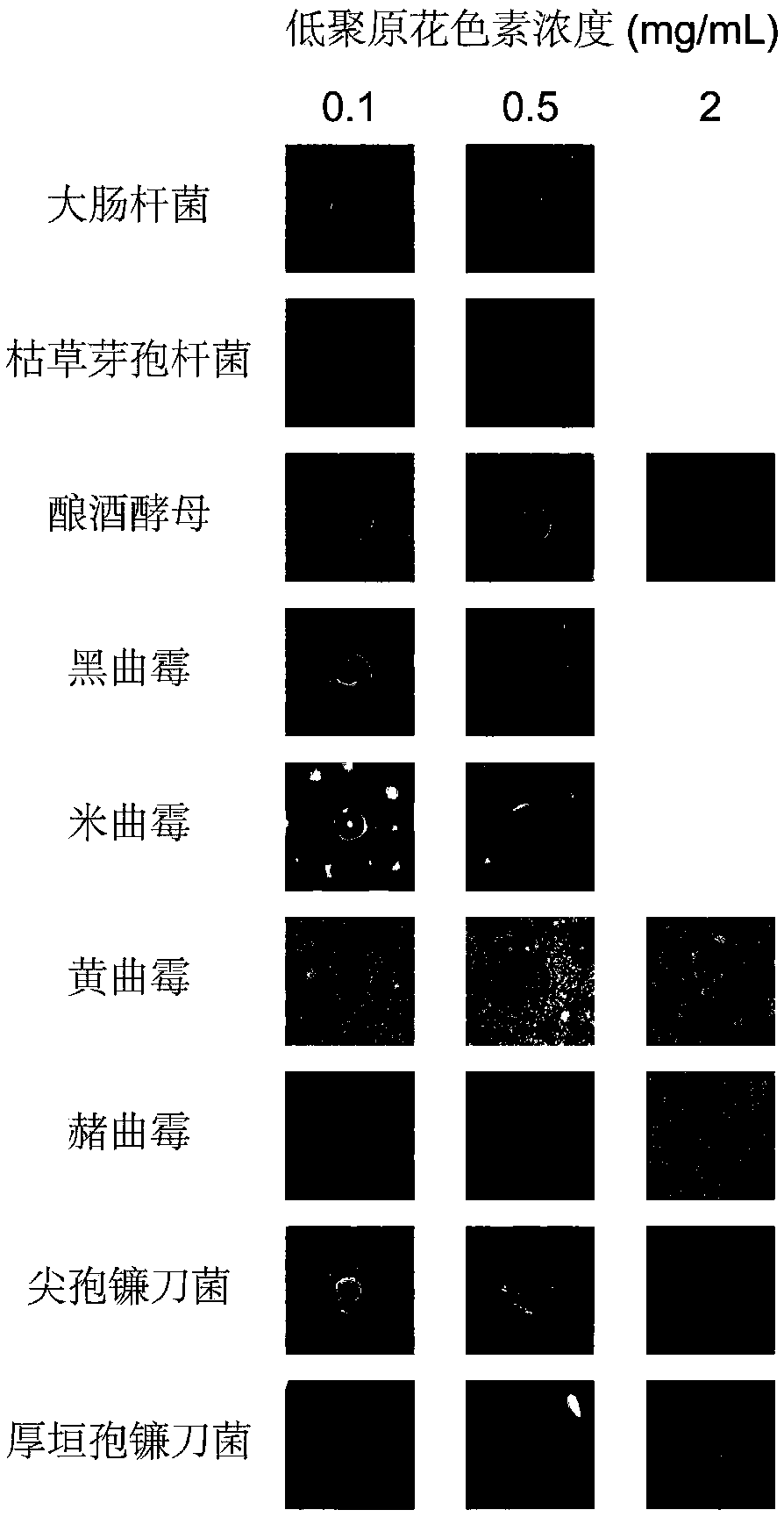

A technology of oligomeric proanthocyanidins and peanut coating, applied in biochemical equipment and methods, microorganism-based methods, microorganisms and other directions, can solve the problems of the destruction of the activity of monomer proanthocyanidins, the degree of degradation is not easy to control, etc., to improve the synergy Fermentation performance, high active ingredients, antioxidant activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Saccharomyces cerevisiae suspension: Take the bacterial solution preserved in 20% glycerol at -80°C, inoculate it in YPD liquid medium with 1% inoculum, and cultivate it in a shaker at 30°C with a rotation speed of 160r / min for 24h. The number of live bacteria of Saccharomyces cerevisiae in the fermentation liquid was 5.5×10 8-9 CFU / mL.

[0033] Preparation of Bacillus subtilis bacterial suspension: Take the bacterial solution preserved in 20% glycerol at -80°C, inoculate it in LB liquid medium with 1% inoculum, cultivate it in a shaker at 35°C with a rotation speed of 180r / min for 12h, At this time, the number of live bacteria of Bacillus subtilis in the fermentation broth was 1.1×10 10-12 CFU / mL.

[0034] After the peanut shells are washed, dried and crushed, they are mixed with water at a mass volume ratio of 1:40, and the bacterial liquids of Saccharomyces cerevisiae and Bacillus subtilis are added sequentially according to the inoculum amount (v / v)...

Embodiment 2

[0049] Preparation of Saccharomyces cerevisiae suspension: Take the bacterial solution preserved in 20% glycerol at -80°C, inoculate it in YPD liquid medium with 1% inoculum, and cultivate it in a shaker at 30°C with a rotation speed of 160r / min for 24h. The number of live bacteria of Saccharomyces cerevisiae in the fermentation liquid was 5.5×10 8-9 CFU / mL.

[0050] Aspergillus niger (Aspergillus niger) culture: Stretch culture on PDA solid slant medium, culture temperature 28°C, culture time 2-3 days. Wash the spore powder on the surface of the medium with sterilized deionized water to make a spore content of 10 6 The spore suspension per mL was used for inoculation.

[0051] After washing, drying, and pulverizing the peanut shells, mix them with water at a mass-volume ratio of 1:40, and add the bacterial liquids of Saccharomyces cerevisiae and Aspergillus niger according to the inoculum amounts (v / v) of 7% and 3% in turn, and the inoculated The peanut shell mixture was f...

Embodiment 3

[0054] Preparation of Saccharomyces cerevisiae suspension: Take the bacterial solution preserved in 20% glycerol at -80°C, inoculate it in YPD liquid medium with 1% inoculum, and cultivate it in a shaker at 30°C with a rotation speed of 160r / min for 24h. The number of live bacteria of Saccharomyces cerevisiae in the fermentation liquid was 5.5×10 8-9 CFU / mL.

[0055] Cultivation of Aspergillus oryzae: Stretch culture on PDA solid slant medium, culture temperature 30° C., culture time 2-3 days. Wash the spore powder on the surface of the medium with sterilized deionized water to make a spore content of 10 6 The spore suspension per mL was used for inoculation.

[0056] Cleaning of peanut shells, after washing, drying, and crushing, the peanut shells are mixed with water at a mass volume ratio of 1:40, and the bacterial liquids of Saccharomyces cerevisiae and Aspergillus oryzae are added according to the inoculum amount (v / v) of 7% and 4% in turn , the inoculated peanut shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com