Online pan head reinforcement production method for spunbonded needle-punched nonwoven fabric

A technology of spunbonded nonwoven fabrics and nonwoven fabrics, applied in the field of spunbonded needle-punched nonwovens on-line pan-head reinforcement production, which can solve the problems of long production process, waste of manpower and power resources, complicated production operations, etc., and achieve Improve product performance, increase tear strength, and improve dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

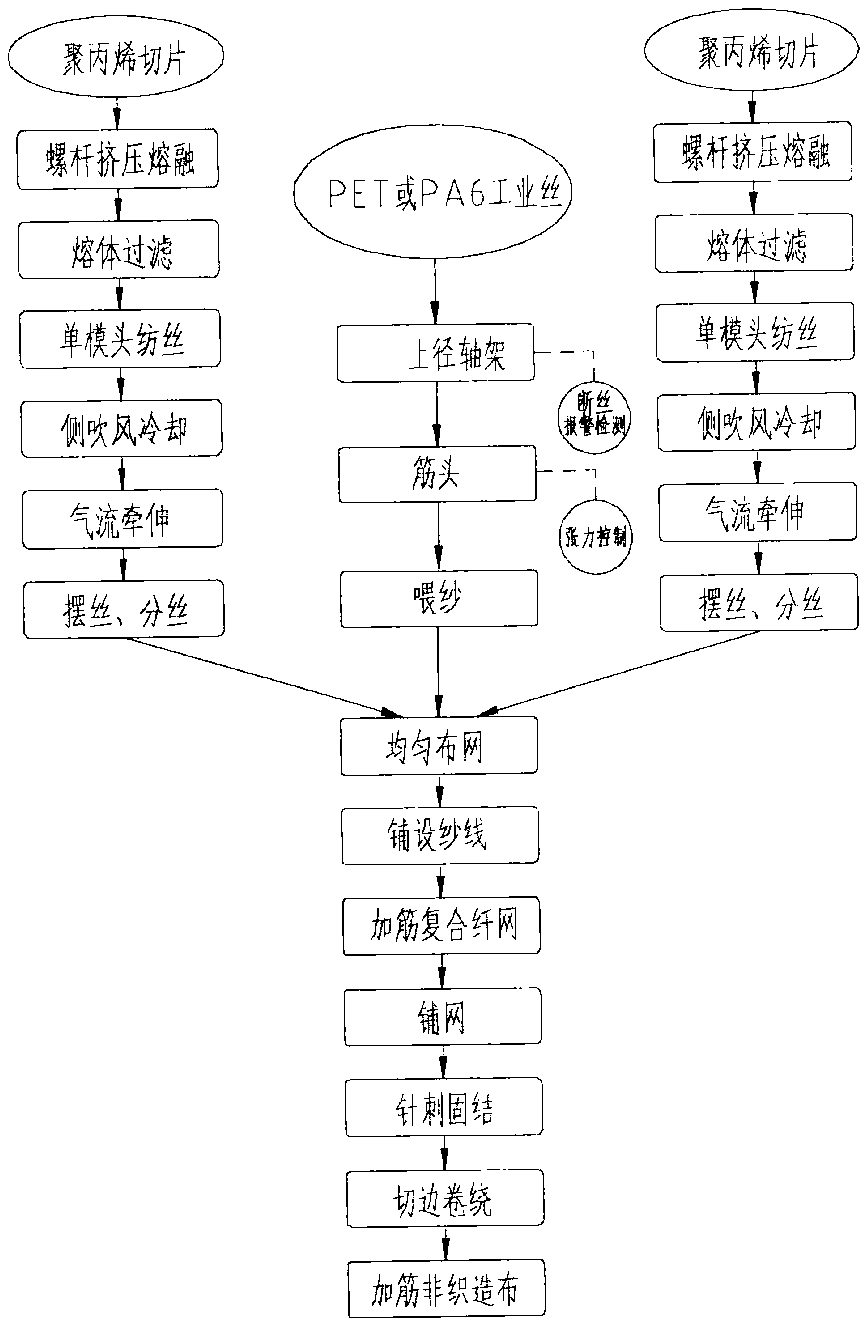

[0058] figure 1 As shown in the schematic diagram of the present invention, the production process of adding reinforcing materials on-line on a polypropylene spunbonded nonwoven production line.

[0059] The weight is 200g / m 2 The production steps of polypropylene spunbond filament nonwoven web are as follows:

[0060] 1. Steps for spunbonded nonwoven fabric with polypropylene as raw material:

[0061] (1) Material preparation: use polypropylene chips as raw materials, with a melting point of 165°C;

[0062] (2) Screw extrusion melting: The polypropylene raw material enters the corresponding screw extruder and extrudes into a molten state. The heating temperature of each heating zone of the screw extruder is 162℃, 202℃, 222℃, 242℃, 252 ℃, 262℃;

[0063] (3) Melt filtration: the polypropylene melt is filtered through a melt filter, and the pressure after the filter is 10Mpa;

[0064] (4) Single-die spinning: After filtering, it enters the single-die spinning box, quantitatively squeezed ...

Embodiment 2

[0084] figure 1 As shown in the schematic diagram of the present invention, the production process of adding reinforcing materials on-line on a polypropylene spunbonded nonwoven production line.

[0085] The gram weight is 100g / m 2 The production steps of polypropylene spunbond filament nonwoven web are as follows:

[0086] 1. Steps for spunbonded nonwoven fabric with polypropylene as raw material:

[0087] (1) Material preparation: use polypropylene chips as raw materials, with a melting point of 165°C;

[0088] (2) Screw extrusion melting: The polypropylene raw material enters the corresponding screw extruder and extrudes into a molten state. The heating temperature of each heating zone of the screw extruder is 160℃, 200℃, 220℃, 2402℃, 250 ℃, 260℃;

[0089] (3) Melt filtration: the polypropylene melt is filtered through a melt filter, and the pressure after the filter is 7Mpa;

[0090] (4) Single-die spinning: After filtering, it enters the single-die spinning box, quantitatively sque...

Embodiment 3

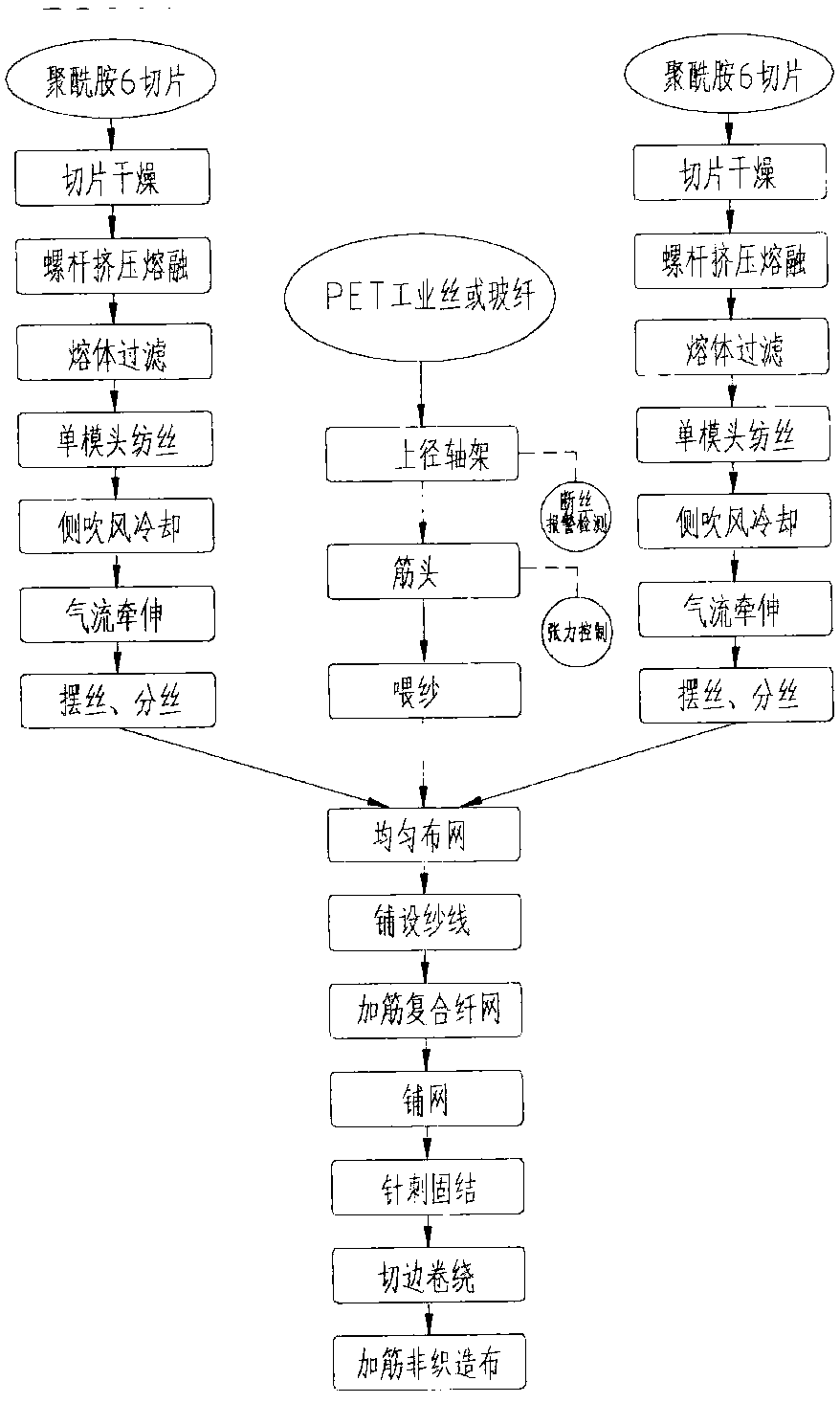

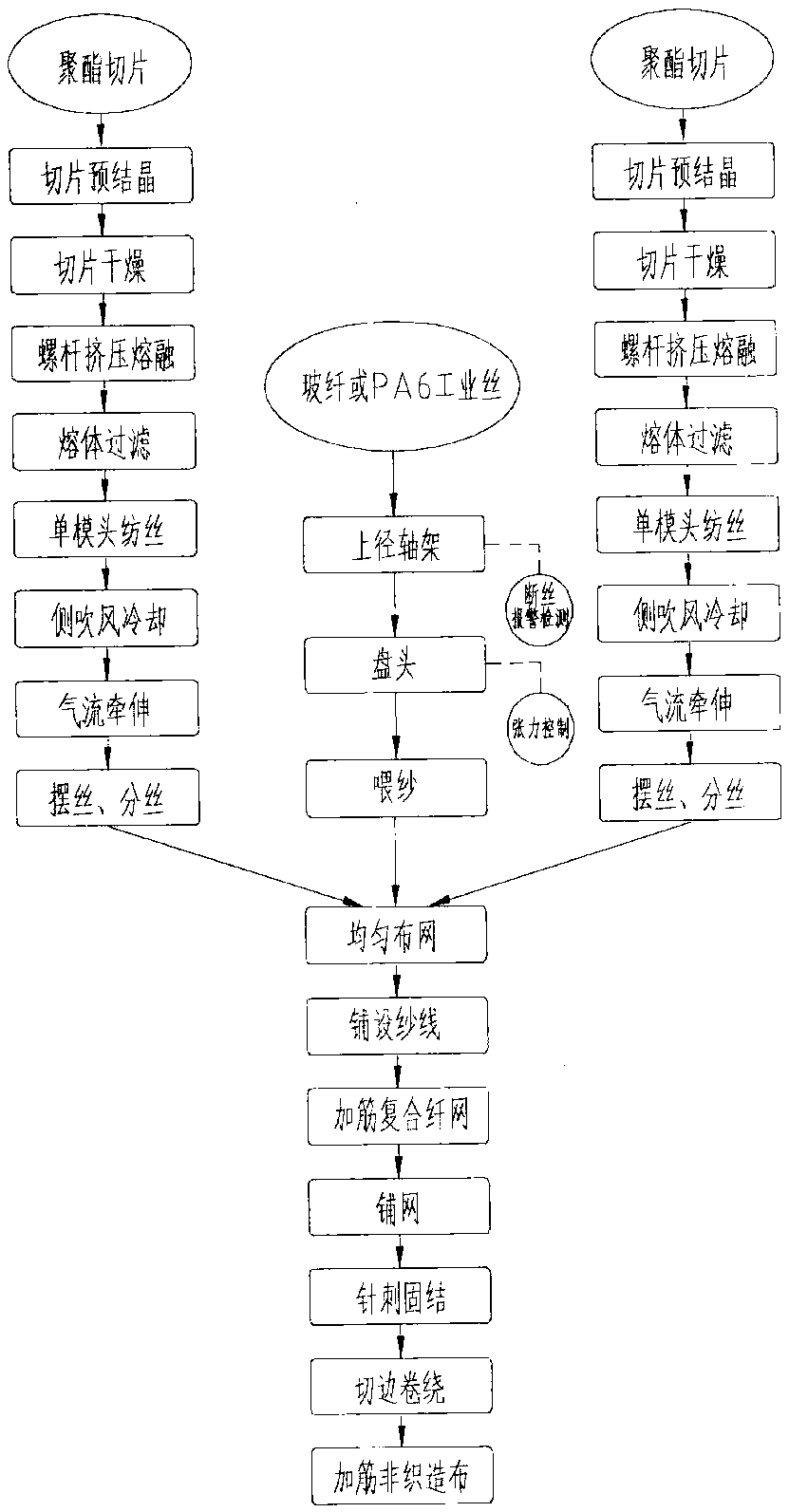

[0110] figure 2 As shown in the schematic diagram of the present invention, the production process of adding reinforcing materials on-line on a polyester spunbonded nonwoven production line.

[0111] The weight is 200g / m 2 The production steps of polyester spunbond filament nonwoven web are as follows:

[0112] 1. Steps of spunbonded nonwoven fabric with polyester chips as raw material:

[0113] (1) Material preparation: use polyester chips as raw materials, with a melting point of 260°C;

[0114] (2) Chip pre-crystallization: The polyester chips are transported into the pre-crystallizer respectively for crystallization, the crystallization temperature is 165°C, and the crystallization time is 20 minutes;

[0115] (3) Chip drying: Fall into the corresponding drying tower by its own weight, the drying temperature is 170℃, the drying time is 6 hours, and the water content of the polyester dry chips is 30ppm;

[0116] (4) Screw extrusion melting: the polyester raw materials enter the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com