Preparation method for internal-expansion nanoporous thermal-insulation material

A technology of thermal insulation materials and nanopores, which is applied in plastic recycling, artificial filaments made of inorganic raw materials, textiles and papermaking, etc., can solve the problems of high temperature shrinkage, low strength, and low safety factor of thermal insulation materials, and achieve improved heat dissipation area, High thermal conductivity and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

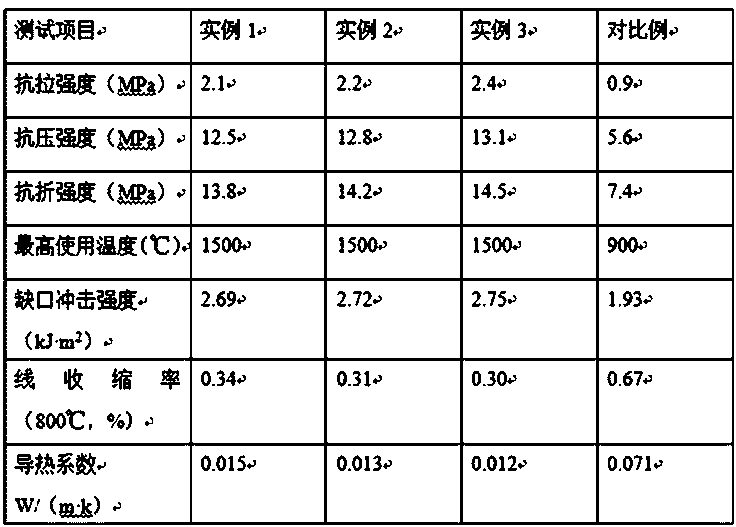

example 1

[0026] In parts by weight, add 70 parts of kaolin, 20 parts of alumina, 10 parts of titanium dioxide, and 20 parts of aluminum phosphate to 400 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 5, heat up to 50°C, and keep it warm for 10 hours to obtain a mixed slurry; grind the bentonite and pass it through a 400-mesh sieve, and then calcinate at a high temperature of 600°C for 2 hours to obtain light-burned bentonite. Soil, 10 parts of light-burned bentonite were mixed through a 400-mesh sieve to obtain mixed clay, and 35 parts of nano-silica airgel, 30 parts of the above-mentioned mixed clay, and 200 parts of water were mixed to obtain nano-silica airgel slurry; The slurry and the nano-silica airgel slurry are mixed at a volume ratio of 4:1, heated to 700°C to obtain a molten feed solution, and modified aluminum silicate fibers a...

example 2

[0028] In parts by weight, add 75 parts of kaolin, 25 parts of alumina, 13 parts of titanium dioxide, and 21 parts of aluminum phosphate to 450 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 5, heat it up to 55°C, and keep it warm for 13 hours to obtain a mixed slurry; grind the bentonite and pass it through a 400-mesh sieve, and then calcinate at a high temperature of 700°C for 3 hours to obtain light-burned bentonite. 25 parts of diatoms Soil, 13 parts of light-burned bentonites were mixed through a 400-mesh sieve to obtain mixed clay, and 47 parts of nano-silica airgel, 35 parts of the above-mentioned mixed clay, and 250 parts of water were mixed to obtain nano-silica airgel slurry; The slurry and the nano-silica airgel slurry are mixed at a volume ratio of 4:1, heated to 750°C to obtain a molten material liquid, and modified ...

example 3

[0030] In parts by weight, add 80 parts of kaolin, 30 parts of alumina, 15 parts of titanium dioxide, and 22 parts of aluminum phosphate to 500 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 6, heat up to 60°C, and keep it warm for 15 hours to obtain a mixed slurry; grind the bentonite and pass it through a 400-mesh sieve, and then calcinate at a high temperature of 800°C for 4 hours to obtain light-burned bentonite. Soil, 15 parts of light-burned bentonite were mixed through a 400-mesh sieve to obtain mixed clay, and 50 parts of nano-silica airgel, 40 parts of the above-mentioned mixed clay, and 300 parts of water were mixed to obtain nano-silica airgel slurry; The slurry and the nano-silica airgel slurry are mixed at a volume ratio of 4:1, heated to 800°C to obtain a molten material liquid, and modified aluminum silicate fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com