An in-situ passivation insulation coating treatment method of a metal soft magnetic composite material

A composite material and insulating coating technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of low bonding strength of insulating film and uneven coating layer, and achieve large-scale industrial production, low preparation cost and strong bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

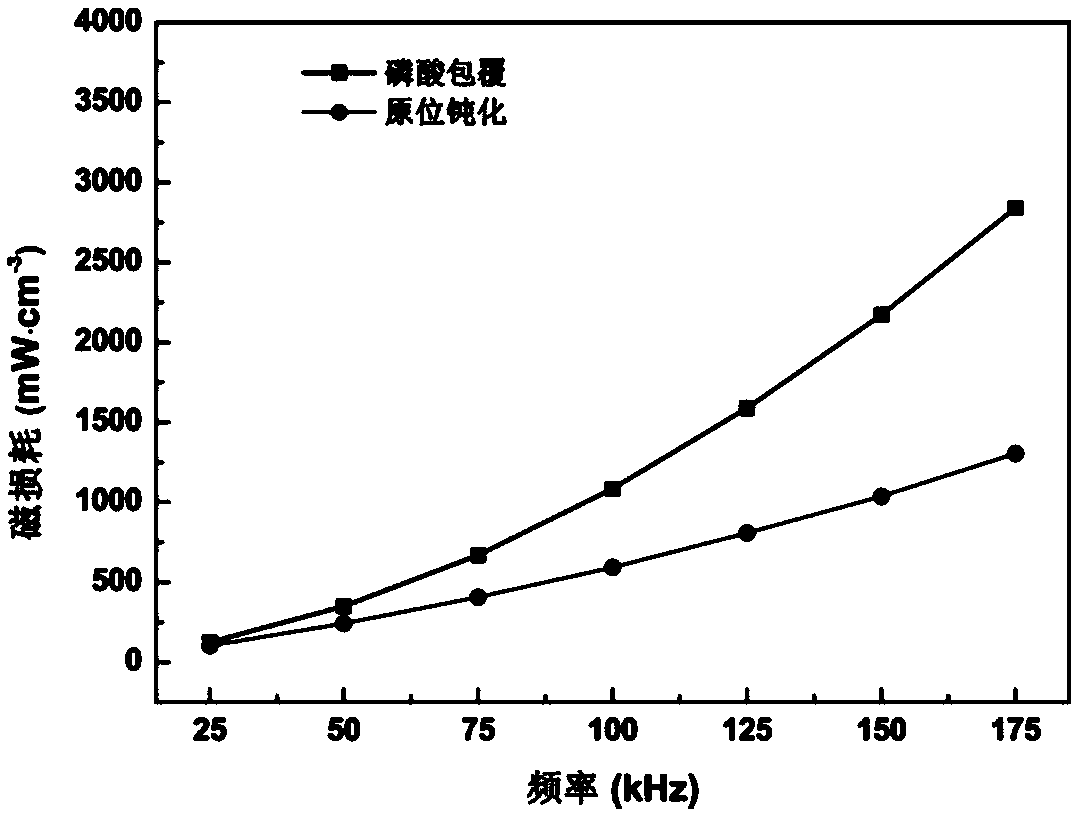

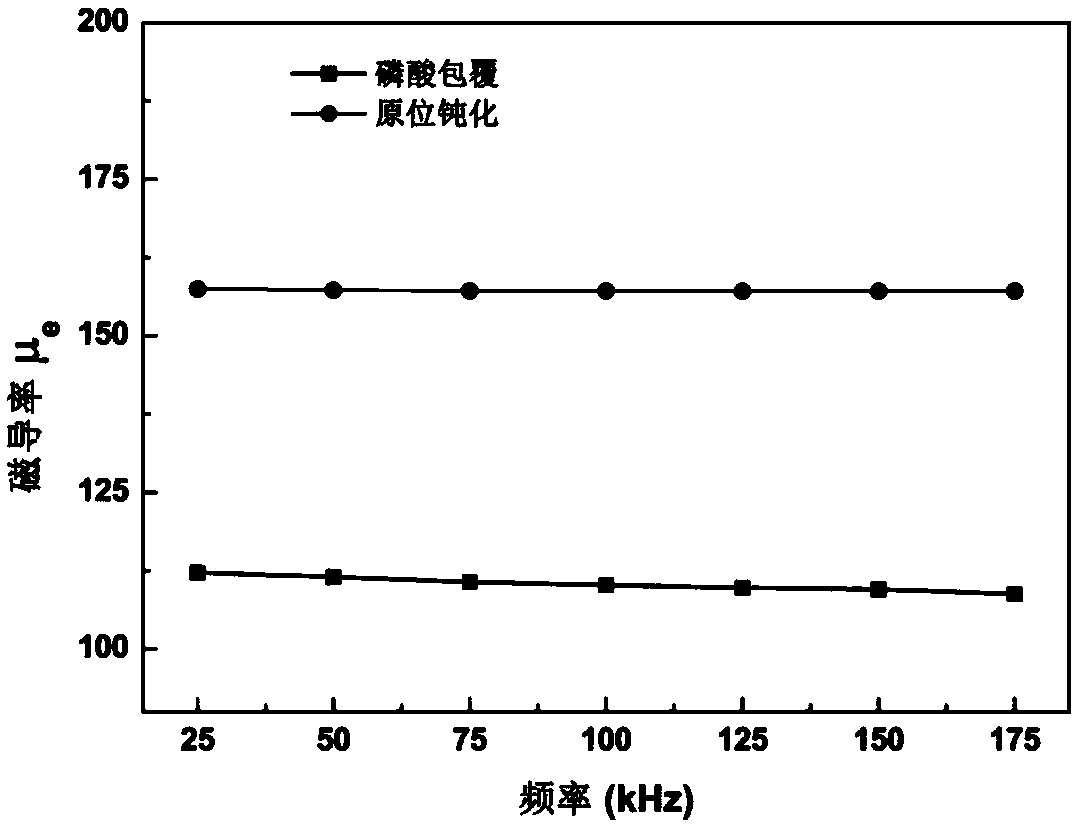

Embodiment 1

[0022] Add 6 g of concentrated sulfuric acid to 30 g of absolute ethanol and stir for 15 min to obtain a passivation solution. After sieving 15 g of iron powder for particle size ratio, add it to the passivation solution, stir evenly for 20 min, then filter and dry to obtain passivated magnetic powder. Add a binder accounting for 1.0% of the mass of the passivated magnetic powder into the passivated magnetic powder, and stir fully under heating conditions until the mixture is dry and uniformly mixed, and the binder is epoxy resin. Finally, in the passivated magnetic powder, add a release agent accounting for 0.5% of the total weight of the passivated magnetic powder and mix evenly. The release agent is zinc stearate to obtain the magnetic powder to be formed. The magnetic powder to be molded was pressed under a pressure of 800 MPa to form an annular soft magnetic composite material with an outer diameter of 23.4 mm, an inner diameter of 14.4 mm, and a height of 8.8 mm. Nitroge...

Embodiment 2

[0030] Add 5 g of concentrated nitric acid into 25 g of absolute ethanol and stir for 20 min to obtain a passivation solution. Sieve 10 g of sendust powder for particle size ratio, add it into the passivation solution, and stir evenly for 10 min, then filter and dry to obtain passivated magnetic powder. Add a binder accounting for 0.5% of the mass of the passivated magnetic powder into the passivated magnetic powder, and stir fully under heating conditions until the mixture is dry and uniformly mixed, and the binder is a phenolic resin. Finally, in the passivated magnetic powder, add a release agent accounting for 1.0% of the total weight of the passivated magnetic powder and mix evenly. The release agent is calcium stearate to obtain the magnetic powder to be formed. The magnetic powder to be molded was pressed under a pressure of 1800 MPa to form an annular soft magnetic composite material with an outer diameter of 23.4 mm, an inner diameter of 14.4 mm, and a height of 8.8 m...

Embodiment 3

[0038] Add 10 g of concentrated nitrous acid into 40 g of absolute ethanol and stir for 10 min to obtain a passivation solution. After sieving 20 g of iron-nickel powder for particle size ratio, add it to the passivation solution, stir evenly for 15 minutes, then filter and dry to obtain passivated magnetic powder. Add a binder accounting for 1.5% of the mass of the passivated magnetic powder into the passivated magnetic powder, and stir fully under heating conditions until the mixture is dry and uniformly mixed, and the binder is silicone resin. Finally, in the passivated magnetic powder, add a release agent accounting for 0.5% of the total weight of the passivated magnetic powder and mix evenly. The release agent is barium stearate to obtain the magnetic powder to be formed. The magnetic powder to be molded is pressed under a pressure of 1400 MPa to form an annular soft magnetic composite material with an outer diameter of 23.4 mm, an inner diameter of 14.4 mm, and a height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inductance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com