Flip-chip structure micro-size photonic crystal LED array chip and preparation method thereof

An LED array and photonic crystal technology, which is applied in the field of flip-chip micro-size photonic crystal LED array chips and their preparation, can solve problems such as poor ohmic contact performance, and achieve improved recombination rate, improved luminous efficiency and modulation bandwidth, and improved output. The effect of optical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

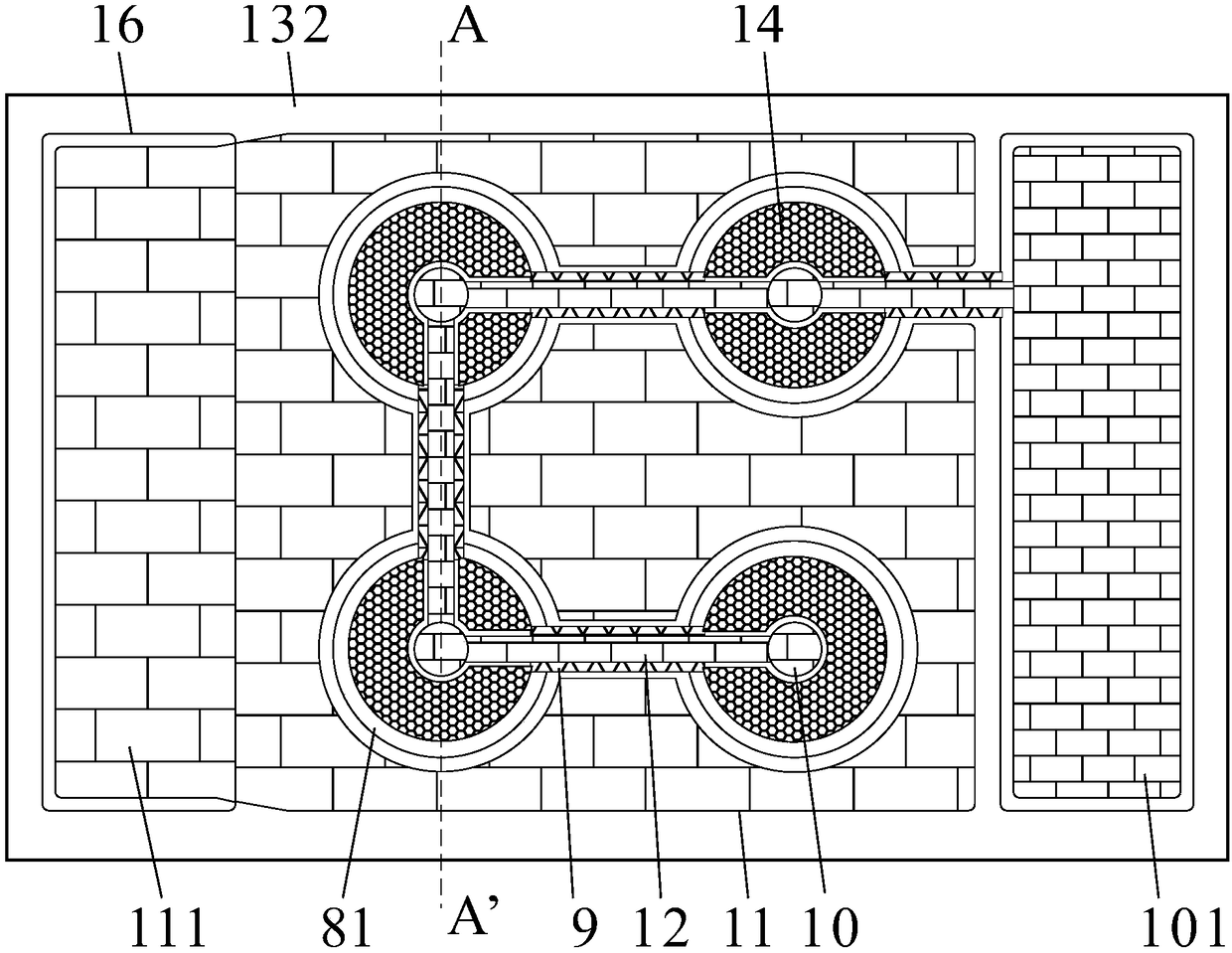

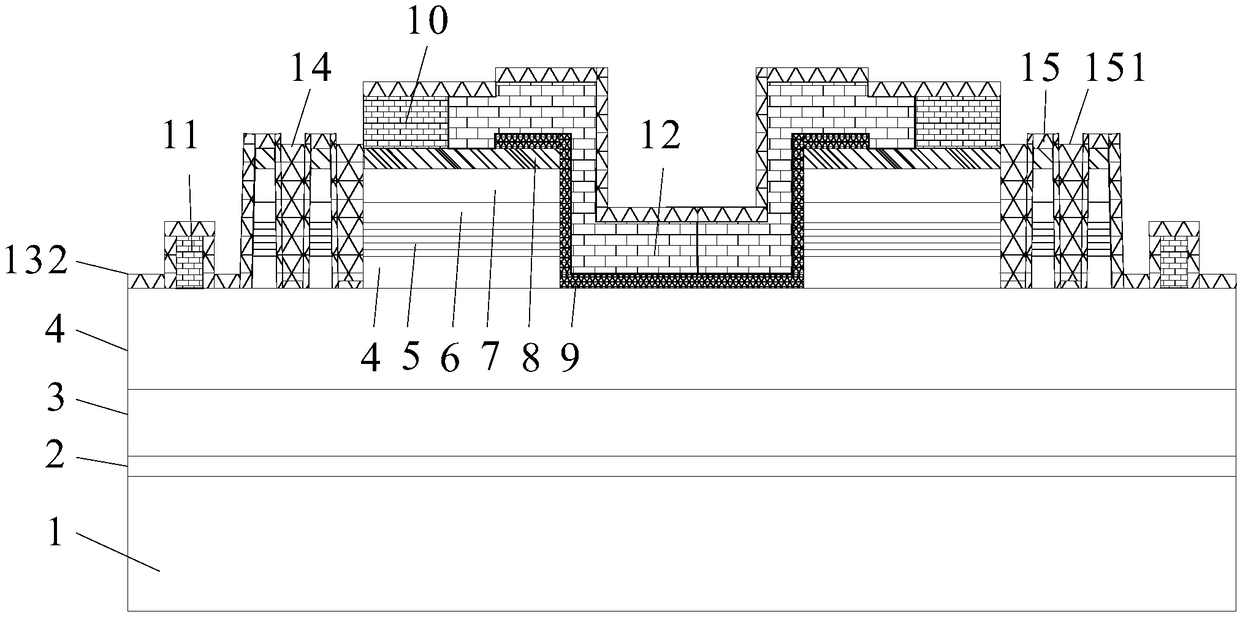

[0052] Embodiment 1, the preparation steps of the flip-chip micro-sized photonic crystal LED array chip are as follows.

[0053] (1) GaN-based LED epitaxial wafers are prepared by metal oxide vapor deposition. The structure of GaN-based LED epitaxial wafers includes sapphire substrate 1, GaN buffer layer 2, unintentionally doped GaN layer 3, and N-type doped GaN layer. 4. Quantum well layer 5 , P-type doped AlGaN layer 6 and P-type doped GaN layer 7 .

[0054] (2) Deposit a transparent current spreading layer ITO 8 with a thickness of 100 nm on the GaN-based LED epitaxial wafer using electron beam evaporation, in N 2 200sccm, O 2 Rapid annealing in a mixed atmosphere of 35 sccm for 3 minutes to form an ohmic contact, and then use ultraviolet lithography and wet etching, and soak in ITO etching solution for 15 minutes at room temperature to form an ITO disc 8 distributed only in the active area of the light-emitting unit. 98 μm in diameter.

[0055] (3) Etching by induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com