A construction method of functional graphite felt and its application in vanadium battery

A construction method and technology of graphite felt, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve the problems of decreased electrical conductivity, limited improvement of electrochemical performance, weakened positive effect of electrochemical activity, etc. Electrochemical and electrochemical polarization, low cost, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

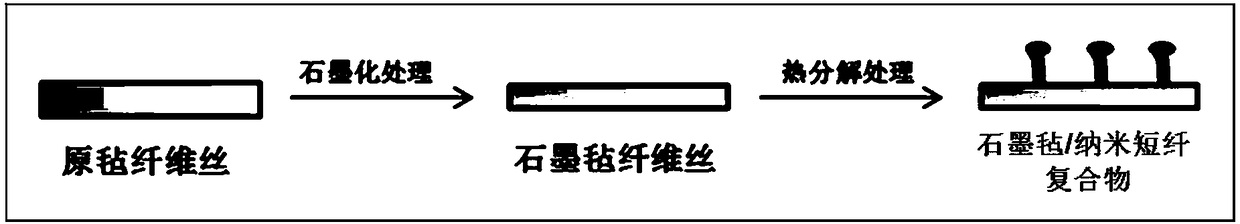

[0036] In the present embodiment, the polyacrylonitrile-based raw felt is placed in a graphitization furnace, under N 2 Graphitization treatment is carried out in the atmosphere, wherein the treatment temperature is 2300 °C, and the treatment time is 3 hours, and graphite felt with excellent conductivity can be obtained; the above-mentioned graphite felt is directly placed in the mixed gas of methane and hydrogen by pyrolysis method to realize carbon nanotubes 1. Chemical deposition of nanofibers on graphite felt fibers, wherein the molar ratio of methane and hydrogen is 1:10, the decomposition temperature is 800°C, and the deposition time is 1h; finally graphite felt / nano short fiber functional composite electrodes can be obtained.

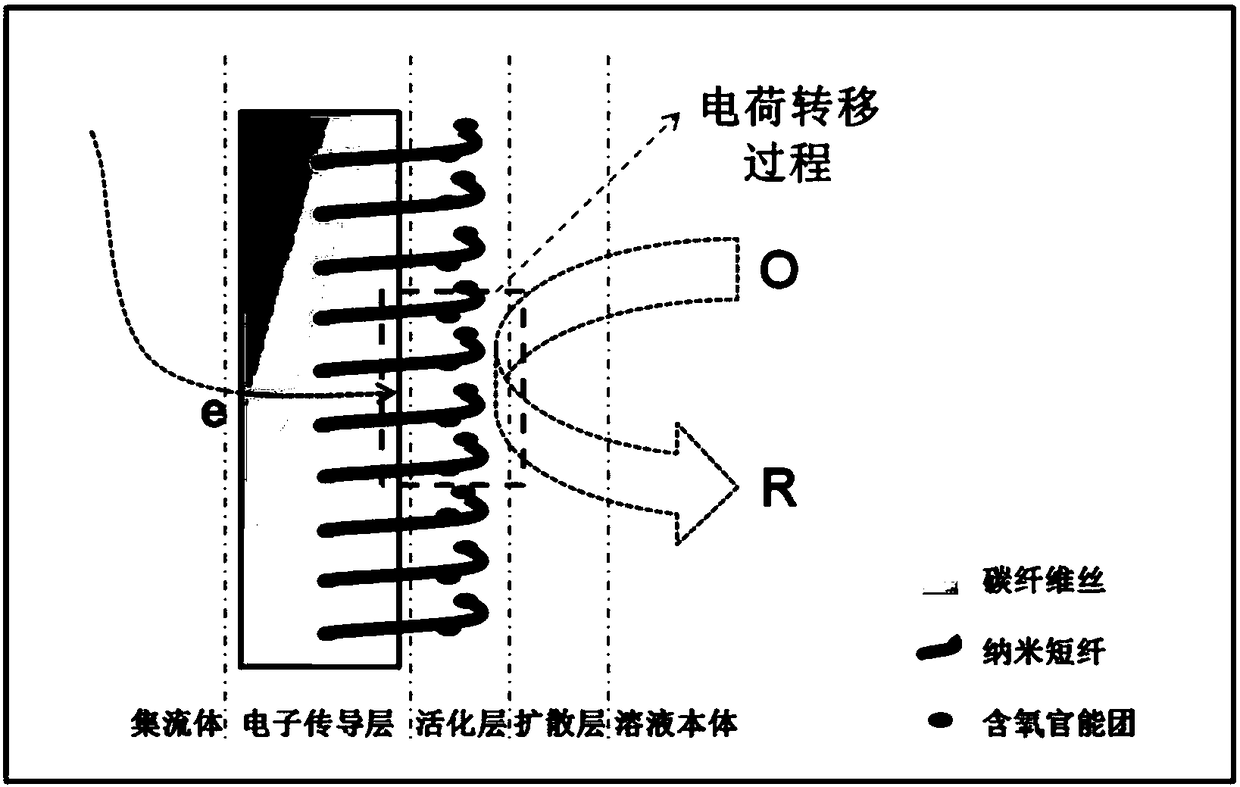

[0037] Through physical characterization, it is found that a large number of carbon nanotubes or carbon nanofibers grow on the surface of the carbon fiber of the composite electrode, the diameter of which is about 100-200nm, and its conductivity i...

Embodiment 2

[0039] In the present embodiment, the polyacrylonitrile-based raw felt is placed in a graphitization furnace, under N 2 Graphitization treatment is carried out in the atmosphere, wherein the treatment temperature is 2500 ° C, and the treatment time is 3 hours, and graphite felt with excellent conductivity can be obtained; the above-mentioned graphite felt is directly placed in a mixture of methane and hydrogen by pyrolysis to form carbon nanotubes. 1. Chemical deposition of nanofibers on graphite felt fibers, wherein the molar ratio of methane and hydrogen is 1:10, the decomposition temperature is 800°C, and the deposition time is 1h; finally graphite felt / nano short fiber functional composite electrodes can be obtained.

[0040] Such as Figure 4-Figure 5 As shown, through physical characterization, it is found that a large number of carbon nanotubes or carbon nanofibers grow on the surface of the carbon fiber of the composite electrode, the diameter of which is about 100-200...

Embodiment 3

[0042] In the present embodiment, the polyacrylonitrile-based raw felt is placed in a graphitization furnace, under N 2 Graphitization treatment is carried out in the atmosphere, wherein the treatment temperature is 2700 °C, and the treatment time is 3 hours, and graphite felt with excellent conductivity can be obtained; the above-mentioned graphite felt is directly placed in a mixture of methane and hydrogen by pyrolysis to realize carbon nanotubes. 1. Chemical deposition of nanofibers on graphite felt fibers, wherein the molar ratio of methane and hydrogen is 1:10, the decomposition temperature is 800°C, and the deposition time is 1h; finally graphite felt / nano short fiber functional composite electrodes can be obtained.

[0043] Through physical characterization, it is found that a large number of carbon nanotubes or carbon nanofibers grow on the surface of the carbon fiber of the composite electrode, the diameter of which is about 100-200nm, and its conductivity is 191.7mS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com