Method for realizing denitration in solid-gas conversion furnace and use equipment of method

A reformer and denitrification technology, which is applied to chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as increased operating costs, easy poisoning of catalysts, and performance degradation of air preheaters, and overcomes the need for large investment in catalysts and overcoming The effect of high reaction temperature and improved mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

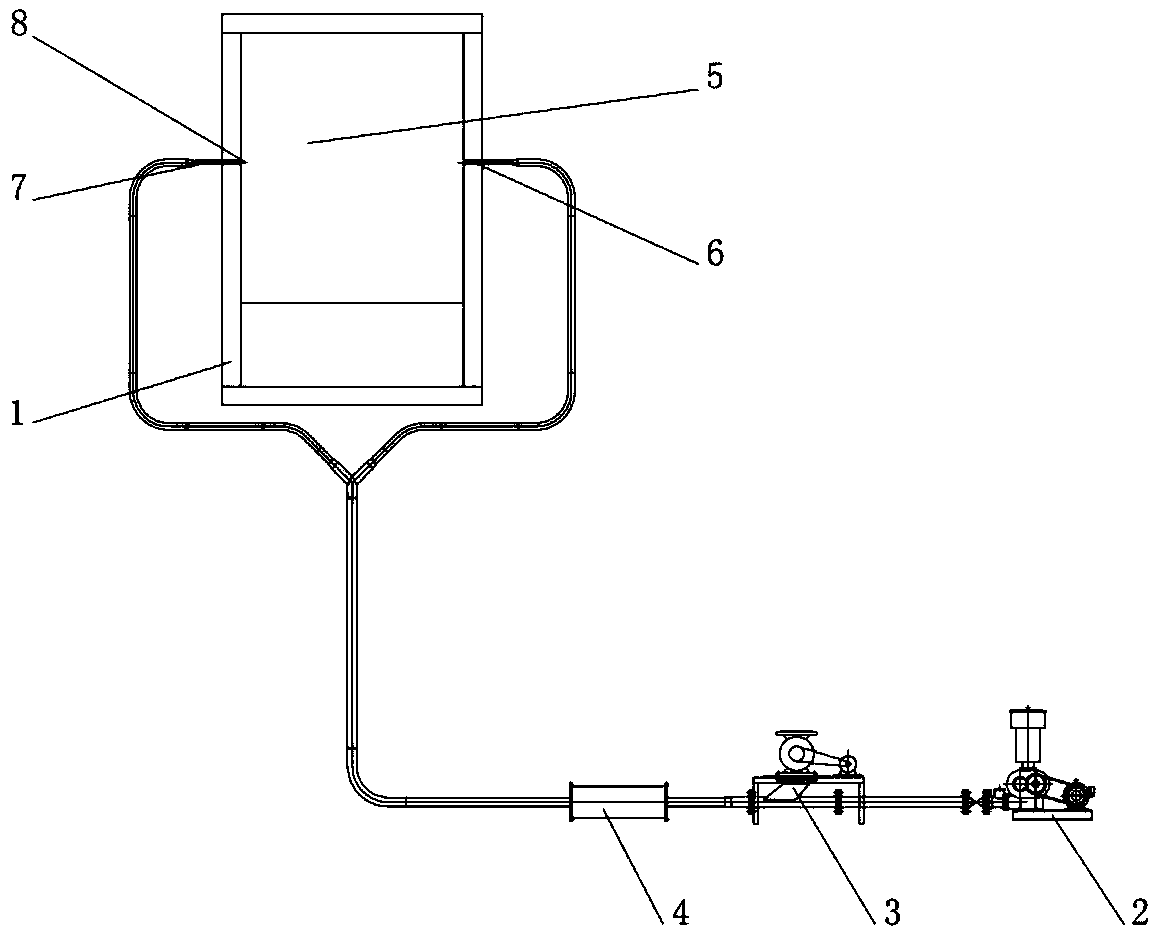

[0042] like figure 1 As shown, a method for denitrification in a solid-gas reformer provided in this embodiment includes the following steps:

[0043] Firstly, the solid denitrification substance is converted into a gaseous substance through a heating gasification system; the solid denitrification substance includes a solid substance that can be gasified by heating to a certain temperature and has a denitrification effect, and the solid denitrification substance includes urea;

[0044] Then, the gaseous denitrification substance is sprayed into the furnace denitrification zone 5 inside the boiler 1, and fully mixed and reacted with the flue gas to be treated.

[0045] In this embodiment 1, if figure 1 As shown, the solid denitrification agent urea CON2H4 is heated to 160°C-1000°C to gasify and then mainly decomposes into ammonia NH3, which is sprayed into the furnace denitrification zone 5 inside the boiler 1 to react with nitrogen oxides in the flue gas to form Nitrogen and...

Embodiment 2

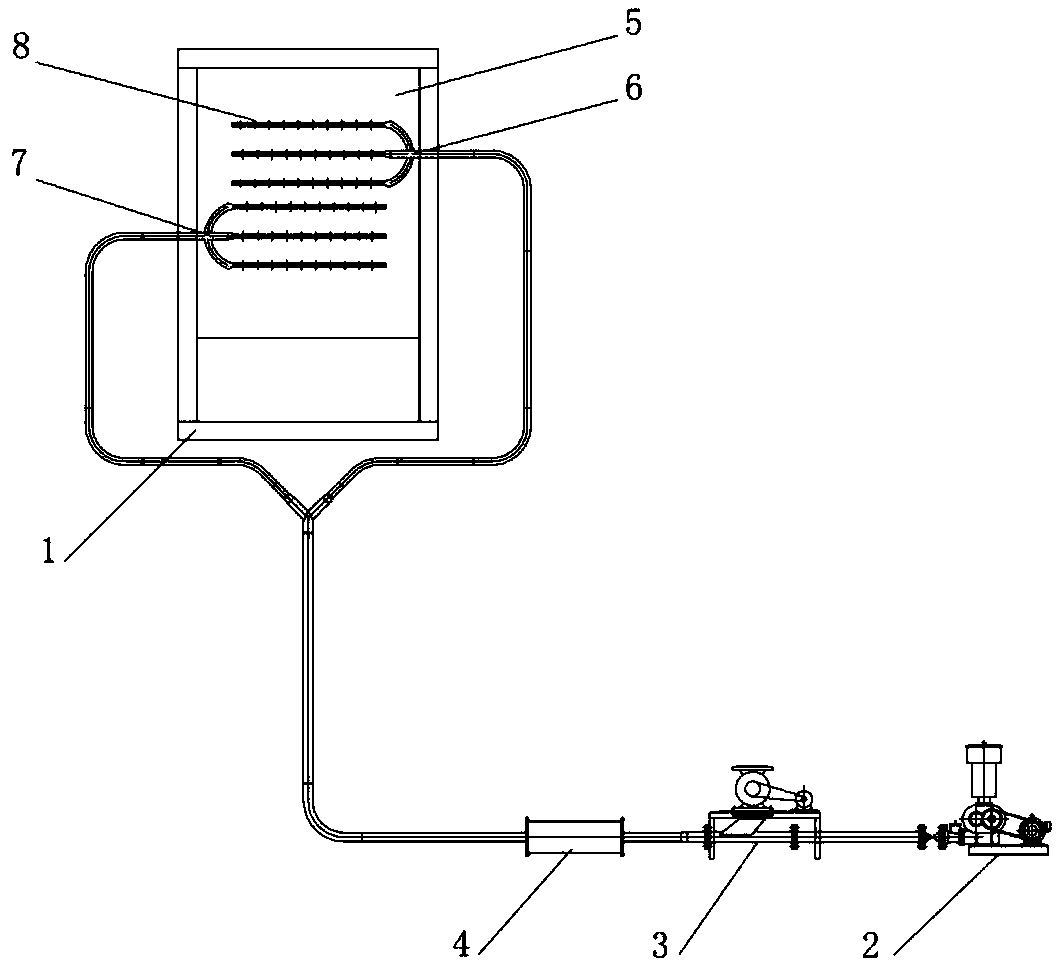

[0053] Embodiment 2: Adopt the supporting equipment of the method for denitrification in the solid-gas reformer of the present invention, such as figure 2 As shown, the combination of several spraying points 8, the first spray gun device 6, and the second spray gun device 7 presents a grid-like and or regular layer network arrangement, and the spraying points 8 are arranged horizontally in multiple rows, and the spraying points 8 rows arranged longitudinally.

Embodiment 3

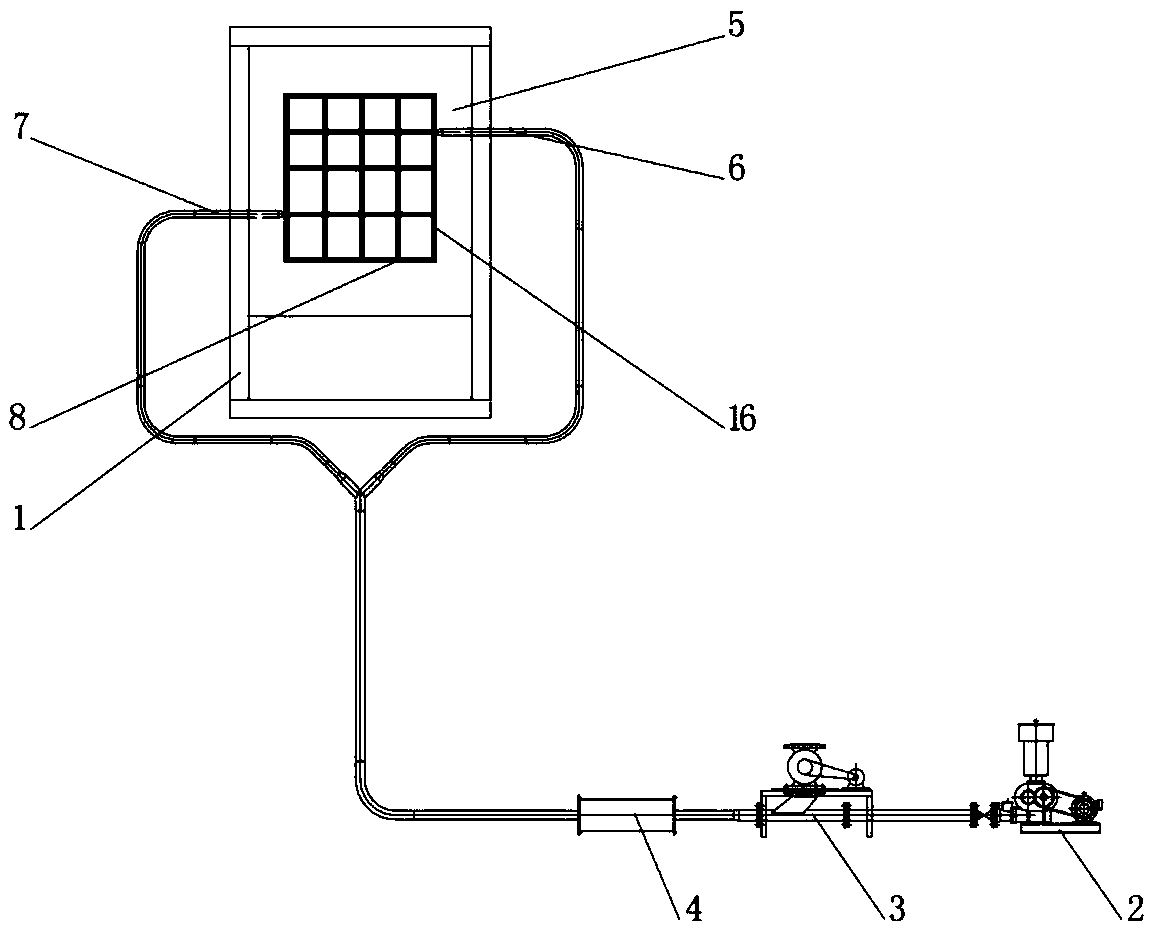

[0054] Embodiment 3: Adopt the supporting equipment of the method for denitrification in the solid-gas reformer of the present invention, such as image 3 As shown, several spraying points 8, some first spray gun devices 6, and several second spray gun devices 7 are combined into a jet net layer 16, and a plurality of jetting points 8 on the jet net layer 16 are multi-layered. regular grid arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com