Preparation method and application of zirconium-based metal-organic complex UiO-66/foam carbon composite material

A technology of organic complexes and composite materials, which is applied in the field of preparation of zirconium-based metal-organic complex UiO-66/foamed carbon composite materials, can solve the problems of reduced specific surface area of adsorbents, affecting adsorption performance, and reduced durability. Easy to separate and recover, fast mass transfer rate, avoid aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

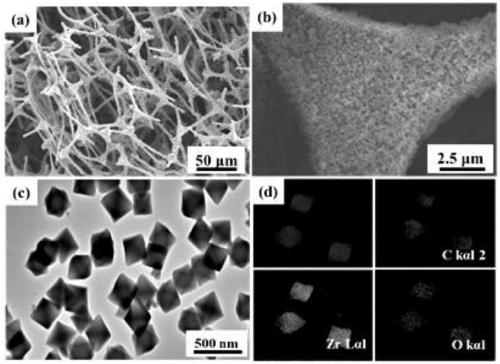

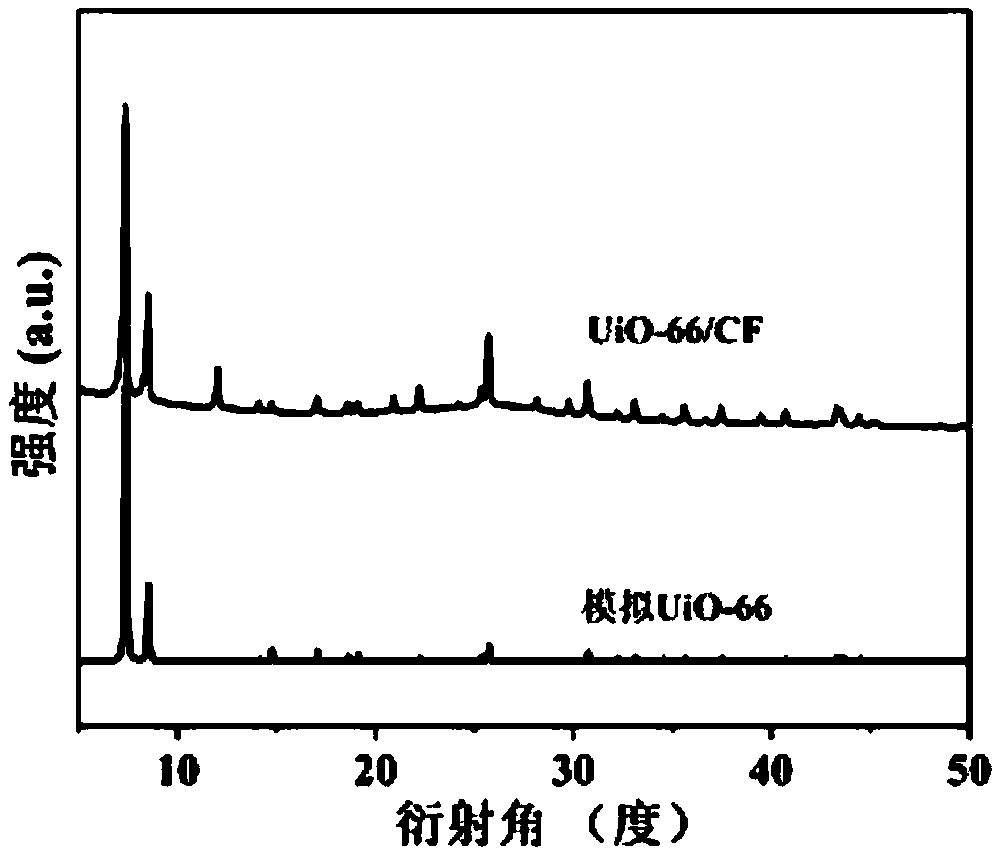

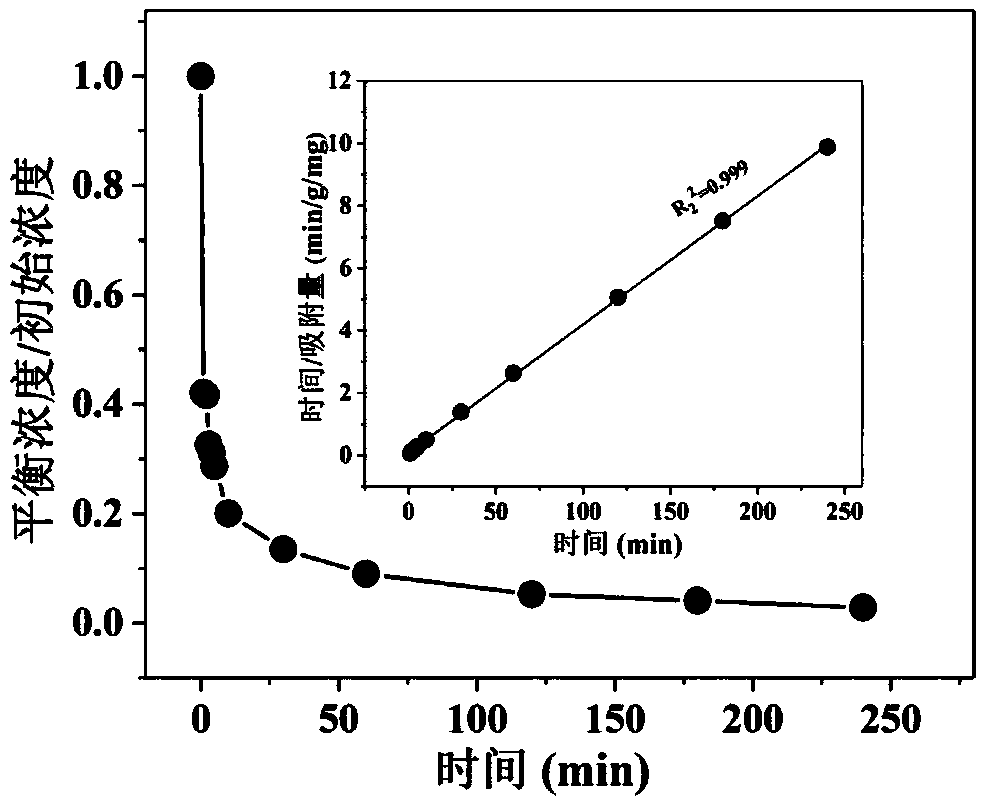

[0026] A kind of preparation method of zirconium-based metal-organic complex UiO-66 / foam carbon composite material, with ZrCl 4 As the metal source, terephthalic acid as the ligand, and adding foam carbon, adopts one-step hydrothermal synthesis, which specifically includes the following steps:

[0027] (1) Cut the melamine sponge into blocks, the size of which is 1.5cm×3cm×5cm, and put it in N 2 Calcined at 750°C for 1.5h in an atmospheric tube furnace, and acidified with 2.5mol / L nitric acid at 115°C for 1.5h to obtain foam carbon;

[0028] (2) 0.45mmol ZrCl 4 and 0.45mmol terephthalic acid were added to N,N-dimethylformamide, wherein every 1mmol of terephthalic acid used 60ml of N,N-dimethylformamide, followed by adding glacial acetic acid and stirring for 25min, wherein The molar ratio of terephthalic acid to glacial acetic acid is 1:8, and ZrCl is added to it 4 Foam carbon with 10% mass was treated with ultrasonic mixing for 25 minutes; then the mixed solution was put i...

Embodiment 2

[0030] A kind of preparation method of zirconium-based metal-organic complex UiO-66 / foam carbon composite material, with ZrCl 4 As the metal source, terephthalic acid as the ligand, and adding foam carbon, adopts one-step hydrothermal synthesis, which specifically includes the following steps:

[0031] (1) Cut the melamine sponge into blocks, the size of which is 1.5cm×3cm×5cm, and put it in N 2 Calcined at 800°C for 2h in a tubular furnace in the atmosphere, and acidified with 3.0mol / L nitric acid at 120°C for 2h to obtain foam carbon;

[0032] (2) 0.45mmol ZrCl 4 and 0.45 mmol of terephthalic acid were added to N, N-dimethylformamide, wherein 65 ml of N, N-dimethylformamide was used for every 1 mmol of terephthalic acid, followed by adding glacial acetic acid and stirring for 30 min, wherein The molar ratio of terephthalic acid to glacial acetic acid is 1:10, and ZrCl is added to it 4 Foam carbon with 10% mass was ultrasonically mixed for 30 minutes; then the mixed soluti...

Embodiment 3

[0044] A kind of preparation method of zirconium-based metal-organic complex UiO-66 / foam carbon composite material, with ZrCl 4 As the metal source, terephthalic acid as the ligand, and adding foam carbon, adopts one-step hydrothermal synthesis, which specifically includes the following steps:

[0045] (1) Cut the melamine sponge into blocks, the size of which is 1.5cm×3cm×5cm, and put it in N 2 Calcined at 850°C for 2.5h in a tubular furnace in the atmosphere, and acidified with 3.5mol / L nitric acid at 125°C for 2.5h to obtain foam carbon;

[0046] (2) 0.45mmol ZrCl 4 and 0.45 mmol of terephthalic acid were added to N, N-dimethylformamide, wherein 70 ml of N, N-dimethylformamide was used for every 1 mmol of terephthalic acid, followed by adding glacial acetic acid and stirring for 35 minutes, wherein The molar ratio of terephthalic acid to glacial acetic acid is 1:12, and ZrCl is added to it 4 Foam carbon with 10% mass was ultrasonically mixed for 35 minutes; then the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com