Enrichment device for quickly and continuously separating micro-plastics and use method thereof

A technology for separation, enrichment and microplastics, which is applied in the fields of plastic recycling, recycling technology, mechanical material recycling, etc. Micro-plastic separation and other problems, to achieve the effect of simple structure, easy to carry and move, and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Select 5 sampling points (S1, S2, S3, S4, S5) from the seabed sediments collected by an organization in the vicinity of China's coastal waters, weigh 500g of the crude product and place it on a watch plate to air-dry to remove large stones and biomass and sundries to obtain Sediment A; place Sediment A in a mortar and grind it, and use a steel sieve with a large aperture of 5-10 mm to sieve to obtain Sediment B; weigh 300 g of Sediment B in a beaker, and add Stir with 10mL of deionized water, slowly add 20mL of 30% hydrogen peroxide dropwise, and after about 3 hours of reaction, dry in an oven at 80°C and grind to obtain sediment C, which is used as a sediment sample for sieving microplastics. Preparation of flotation liquid: at room temperature, prepare saturated sodium chloride solution and alkaline rhamnolipid aqueous solution and mix them in a ratio of 8:2 as the flotation liquid for later use.

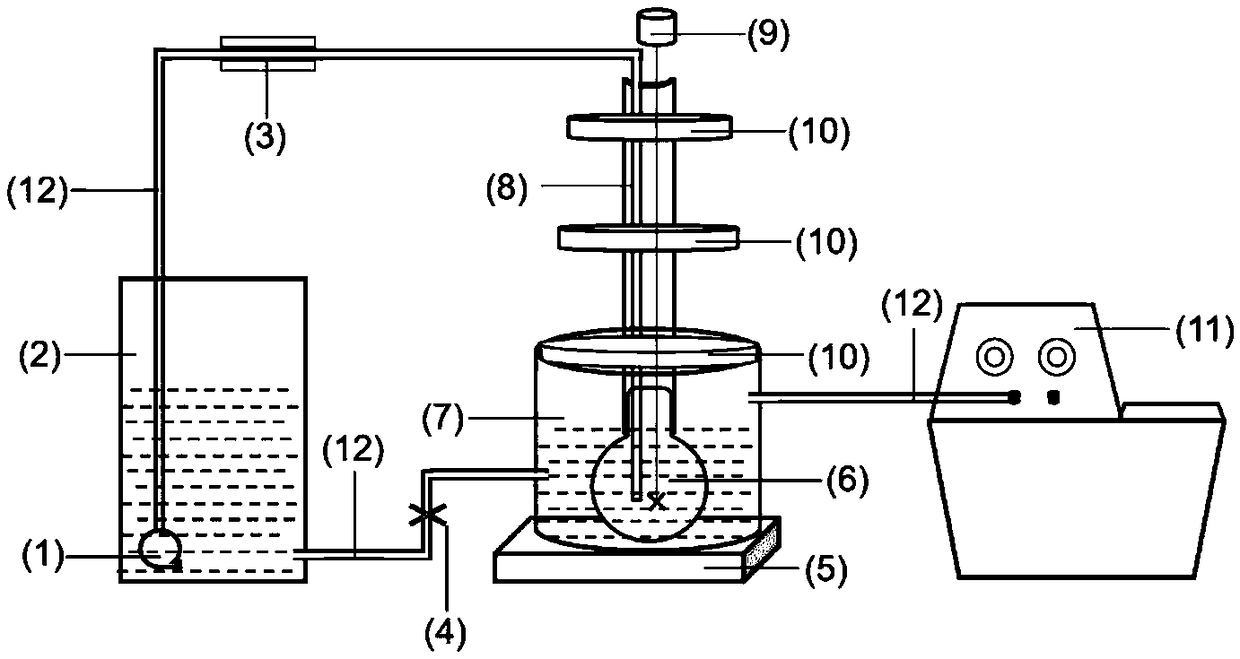

[0055] Such as figure 1 As shown, add the pre-treated sediment sample...

Embodiment 2

[0063] Weigh 2.04g of purchased linear low-density polyethylene particles (with a particle size of about 2-3mm), and count 85 particles under a stereomicroscope, add them to a 250mL beaker filled with 300g of soil, and mix them evenly as a simulated sample. Sediment samples.

[0064] Add the simulated sediment sample prepared in the sample bottle; the prepared flotation solution is saturated sodium chloride solution; the selection of the screen is the upper sieve pan (40 mesh sieve), the middle sieve pan (not put) and the lower sieve Sieve the disc (common filter paper), and dry the obtained sample in an oven at 80° C., and the other operating steps are consistent with Example 1.

[0065] A total of 2.09g of microplastic particles were obtained in the final three-layer sieving, and 85 microplastic particles were observed and counted under a stereo microscope, and the obtained plastic particles were dried and processed. The recovery rate of its samples reaches 100%, and there ...

Embodiment 3

[0067] Weigh 1.54g of purchased polypropylene plastic granules (particle size 2-3mm), put them into a pulverizer and pulverize them for 5 minutes, add all the obtained plastic pulverized granules into a 250mL beaker filled with 300g of soil, mix Uniform, as a simulated sediment sample.

[0068] Add the simulated sediment sample prepared in the sample bottle; the prepared flotation solution is a saturated sodium chloride solution; the selection of the screen is the upper sieve pan (40 mesh sieve), the middle sieve pan (100 mesh sieve) and the lower sieving disc (0.45 μm filter membrane), other operating steps are consistent with Example 1.

[0069] A total of 1.46g of microplastic particles were obtained in the final three-layer sieving, and the recovery rate of the sample reached 94.8%. Among them, the microplastic particles in the lower sieving tray contained a little sediment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com