Method for starting total biological phosphorus removal AOO process

A biological phosphorus removal, all-biological technology, applied in the field of urban sewage treatment and resource utilization, can solve the problems of difficulty in stabilization, complex process procedures, easy sludge expansion and difficulty in stabilization, etc., achieving stable operation, high startup success rate, and saving exposure. air volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

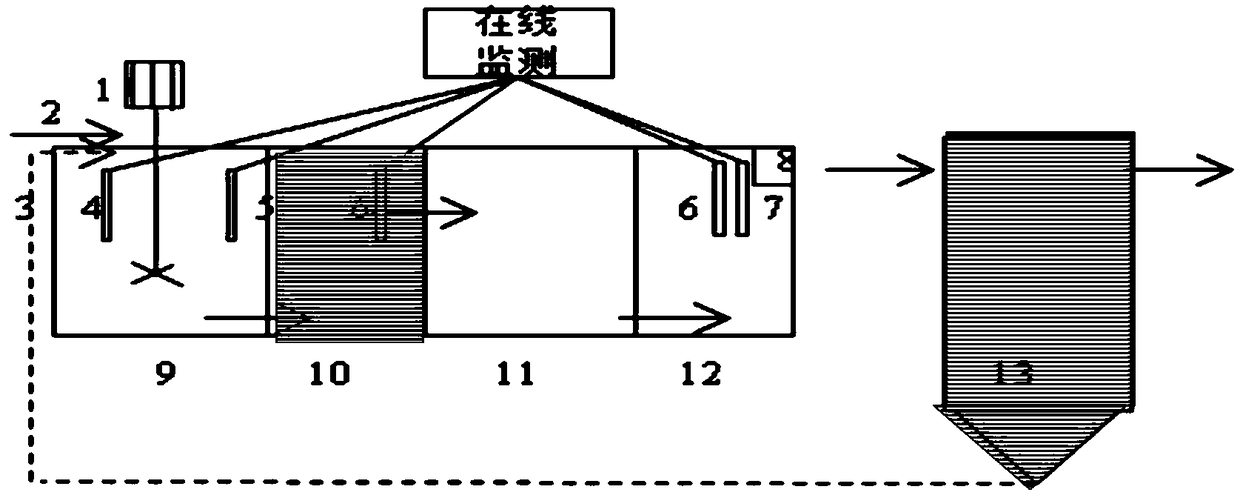

[0044] Such as figure 1 Shown: The reactor is in the form of a continuous flow baffle AO reactor, with agitator 1, water inlet 2, return pipe 3, testing equipment pH meter 4, testing equipment ORP meter 5, dissolved oxygen meter 6, testing equipment pollution Mud concentration meter 7, overflow port 8, anaerobic section 9, aerobic first section 10, aerobic middle section 11, aerobic final section 12, sedimentation tank 13; Microporous aeration heads are installed at the bottom of the middle section of the aerobic section, the middle section of the aerobic section, and the aeration volume is controlled by a gas flow meter.

[0045] The volume of the anaerobic section: the total volume of the reactor is 1:3.3; the volume of the first aerobic section: the total volume ratio of the aerobic section is 1:3.3.

[0046] The reaction temperature is low (14-18°C). First, the activated sludge retrieved from the sewage plant is inoculated in the continuous flow baffle AO reactor. The ini...

Embodiment 2

[0059] Influent water quality and reactor form are the same as above.

[0060] The reaction temperature is normal temperature (20-25° C.). Firstly, inoculate the inoculation sludge phosphorus removal activity of 40%-75% in the continuous flow baffle AO reactor, the inoculation volume is 60L, and the sludge concentration is 1500mg / L.

[0061] A kind of start-up method of whole biological phosphorus removal AOO process, comprises the following steps:

[0062] The first step: the domestication and enrichment stage before start-up, including:

[0063] (1) Sludge volume amplification and optimal aeration volume search stage: Fill the reactor containing domesticated sludge with actual domestic sewage, adopt anaerobic and aerobic internal reflux cycle, control volume load 2g / L, total The aeration rate is 30ml / min, and the dissolved oxygen concentration in each section is controlled at 2mg / L~4mg / L. After the sludge concentration in the reactor increases to 2000mg / L, the continuous wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com