Sludge dehydrating agent as well as preparation method and application thereof

A technology of sludge dehydrating agent and water supply sludge, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high cost of water supply sludge and unfavorable industrial production, and achieve a wide range The effect of developing space and application value, improving resource utilization, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

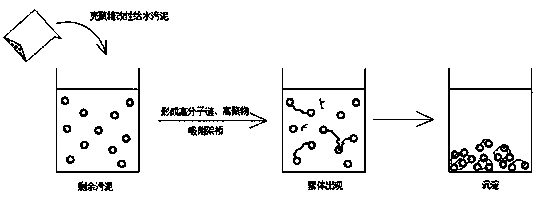

Method used

Image

Examples

Embodiment 1

[0032] 1) The water supply sludge taken from the water supply plant is washed with clean water for 3 times, and filtered to obtain a water supply sludge slurry with a water content of 90%;

[0033] 2) Weigh a certain amount of chitosan and dissolve it with 1% acetic acid solution to obtain a chitosan solution with a concentration of 2%;

[0034] 3) Take the feedwater sludge slurry prepared in step 1) and the chitosan solution prepared in step 2), and mix them at a volume ratio of 1:2 to obtain a mixed solution, and then add epichlorohydrin (ECH) at a concentration of 1 g / L NaOH solution to obtain a solidified cross-linking solution with a volume fraction of 3%, and then add the mixed solution dropwise to the solidified cross-linked solution, and obtain a particle size of 0.4-0.6 cm after curing and cross-linking at 40°C for 8 hours. solid pellets;

[0035] 4) Filter out the solid pellets obtained in step 3), wash them with deionized water, and dry them in a drying oven at 60...

Embodiment 2

[0037] 1) The water supply sludge taken from the water supply plant is washed with clean water for 3 times, and filtered to obtain a water supply sludge slurry with a water content of 90%;

[0038] 2) Weigh a certain amount of chitosan and dissolve it with 1% acetic acid solution to obtain a chitosan solution with a concentration of 3%;

[0039] 3) Take the feedwater sludge slurry prepared in step 1) and the chitosan solution prepared in step 2), and mix them at a volume ratio of 1:2 to obtain a mixed solution, and then add epichlorohydrin (ECH) at a concentration of 1 g / L NaOH solution to obtain a solidified cross-linking liquid with a volume fraction of 2%, and then add the mixed solution dropwise to the solidified cross-linked liquid, and obtain a particle size of 0.4-0.6 cm after curing and cross-linking at 50°C for 12 hours. solid pellets;

[0040] 4) Filter out the solid pellets obtained in step 3), wash them with deionized water, and dry them in a drying oven at 60°C ...

Embodiment 3

[0042] 1) The water supply sludge from the water supply plant is washed with clean water for 3 times, and filtered to obtain the water supply sludge slurry with a water content of 80%;

[0043] 2) Weigh a certain amount of chitosan and dissolve it with 1% acetic acid solution to obtain a chitosan solution with a concentration of 1%;

[0044] 3) Take the water supply sludge slurry prepared in step 1) and the chitosan solution prepared in step 2), and mix them at a volume ratio of 1:2 to obtain a mixed solution, and then add epichlorohydrin (ECH) at a concentration of 3g / A volume fraction of 4% of the solidified cross-linking solution was obtained in a NaOH solution of 1 L, and then the mixed solution was added dropwise to the solidified cross-linked liquid, and solid particles with a particle size of 0.5 cm were obtained after curing and cross-linking at 60°C for 6 hours. ball;

[0045] 4) Filter out the solid pellets obtained in step 3), wash them with deionized water, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com