Polystyrene-graphene oxide composite bulk material, graphene-based porous bulk material and preparation methods of polystyrene-graphene oxide composite bulk material and graphene-based porous bulk material

A graphene composite and polystyrene technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problem of unsatisfactory material densification and mechanical properties, uneven dispersion of graphene and its derivatives, complex reactions Conditions and other issues, to achieve the effect of low reaction conditions and equipment requirements, hard texture and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

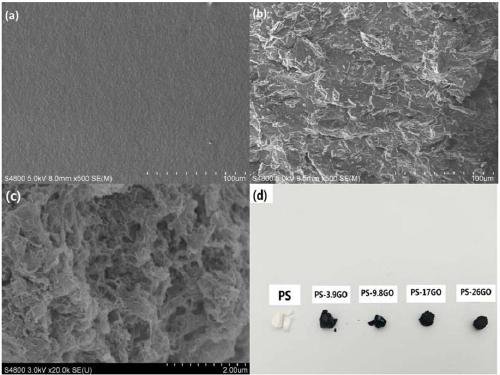

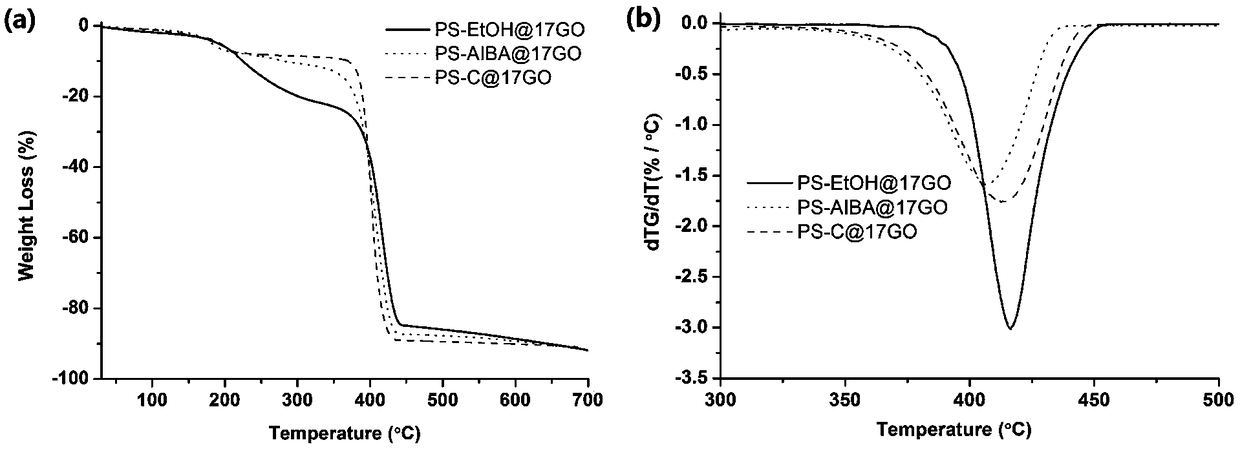

Embodiment 1

[0041] (1) Add 100mL deionized water, 5.5mL styrene, and 1.3g sodium lauryl sulfate into a four-necked flask, fix it in a water bath with an iron stand, and connect the four-necked flasks to N 2 Air inlet, thermometer, condenser tube and rubber stopper, stirring speed is 400r / min. Then pass into N 2 , use a flowmeter to control the flow rate of about 40mL / min, open the cooling water into the condenser, inject 6.8mL potassium persulfate (0.01g / mL) into the flask through the rubber stopper with a syringe, set the heating temperature of the water bath to 70°C, and keep 6h, the PS microsphere emulsion was obtained, and the particle size distribution of the obtained PS microsphere emulsion was observed by a transmission electron microscope (TEM), and the particle size was about 25nm;

[0042] (2) Mix 4g of graphite powder, 2g of sodium nitrate and 100mL of concentrated sulfuric acid (98%), stir in an ice bath, and slowly add 8g of KMnO 4 , continue stirring for 1h. After that, t...

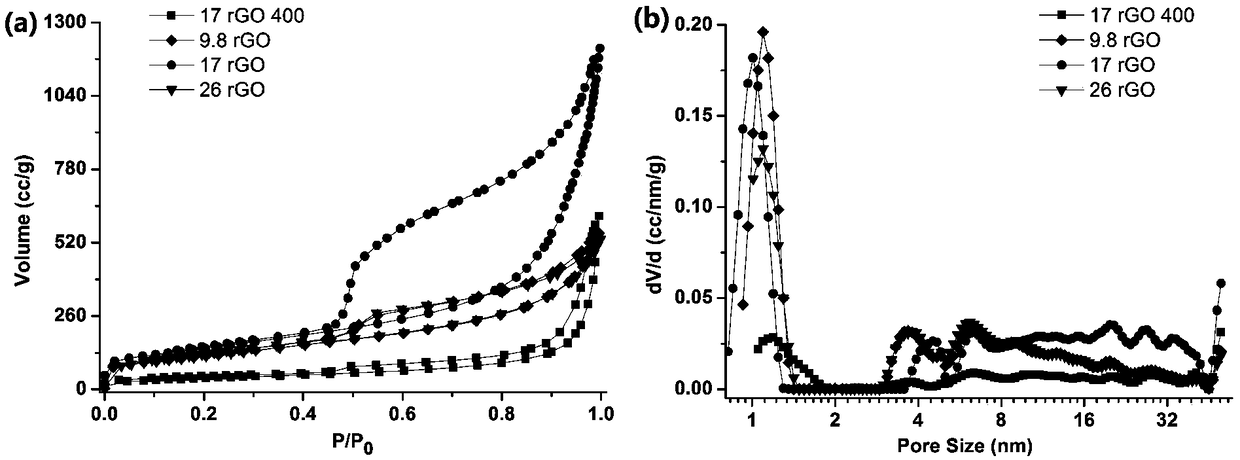

Embodiment 2

[0046] The difference between this embodiment and Example 1 is: 78mg GO powder is added in step (3), that is, the added GO is 26wt% of the total mass of the polystyrene-graphene oxide mixed emulsion, and other parameters are the same as in Example 1 Similarly, the obtained polystyrene-graphene oxide composite bulk material is marked as PS-26GO, and the obtained graphene-based porous bulk material is marked as 26rGO-800.

Embodiment 3

[0048] The difference between this embodiment and Example 1 is that 24mg GO powder is added in step (3), that is, the added GO is 9.8wt% of the polystyrene-graphene oxide mixed emulsion, and other parameters are the same as in Example 1 . The obtained polystyrene-graphene oxide shaped bulk material is marked as PS-9.8GO, and the obtained graphene-based porous bulk material is marked as 9.8rGO-800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com