Yellow long-afterglow luminescent material as well as preparation method and application thereof

A technology of long afterglow luminescence and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of easy deliquescence and insufficient chemical stability, and achieve long afterglow duration, high stability and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

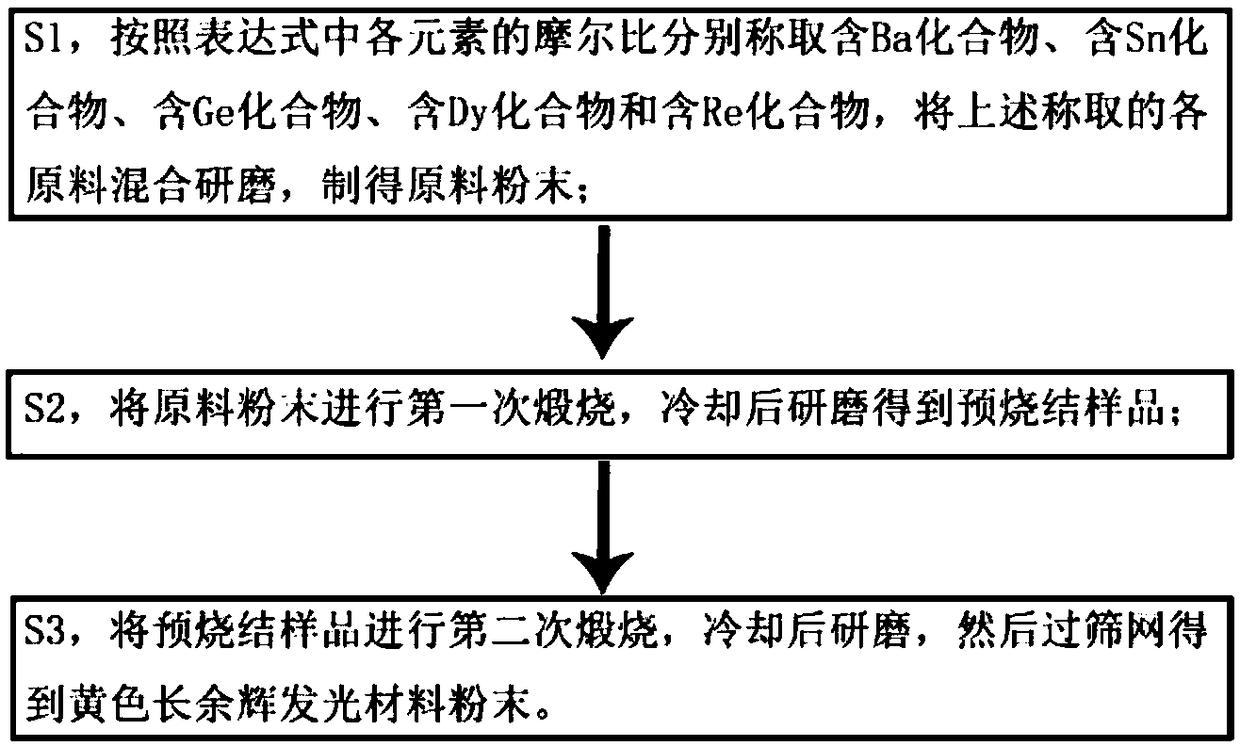

[0026] The preparation method of the above-mentioned yellow long-lasting luminescent material also provided by the embodiment of the present invention includes the following steps:

[0027] S1. Weigh the Ba-containing compound, Sn-containing compound, Ge-containing compound, Dy-containing compound and Re-containing compound according to the molar ratio of each element in the expression, mix and grind the above-mentioned raw materials to obtain raw material powder .

[0028] Further, in step S1, each of the above raw materials is selected from oxides containing corresponding elements, salts or a mixture of the two; wherein the salts are selected from nitrates and / or carbonates. In a preferred embodiment of the present invention, the Ba-containing compound can be selected from its oxide, nitrate or carbonate, the Sn-containing and Ge-containing compound can be selected from its oxide, and the Dy-containing and Re-containing compound can be selected from its oxide or nitric acid....

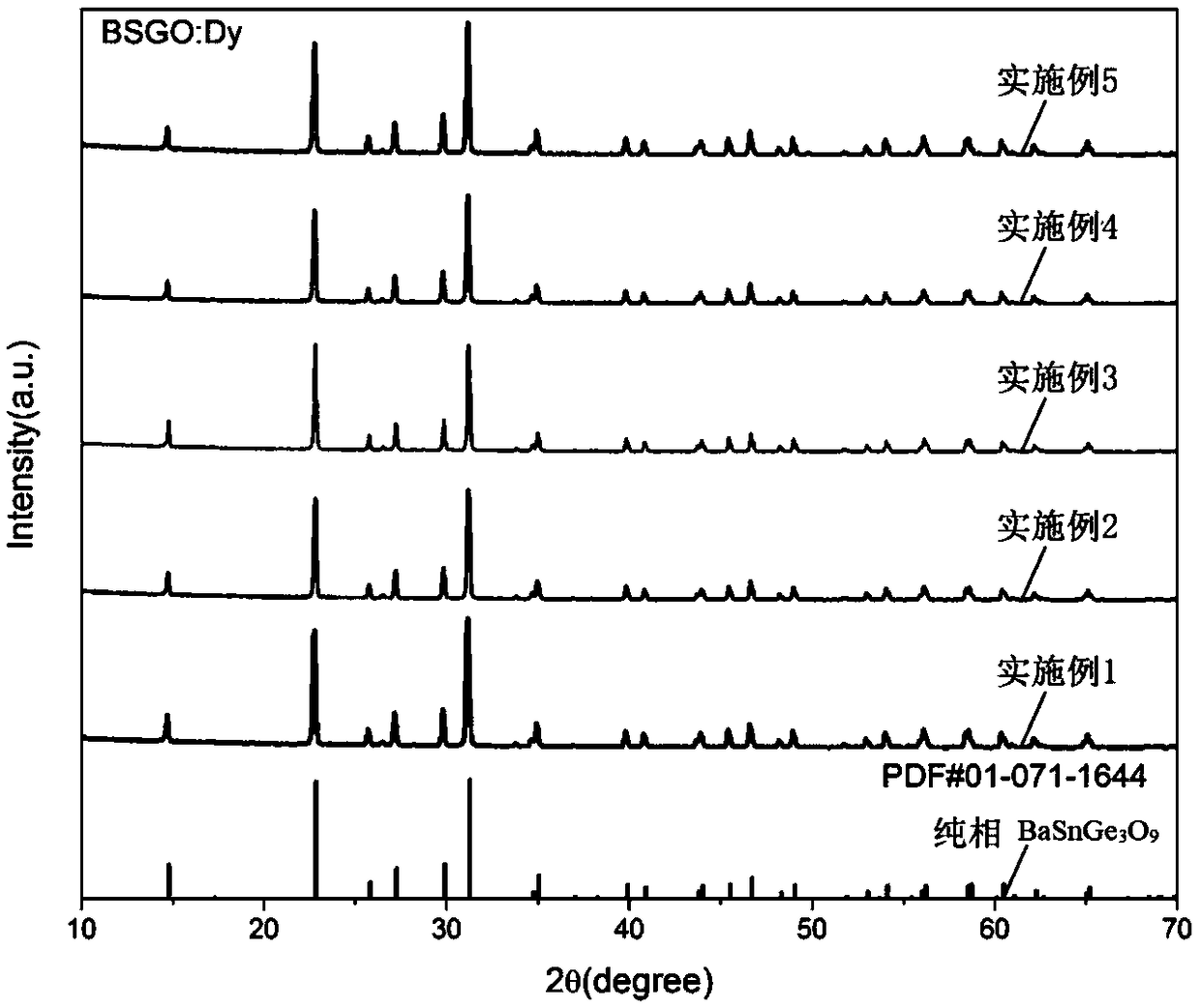

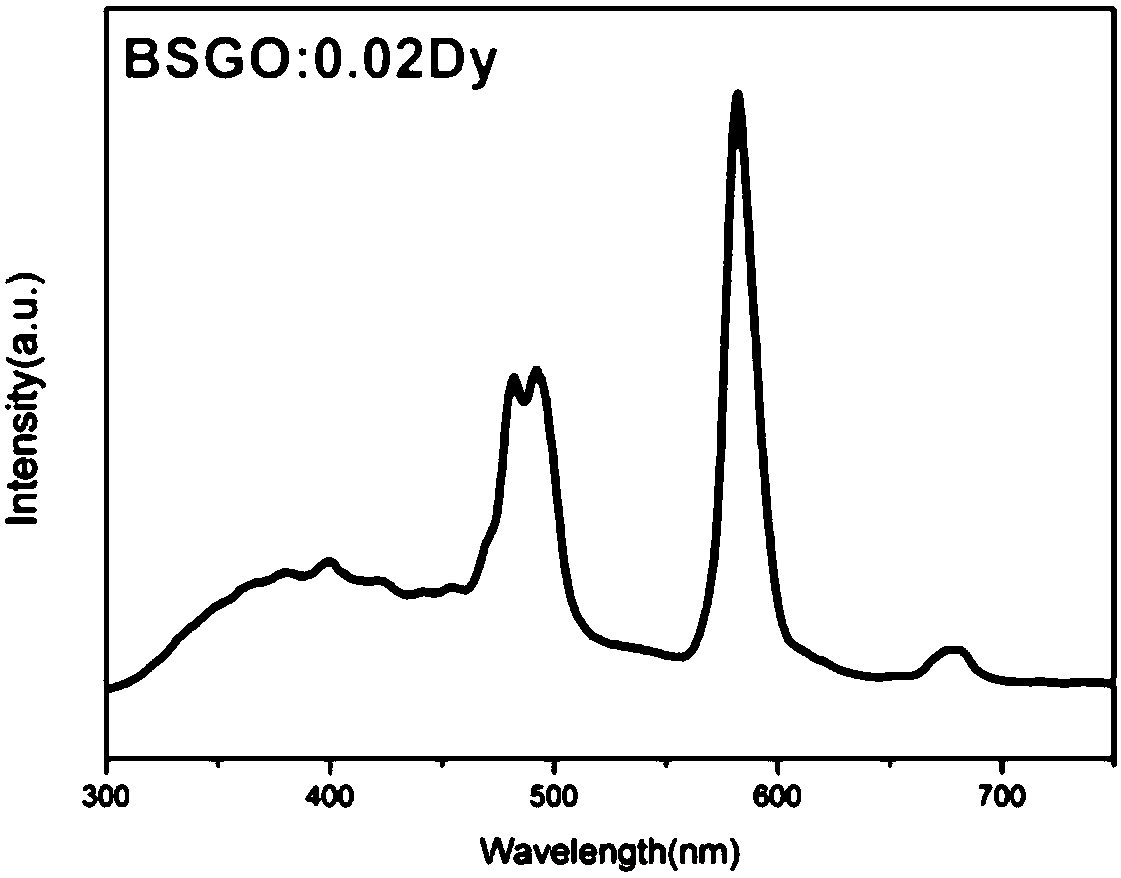

Embodiment 1~6

[0045] Embodiments 1-6 respectively provide a yellow long-lasting luminescent material, and its preparation steps are as follows:

[0046] (1) Weigh and mix the raw materials of each element according to the table below, and add absolute ethanol to grind thoroughly for 3 hours to obtain the raw material powder.

[0047]

[0048]

[0049] (2) Put the raw material powder into a high-temperature tube furnace, raise the temperature to 800°C at a rate of 5°C / min in an air atmosphere, and then lower it to 200°C at a rate of 10°C / min after burning for 2 hours, then cool naturally with the furnace to room temperature to obtain a pre-sintered sample.

[0050] (3) After the pre-sintered sample is cooled to room temperature, take it out and grind it fully, put it into the high-temperature tube furnace again, and raise the temperature to 1300°C at a rate of 7°C / min in the air atmosphere, burn it for 4 hours and then leave it in the furnace. Cool naturally to room temperature.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com