A kind of preparation method of negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult large-scale industrialization, harsh preparation conditions, and low efficiency, and achieve volume change, easy porous structure, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

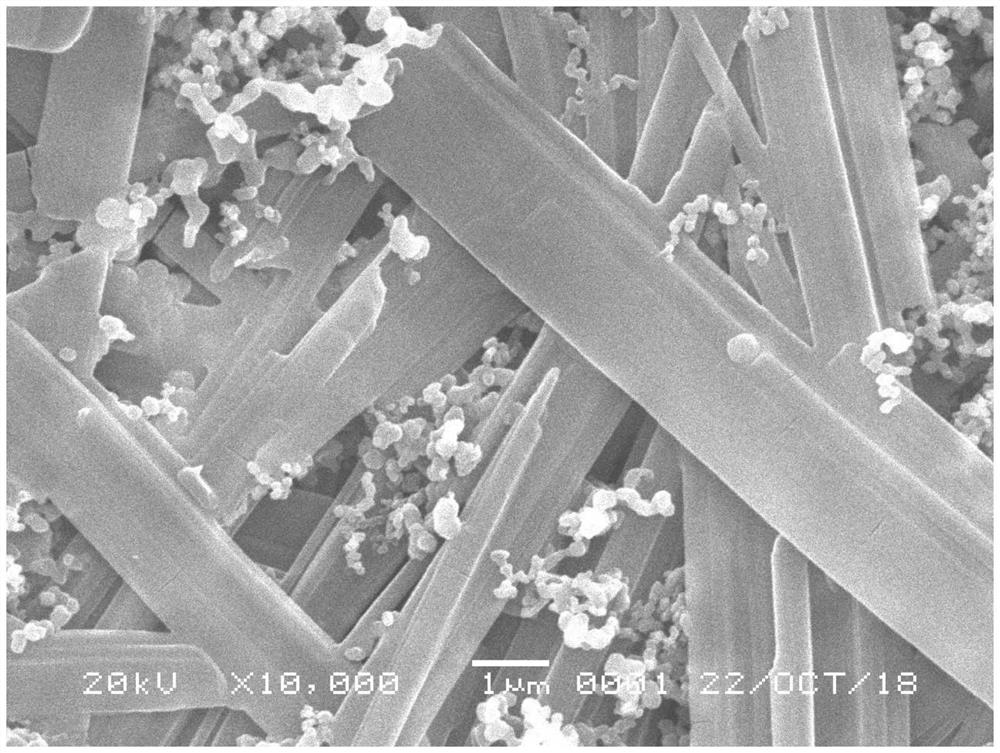

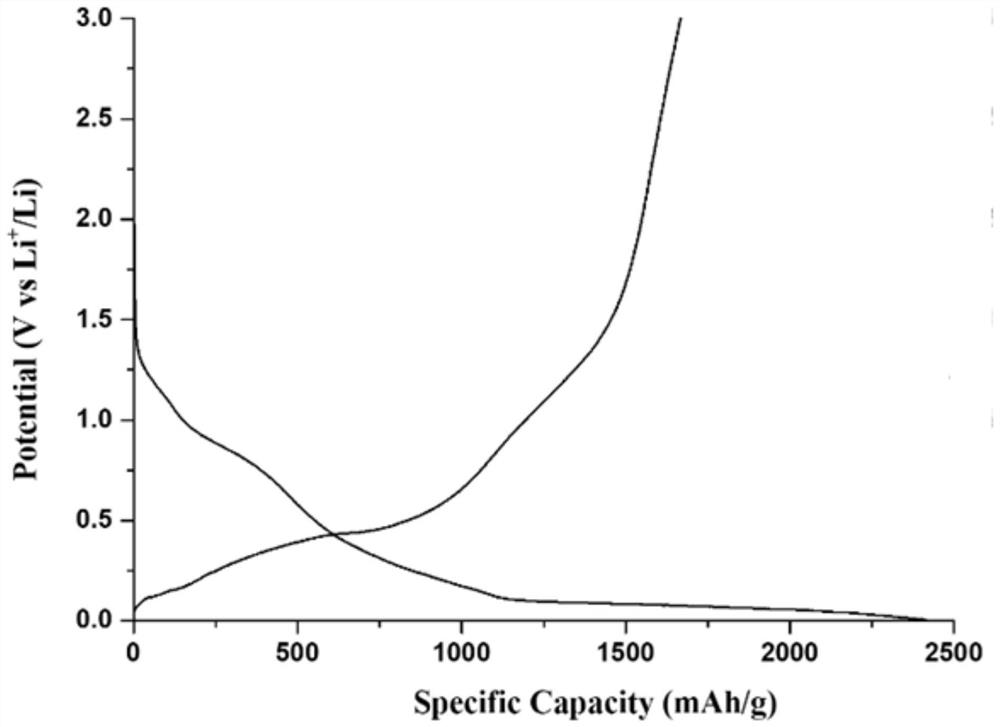

[0035] Measure 20ml of distilled water, add 630mg of trimesic acid into it, keep stirring, and add dropwise 10ml of 1mol / L KOH solution to dissolve the trimesic acid to form solution A. Weigh 100 mg of silicon powder with a particle size of 20 nm, add it into a beaker filled with 15 ml of distilled water and 2 ml of ethanol, and ultrasonically disperse for 1 hour to obtain dispersion B. Dispersion B was mixed with solution A to form mixed dispersion C. Then, under the condition of constant stirring, 2 ml of acetic acid was added dropwise to the dispersion C, and the stirring was continued for 30 min. Then it was filtered with suction to obtain a solid mixture.

[0036] The solid mixture was placed in a tube furnace, heated to 700°C for 5 hours at a rate of 2°C / min under a nitrogen atmosphere, and then cooled to room temperature to obtain a black solid substance, which was washed with distilled water to remove potassium from the material. Then, vacuum drying was performed at ...

Embodiment 2

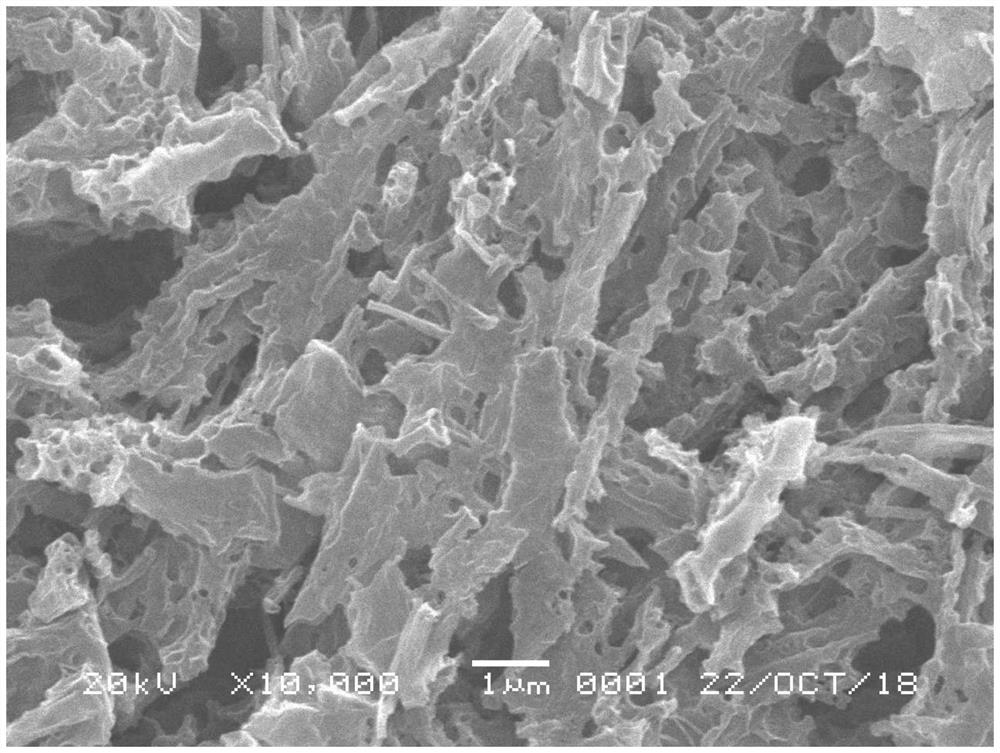

[0039] Measure 20ml of distilled water, add 630mg of trimesic acid into it, keep stirring, and add dropwise 10ml of 1mol / L NaOH solution to dissolve the trimesic acid to form solution A. Weigh 150 mg of silicon powder with a particle size of 50 nm, add it into a beaker filled with 15 ml of distilled water and 2 ml of ethanol, and ultrasonically disperse for 1 hour to obtain dispersion B. Dispersion B was mixed with solution A to form mixed dispersion C. Then, under the condition of constant stirring, 2 ml of propionic acid was added dropwise to the dispersion C, and the stirring was continued for 30 min. Then it was filtered with suction to obtain a solid mixture.

[0040] The solid mixture was placed in a tube furnace, heated at a rate of 2°C / min to 750°C for 3 hours under a nitrogen atmosphere, and then cooled to room temperature to obtain a black solid substance, which was washed with distilled water to remove potassium from the material. Then, vacuum drying was performed...

Embodiment 3

[0042] Measure 20ml of distilled water, add 630mg of trimesic acid into it, keep stirring, and dropwise add 10ml of 1mol / L ammonia water to dissolve the trimesic acid to form solution A. Weigh 150 mg of silicon powder with a particle size of 20 nm, add it into a beaker filled with 15 ml of distilled water and 2 ml of ethanol, and ultrasonically disperse for 1 hour to obtain dispersion B. Dispersion B was mixed with solution A to form mixed dispersion C. Then, under the condition of constant stirring, 2ml of formic acid was added dropwise to the dispersion C, and the stirring was continued for 30min. Then it was filtered with suction to obtain a solid mixture.

[0043] The solid mixture was placed in a tube furnace, heated at a rate of 5°C / min to 650°C for 5 hours under an argon atmosphere, and then cooled to room temperature to obtain a black solid substance, which was washed with distilled water to remove potassium from the material. Then, vacuum drying was performed at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com