An electrolyte containing a cathode protector and a lithium sulfur battery containing the electrolyte

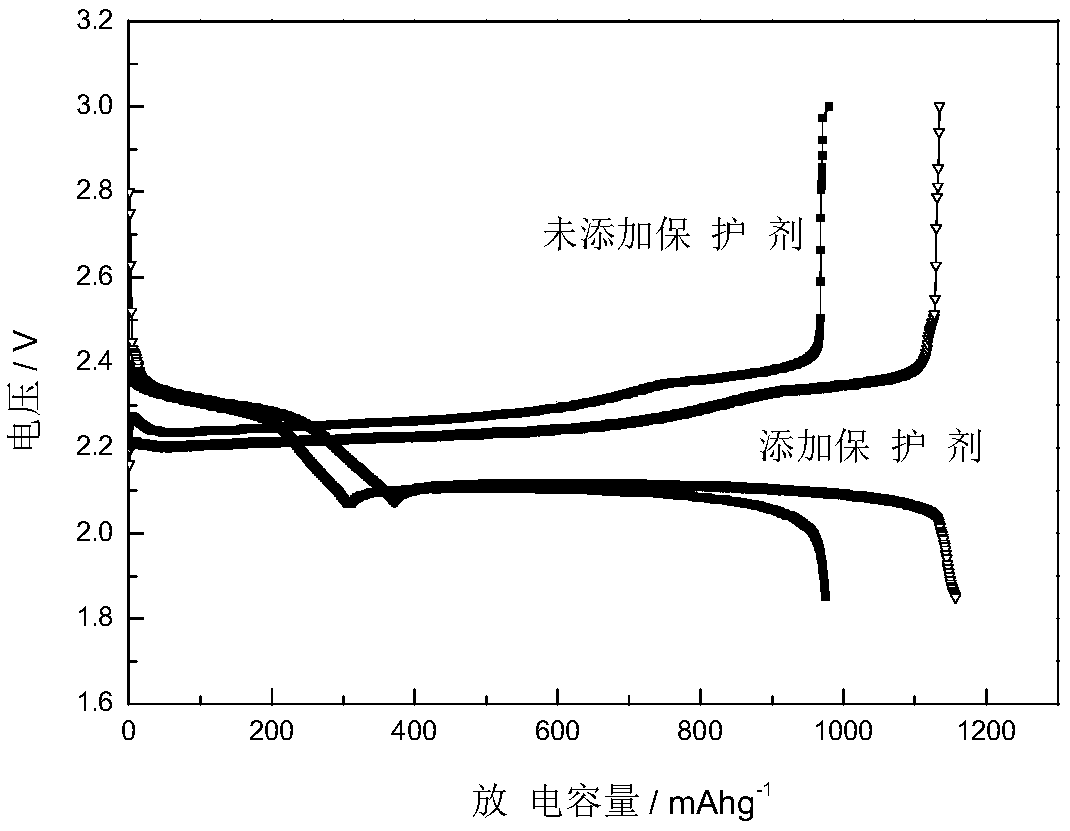

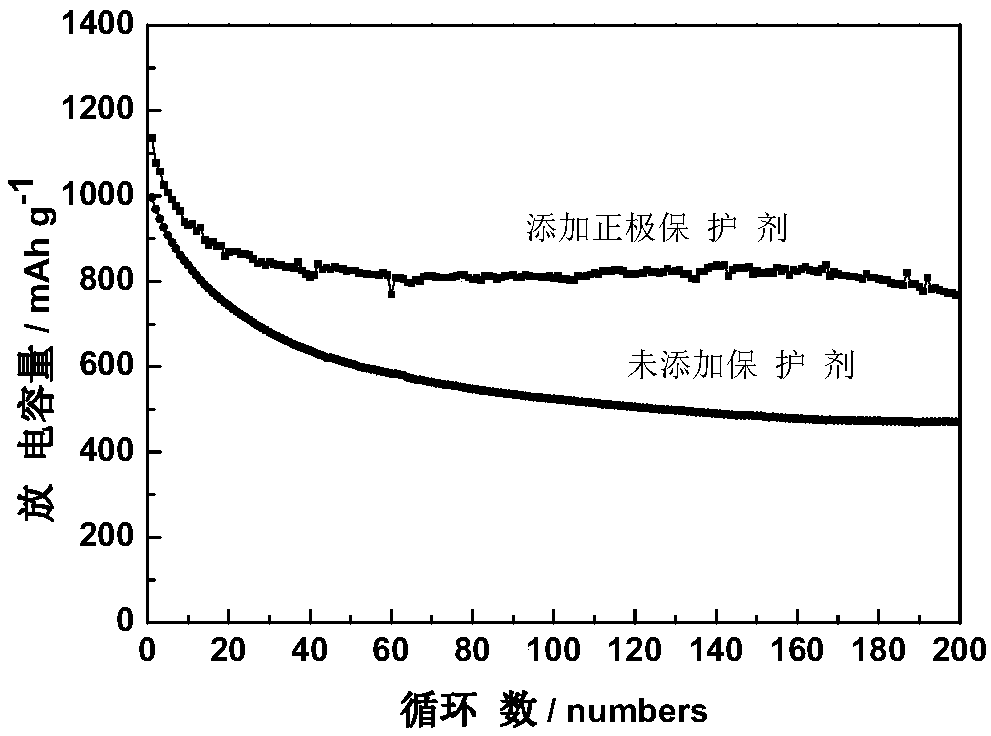

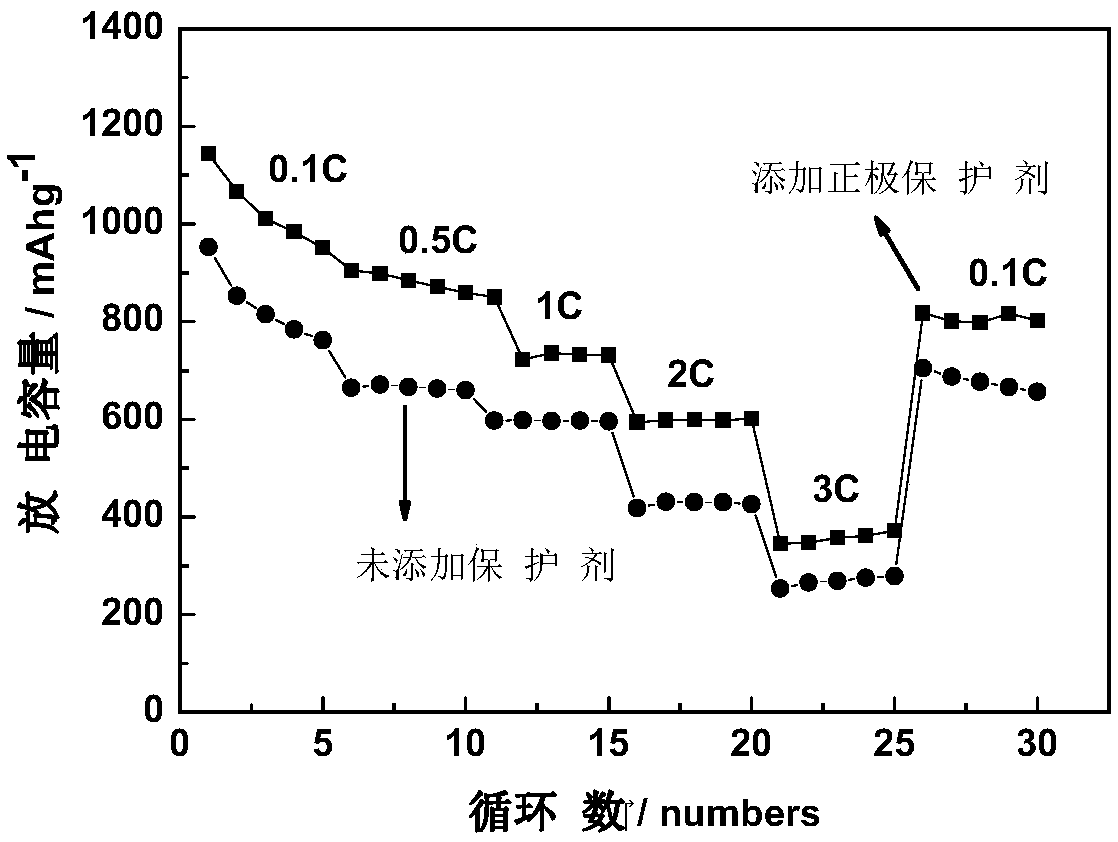

A lithium-sulfur battery and protective agent technology, applied in non-aqueous electrolyte batteries, lithium batteries, battery electrodes, etc., to achieve the effects of easy large-scale amplification, low cost, improved reversibility and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 99.5% pure (water content is 20ppm) is dissolved in the diethylene glycol dimethyl ether and makes the solution that concentration is 10%, then presses the addition amount of 0.5% The solution is injected into the standard electrolyte of the lithium-sulfur battery to prepare the electrolyte A for protection of the present invention.

[0046] The benchmark electrolyte for lithium-sulfur batteries is: 1M lithium bis(trifluoromethylsulfonyl)imide solution (LiTFSI) as the electrolyte solution, and the solvents are 1,3-dioxolane (DOL) and diethylene glycol dimethyl ether (DME) mixture (volume ratio v / v=1:1).

[0047] After uniformly mixing 20mg of commercialized Super P and 80mg of S, disperse in 1.3g of N-methylpyrrolidone (NMP), after uniform dispersion, add 24.7mg of commercialized KB carbon powder, after ultrasonication for 20min, stir for 1h, add 0.132g10wt .% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, stir for 5h, adjust the scraper to 200μm, scrape...

Embodiment 2

[0058] The purity of 99.8% (water content is 200ppm) is dissolved in dimethyl sulfoxide to make a solution with a concentration of 5%, and then its solution is injected into the lithium-sulfur battery reference electrolyte in an amount of 3% to prepare the protection of the present invention. Electrolyte A.

[0059] The standard electrolyte for lithium-sulfur batteries is: 1M lithium bis(trifluoromethylsulfonyl)imide solution (LiTFSI) is the electrolyte solution, and the solvent is dimethyl sulfoxide.

[0060] After uniformly mixing 20mg of commercial Super P and 80mg of S, disperse in 1.3g of N-methylpyrrolidone (NMP). 10wt.% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, stir for 5 hours, adjust the scraper to 200 μm, scrape and coat on the aluminum film to form a film, dry it overnight at 70 ° C, and cut it into small discs with a diameter of 14 mm. After weighing, after vacuum drying at 60°C for 24 hours, the small disc was used as the positive electrode (...

Embodiment 3

[0066] 99% pure (water content is 50ppm) is dissolved in the tetraglyme, makes the solution that concentration is 5%, then adds this solution by 0.1% addition amount in the standard electrolyte of lithium-sulfur battery, prepares the application of the present invention Protected electrolyte A.

[0067] The reference electrolyte for lithium-sulfur batteries is: 1M lithium hexafluorophosphate solution (LiPF 6 ) is an electrolyte solution, and the solvent is a mixture of dimethyl carbonate and ethylene glycol dimethyl ether (DME) (volume ratio v / v=1:1).

[0068] After uniformly mixing 20mg of commercial Super P and 80mg of S, disperse in 1.3g of N-methylpyrrolidone (NMP). 10wt.% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, stir for 5 hours, adjust the scraper to 200 μm, scrape and coat on the aluminum film to form a film, dry it overnight at 70 ° C, and cut it into small discs with a diameter of 14 mm. After weighing, after vacuum drying at 60°C for 24 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com