A low-energy chemical field-driven organic pollutant degradation catalyst and its application

A technology of organic pollutants and low energy consumption, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the target treatment pollution It has the advantages of single chemical selectivity, harsh environment, high cost and other problems, and achieves good catalytic effect, good stability and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation method of A component comprises the steps:

[0089] 1) Preparation of transition noble metal-based nanoparticles by deposition-precipitation, photoreduction or chemical synthesis;

[0090] 2) Preparation of carrier oxides;

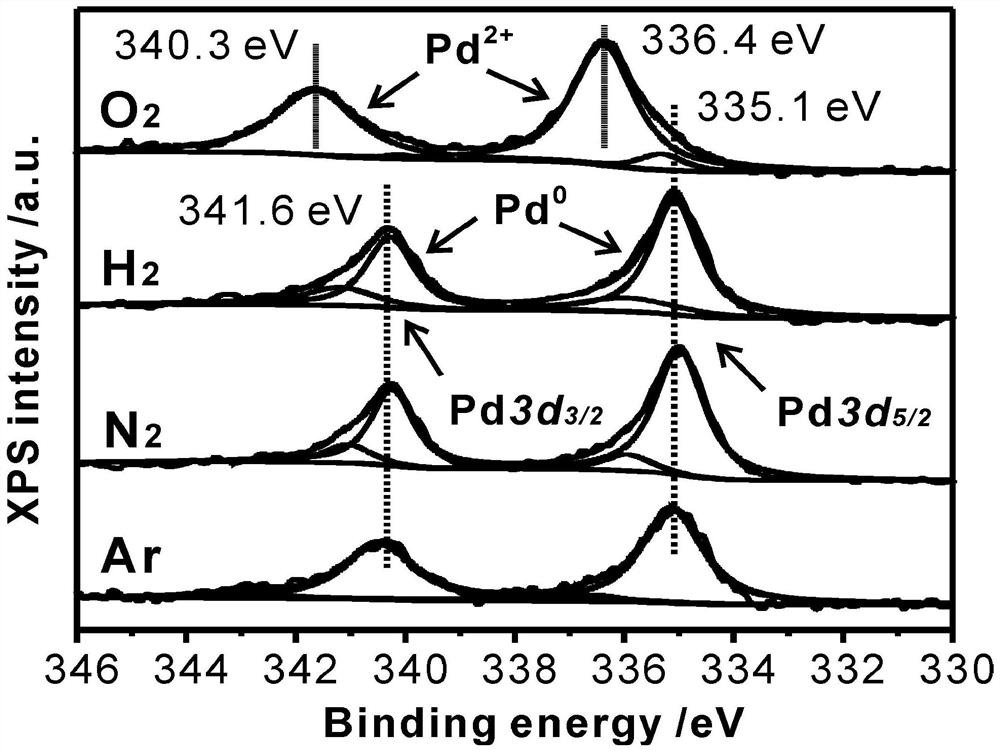

[0091] 3) The transition noble metal-based nanoparticles and the carrier oxide were prepared as a solution, and ultrasonically dispersed; the solution of the transition noble metal-based nanoparticles was added to the solution of the carrier oxide under stirring conditions, centrifuged and vacuum-dried, and the resulting solid powder In oxygen, air, nitrogen or H at a volume ratio of 5:95 2 / Ar atmosphere calcined (100-600 ℃), that is A component.

[0092] The application of the above catalysts in the degradation of organic pollutants: the organic pollutants and B component are prepared as a mixed solution; the concentration of organic pollutants is 1*10-5-0.1 mol / L; the concentration of B component is 0.1-1mol / L; then add compon...

Embodiment 1

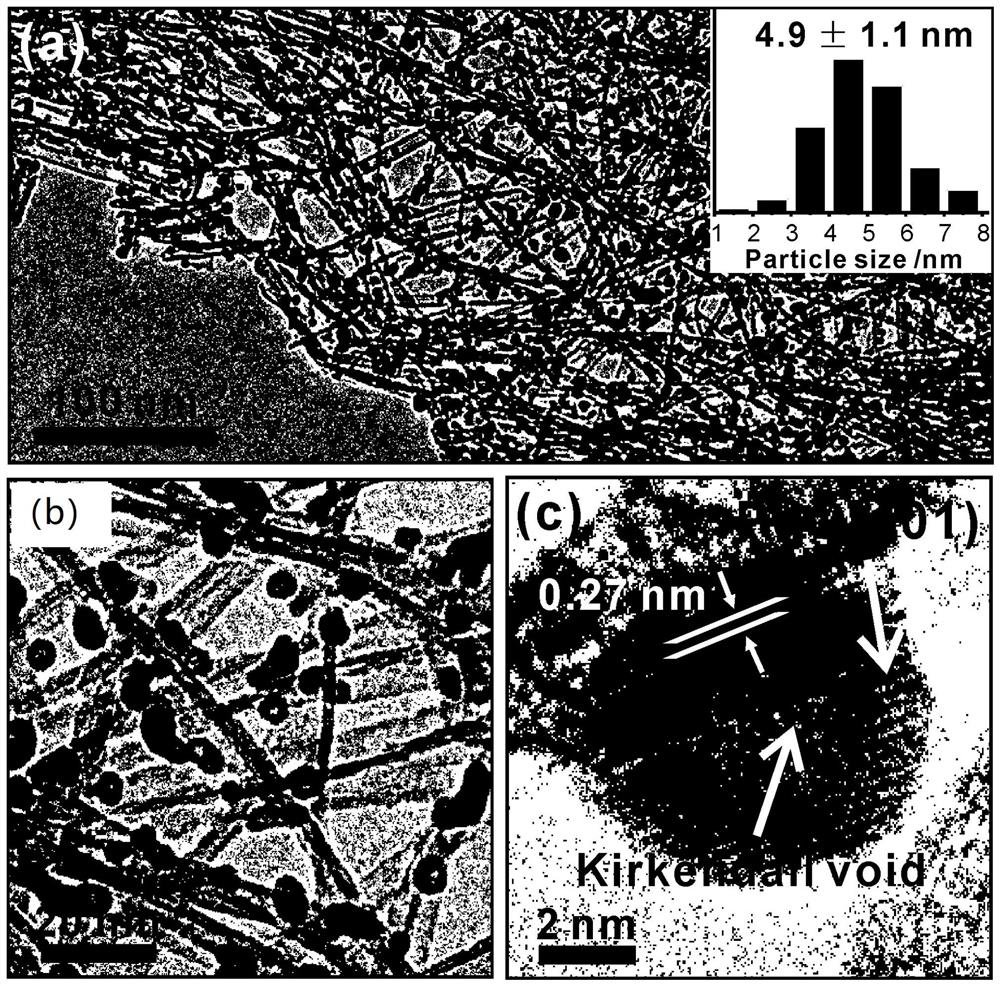

[0095] In this example, the chemical reduction method is used as an example to prepare Pd with a particle size of 5 nm. Weigh 150 mg of palladium diacetylacetonate into a 100 mL round-bottomed flask, measure 30 mL of oleylamine with a graduated cylinder, and stir in an oil bath at 60°C until the solution is clear; add 260 mg of borane-tert-butylamine complex (BTBC) was dissolved in 2 mL of oleylamine, then added dropwise to the flask, and the temperature was raised to 90°C for 1 h; after the solution was cooled to room temperature, 50 mL of absolute ethanol was added, centrifuged and washed with absolute ethanol for 2- After 3 times, dry it for later use.

[0096] TiO 2 Preparation of nanotubes: 0.6 g TiO 2 The powder and 60 mL NaOH (10 mol / L) solution were dispersed by ultrasonic wave for 30 min, and stirred in the dark for 1 h to mix well, then transferred to a stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner (100 mL), sealed, Place in a b...

Embodiment 2

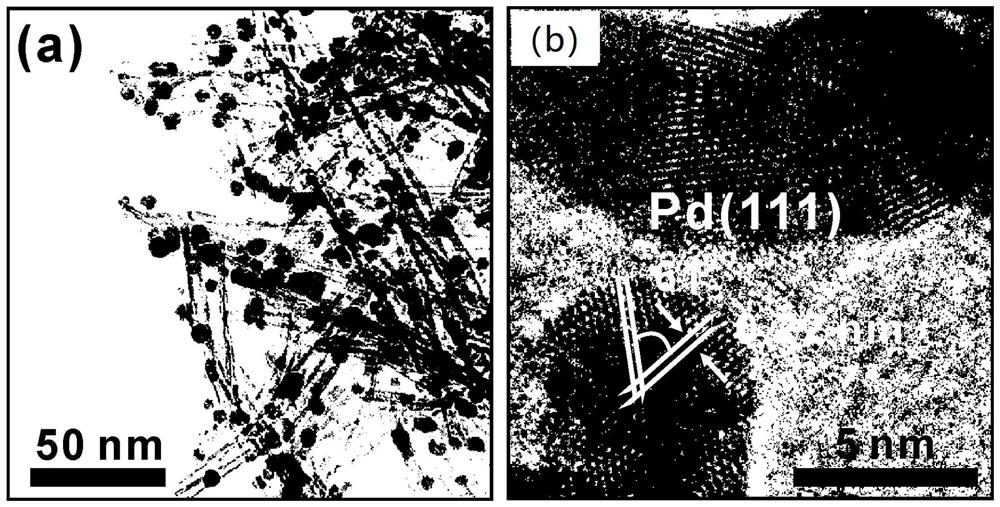

[0101] In this embodiment, the preparation of Pd nanoparticles by the photoreduction method is taken as an example. Prepare PdCl 2 aqueous solution, weigh 1 g of TiO 2 Nanoparticles (25 nm) were added to 10 mL of deionized aqueous solution, ultrasonically dispersed for 10 min, and PdCl was added dropwise during stirring 2 After the solution was added dropwise, stir for 30 min, irradiate the solution under a 300 W mercury lamp for 1 h, take out the centrifuged water, wash 2-3 times, and dry. By changing the precursor PdCl 2 The amount of Pd to adjust the TiO 2 The amount of loading on it ranges from 0.1wt% to 5wt%.

[0102] Other parts of this embodiment can refer to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com