Preparation method of foamed nickel based on a P-curved space structure

A space structure and nickel foam technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of foam metals that cannot provide mechanical properties, achieve excellent mechanical properties, simple process, and ensure mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

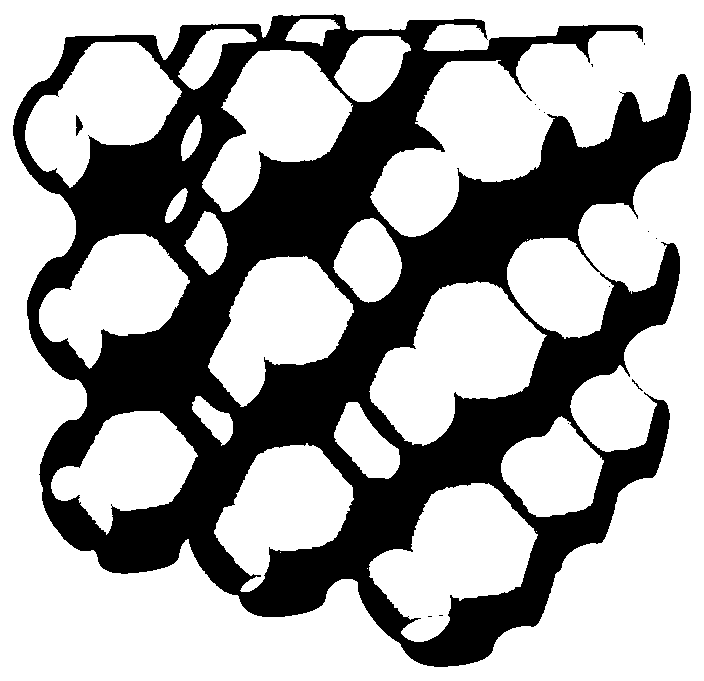

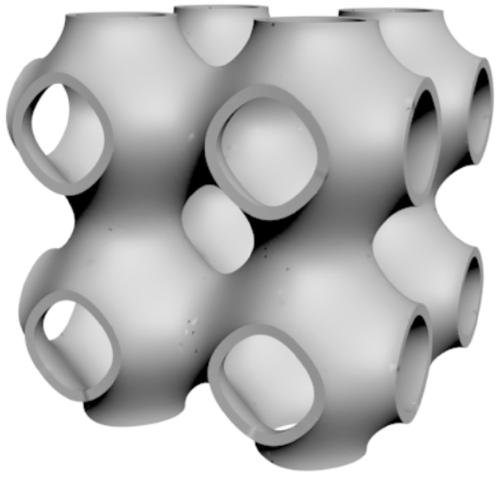

[0020] Step 1. Use 3D printing to prepare the PLA material into a P-curved spatial structure with a certain thickness, in which the period parameter is 2 and the surface thickness is 1mm, such as image 3 shown.

[0021] Step 2. Mix the refractory material and the binder in a certain proportion to prepare the coating slurry. The specific composition is: Al 2 o 3 , CaO and SiO 2 , the main components of the binder are water glass and silicon solution. Among them, the mass ratio of refractory material, water glass and silica sol is 85:10:5, and the main component of refractory material is Al 2 o 3 , and a small amount of CaO and SiO 2 , whose mass content is Al 2 o 3 : 95%, SiO 2 : 2%, CaO: 3%, add water and stir to adjust the Baume degree so that the Baume degree is 40.

[0022] Step 3. Use the P curved surface space structure obtained in step 1 and the coating slurry obtained in step 2 to prepare the shell, that is, first dip the P curved surface space structure with ...

Embodiment 2

[0027] Step 1. Use 3D printing to prepare the PLA material into a P-curved spatial structure with a certain thickness, in which the period parameter is 3 and the thickness of the curved surface is 1mm, such as image 3 Shown (instance two and instance one have the same spatial structure, the difference is that the surface thickness is different).

[0028] Step 2. Mix the refractory material and the binder in a certain proportion to prepare the coating slurry. The specific composition is: Al 2 o 3 , CaO and SiO 2 , the main components of the binder are water glass and silicon solution. Among them, the mass ratio of refractory material, water glass and silica sol is 85:10:5, and the main component of refractory material is Al 2 o 3 , and a small amount of CaO and SiO 2 , whose mass content is Al 2 o 3 : 95%, SiO 2 : 2%, CaO: 3%, add water and stir to adjust the Baume degree so that the Baume degree is 40.

[0029] Step 3. Use the P curved surface space structure obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com