A nanometer bimetallic layer back contact for undoped heterogeneous n-type single polished silicon solar cell and preparation method and application thereof are disclosed

A technology of silicon solar cells and double metal layers, which is applied in the field of solar cell technology, can solve the problems of poor repeatability, unsuitability for non-doped heterogeneous n-type single-throw silicon solar cells, and increase the complexity of the preparation process, achieving a balanced preparation Process and product performance, facilitate extraction and transport, improve energy conversion efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of nano-double metal layer back contact non-doped heterogeneous n-type single-throw silicon solar cell

[0032] Taking the back contact of Ag0.5Mg10 nanometer double metal layer as an example, Ag is a nanometer ultra-thin metal adhesion layer with a thickness of 0.5nm; Mg is an electron selective transport nanometer metal layer with a thickness of 10nm; the specific preparation process And the specific process of preparing non-doped heterogeneous n-type single-throw silicon solar cells is as follows:

[0033] (1) Soak a clean n-type single-sided polished silicon wafer (resistivity 0.05-0.1 Ω cm) in a hydrofluoric acid solution with a concentration of 10 M for 5 min to remove silicon oxide, and dry it;

[0034] (2) Coat the polished surface of the above-mentioned silicon wafer with an organic layer of PEDOT:PSS (PH1000), and anneal at 140°C for 10 minutes;

[0035] (3) Move the silicon wafer coated with the organic layer in step (2) to the vacuum c...

Embodiment 2

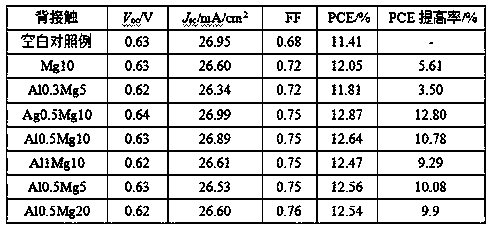

[0039] With reference to the preparation method in Example 1, the difference is to change the metal type of the nano-ultra-thin metal adhesion layer, applicable metals are Al, Ag and Au; change the thickness of the nano-ultra-thin metal adhesion layer, or electron selective transmission The thickness of the nano-metal magnesium layer, here are several representative back contacts, including Al0.5Mg10 nanometer double metal layer back contact, Al0.5Mg5 nanometer double metal layer back contact, Al0.5Mg20 nanometer double metal layer back contact and Au0.5Mg10 nanometer bimetallic layer back contact.

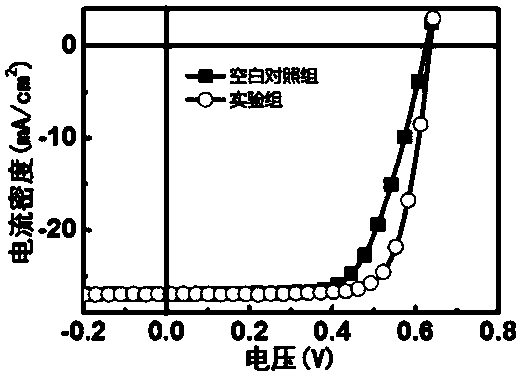

[0040] The representative nano-double metal layer back contact prepared above was prepared into a non-doped heterogeneous n-type single-throw silicon solar cell according to the method described in Example 1, and its energy conversion (PCE )performance.

[0041] Among them, the n-type single-polished silicon without nano-ultra-thin metal adhesion layer and electron selective tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com