Multi-component bone bonding material and a method of using the same

A kind of adhesive material and multi-component technology, applied in the field of medical materials, can solve the problems of surrounding tissue damage, inhibit the growth of new bone in the section, change the reaction ratio of components, etc., so as to facilitate the growth and regeneration of broken bones, overcome negative effects, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

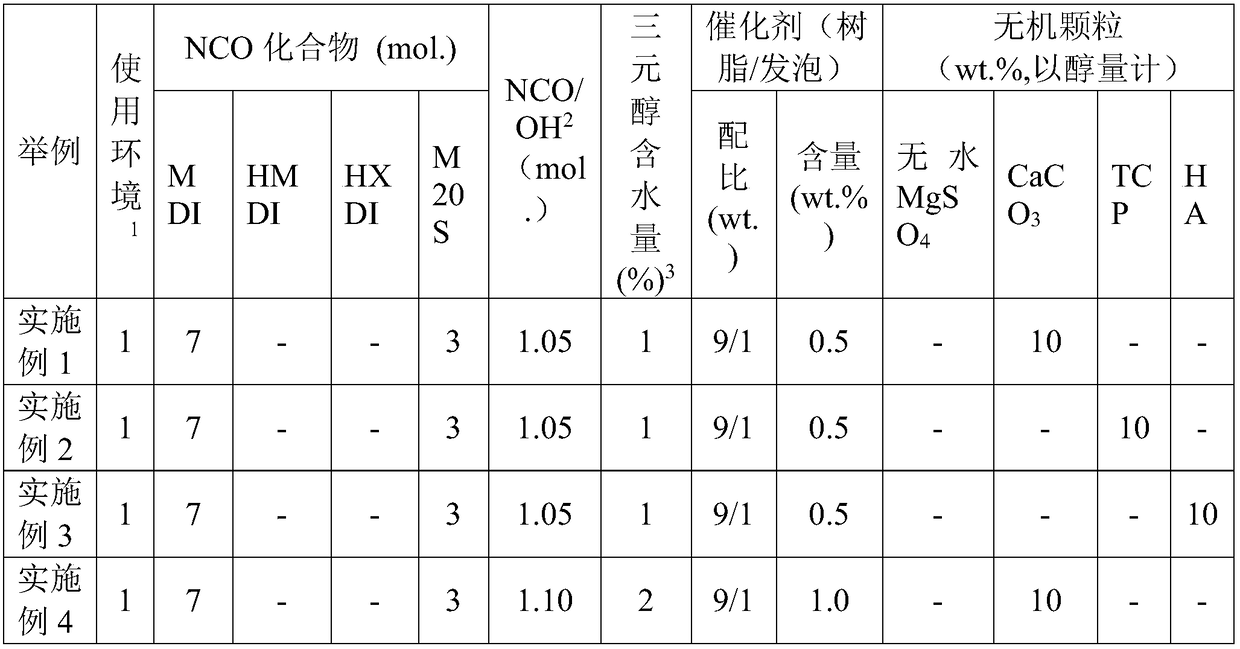

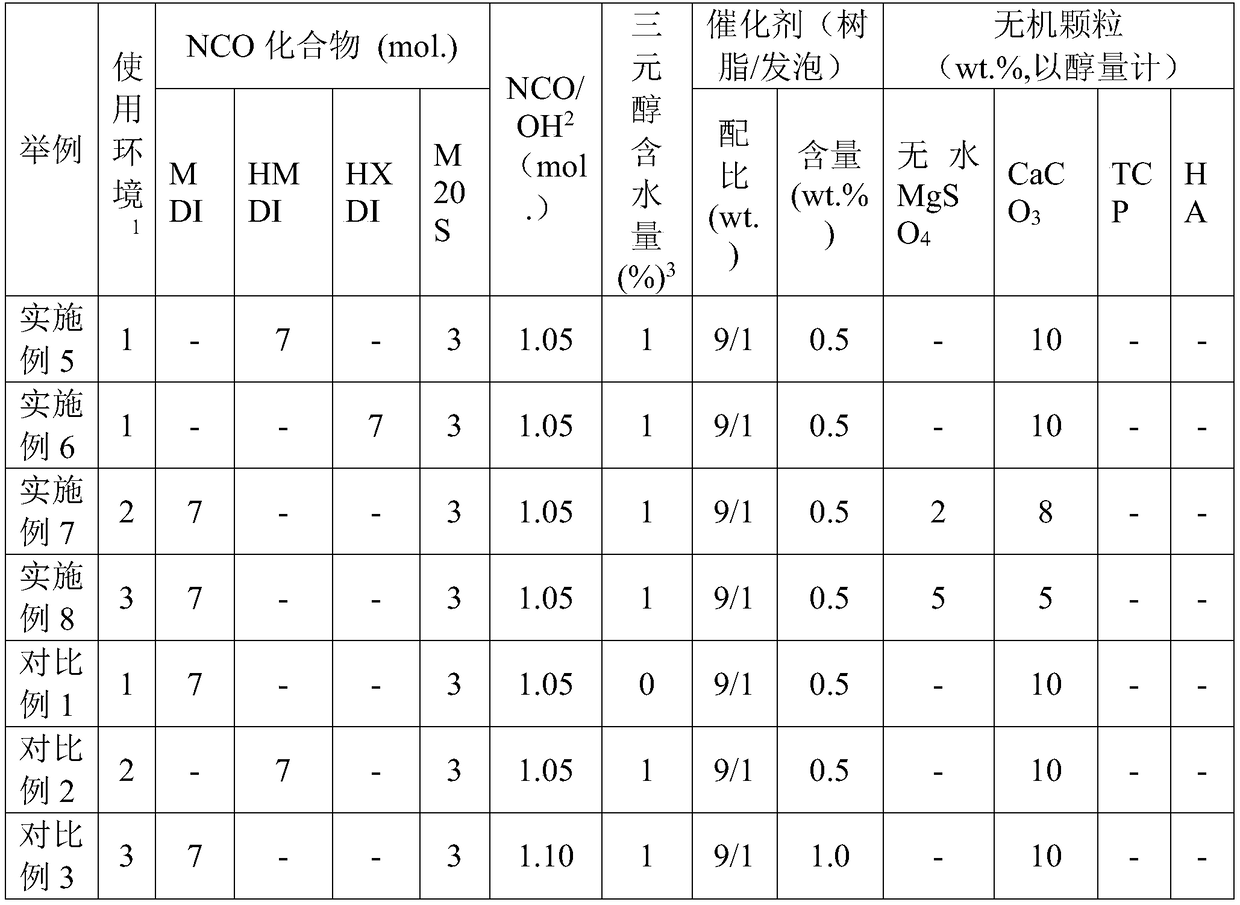

[0059] In a 150ml three-necked bottle equipped with nitrogen and a stirrer, heat up POLYCIN D290 (castor oil diol) and vacuumize and remove water for 2 hours, then add MDI with a molar ratio of 7 / 3 according to the molar ratio NCO / OH=1.05 (4,4'-diphenylmethane diisocyanate) and M20S (poly MDI), and then heated to 80 ° C, nitrogen protection reaction for 3 hours, to obtain light brown transparent polyurethane prepolymer. After the synthesis reaction of the polyurethane prepolymer is finished, samples are taken for titration, and the mass fraction of isocyanate is calculated.

[0060] Add 0.5wt.% catalyst F and pentamethyldiethylenetriamine (mass ratio 9 / 1) mixture to POLYCIN T400, and 1wt.% pure water, all calculated on the basis of POLYCINT400 weight, mix well and set aside to obtain ternary alcohol composition.

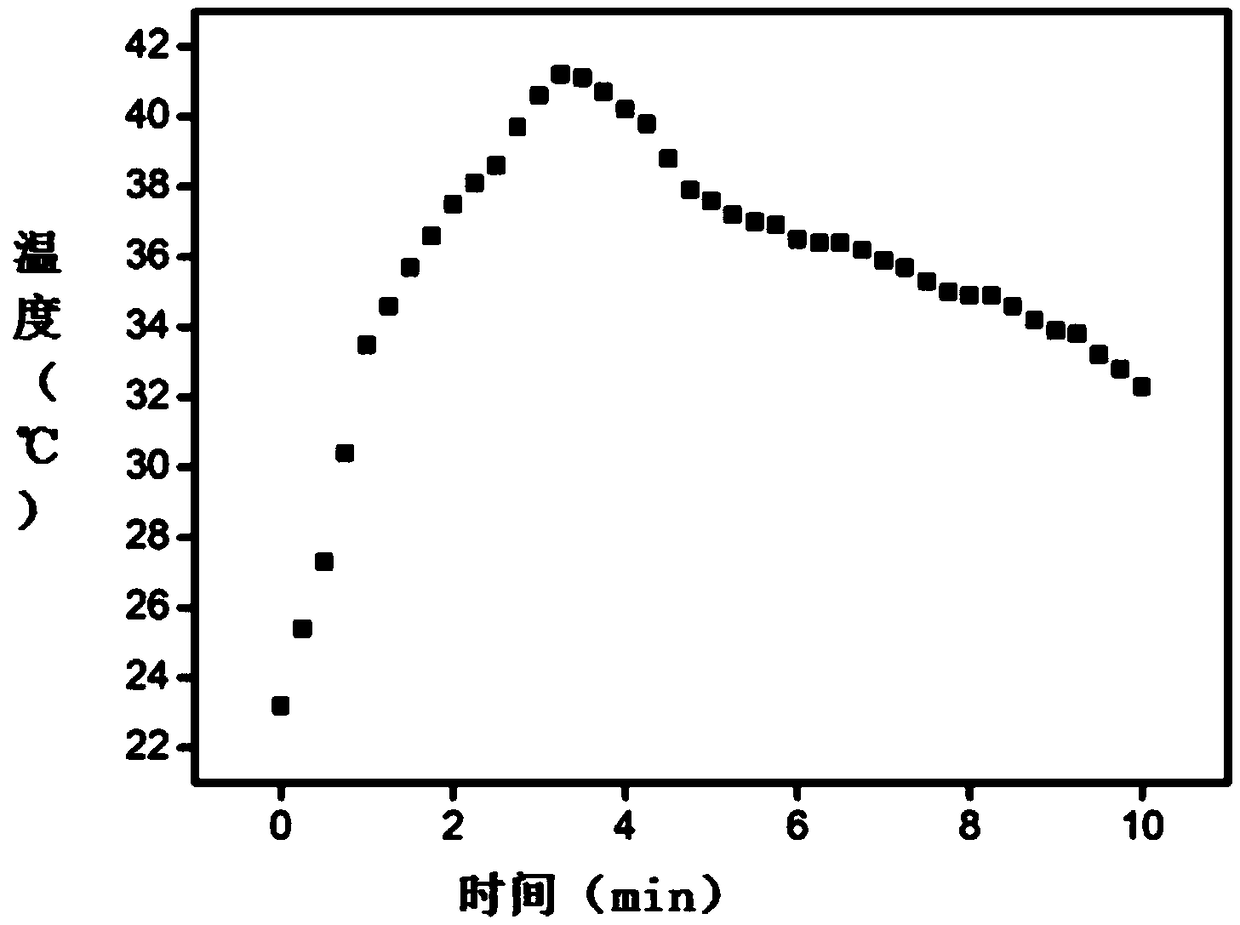

[0061] Test of bone adhesion performance in vitro: According to the formula of Example 1 in Table 1, add calcium carbonate powder, polyurethane prepolymer and trihy...

Embodiment 2

[0070] Compared with Example 1, except that calcium carbonate is replaced by β-tricalcium phosphate, other formulation processes remain unchanged. Likewise, in vitro bone adhesion experiments were performed in Environment 1.

Embodiment 3

[0072] Compared with Example 1, except that calcium carbonate is replaced by hydroxyapatite, other formulation processes remain unchanged. Likewise, in vitro bone adhesion experiments were performed in Environment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com