Preparation method and application of bismuth oxyiodide/titanium-based metal-organic framework composite

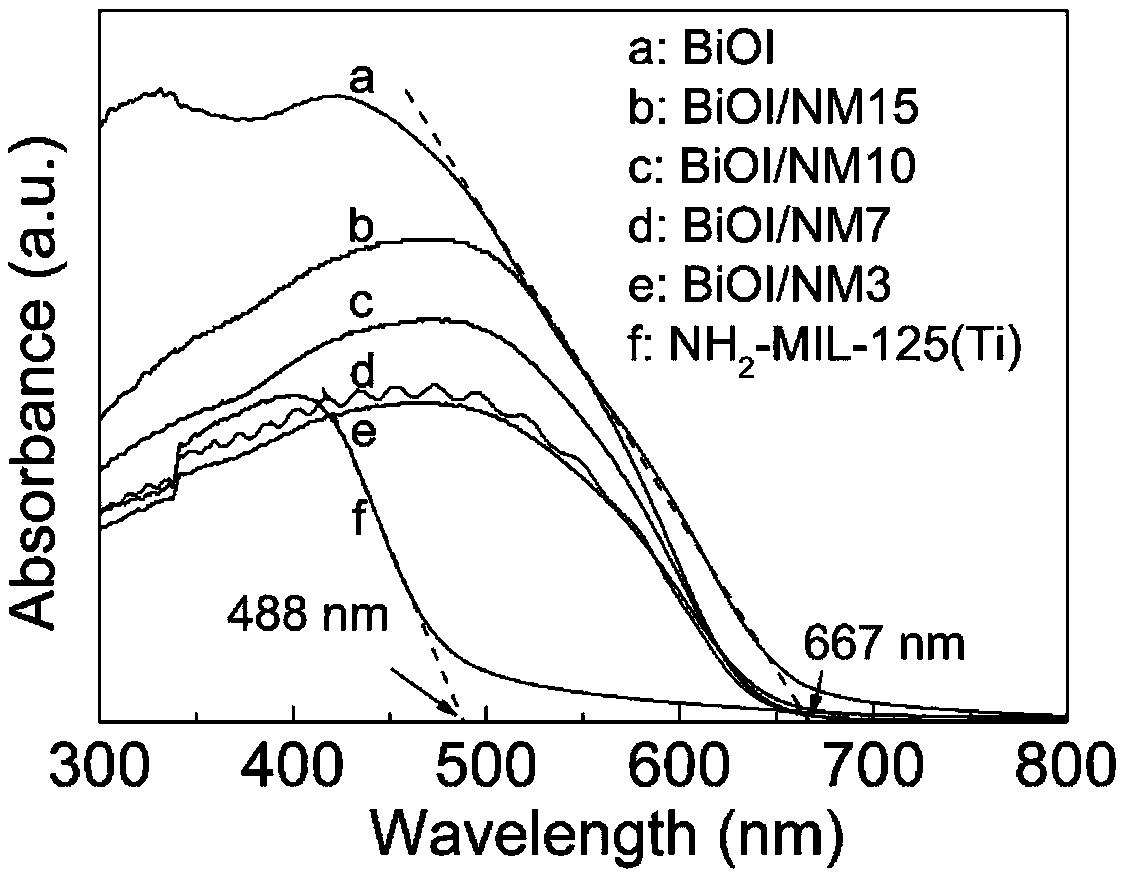

A technology of bismuth oxyiodide and composite materials, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problems of poor photocatalytic effect and low quantum efficiency, etc. To achieve the effect of reducing the probability of recombination, strong adsorption and enrichment ability, and enhancing the rate of charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a bismuth oxyiodide / titanium-based metal-organic framework composite material according to this embodiment, the method includes the following steps:

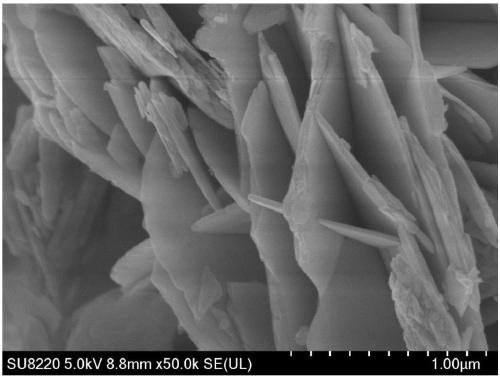

[0033] (1) NH 2 - Preparation of MIL-125(Ti)

[0034]Add 65ml of anhydrous N,N dimethylformamide (DMF) and 15ml of anhydrous methanol (MeOH) to the polytetrafluoroethylene liner (inner liner of the autoclave) respectively to form a mixed solution. After magnetic stirring for 5min, Add 3.81g (21mmol) 2-aminoterephthalic acid (H2ATA) and continue to stir for 20min, then add 4.78m1 tetrabutyl titanate (14mmol), continue to stir for 30min, remove the stirring bar, put the polytetrafluoroethylene liner in In a high-pressure reactor, tighten it, react at 150° C. for 72 hours, cool naturally, and filter to obtain crystals. Transfer the crystals to a beaker, disperse them in 70ml DMF and stir for 1 hour, wash off unreacted 2-aminoterephthalic acid and tetrabutyl titanate, filter and wash once with DMF; th...

Embodiment 2

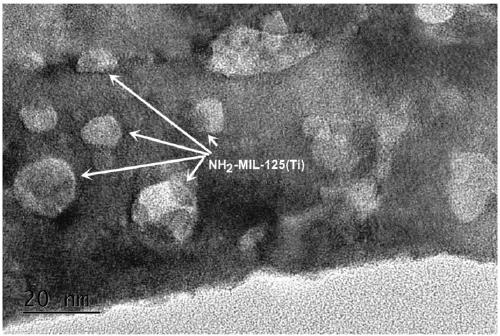

[0038] The preparation method of the bismuth oxyiodide / titanium-based metal-organic framework composite material of this embodiment is basically the same as that of Example 1, the only difference being that the NH in step (2) 2 - The amount of MIL-125 added is 0.053g; the sample obtained in this example is labeled as BiOI / NM7 or BiOI@NM7, that is, the amount of NH in the obtained photocatalytic material 2 - The content of MIL-125 in the composite sample is 7wt%.

Embodiment 3

[0040] The preparation method of the bismuth oxyiodide / titanium-based metal-organic framework composite material of this embodiment is basically the same as that of Example 1, the only difference being that the NH in step (2) 2 - The amount of MIL-125 added is 0.078g; the sample obtained in this example is labeled as BiOI / NM10 or BiOI@NM10, that is, the amount of NH in the obtained photocatalytic material 2 - The content of MIL-125 in the composite sample is 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com