Harmless treatment method for casting dust-removing ash

A technology of harmless treatment and treatment method, which is applied in the field of solid waste treatment and environmental protection regeneration, can solve the problems of natural gas consumption, achieve energy saving, wide application range, and reduce the consumption of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

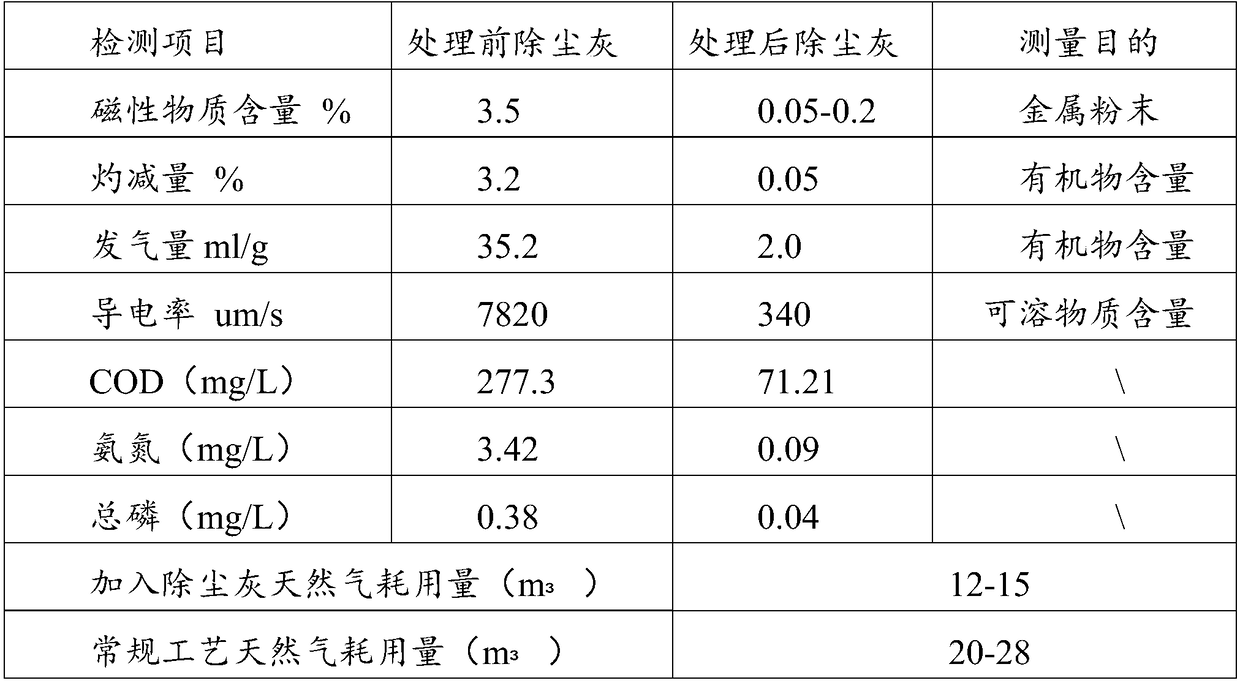

[0029] This embodiment provides a harmless treatment method and application of foundry dust removal. The specific treatment method includes the following steps:

[0030] (1) adopt magnetic separation device to remove the metal powder in the dedusting ash, obtain the dedusting ash after purification;

[0031] (2) Mix and roast the purified dedusting ash obtained in step (1) and granular foundry waste sand, the dedusting ash accounts for 5% of the weight of the foundry waste sand, and roast at 500° C. for 3 hours in a roasting furnace;

[0032] (3) After the roasting is completed, the regenerated sand and the processed dedusting ash are obtained, and the dedusting ash mixed in the regenerated sand is separated by negative pressure induced wind, and the dedusting ash is collected with a dedusting cloth bag;

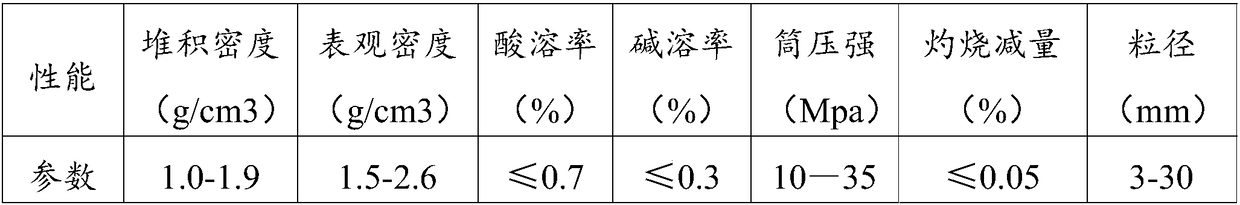

[0033] (4) Portland cement and clear water are added to step (3) gained dedusting ash, the Portland cement add-on is 10% of the dedusting ash weight after the described trea...

Embodiment 2

[0035] This embodiment provides a harmless treatment method and application of foundry dust removal. The specific treatment method includes the following steps:

[0036] (1) adopt magnetic separation device to remove the metal powder in the dedusting ash, obtain the dedusting ash after purification;

[0037] (2) Mix and roast the purified dedusting ash obtained in step (1) and granular foundry waste sand, the dedusting ash is 15% of the weight of the foundry waste sand, and roast at 700° C. for 8 hours in a roasting furnace;

[0038] (3) After the roasting is completed, the regenerated sand and the processed dedusting ash are obtained, and the dedusting ash mixed in the regenerated sand is separated by negative pressure induced wind, and the dedusting ash is collected with a dedusting cloth bag;

[0039] (4) Portland cement and clear water are added to step (3) gained dedusting ash, the Portland cement add-on is 40% of the dedusting ash weight after the described treatment, an...

Embodiment 3

[0041] This embodiment provides a harmless treatment method and application of foundry dust removal. The specific treatment method includes the following steps:

[0042] (1) adopt magnetic separation device to remove the metal powder in the dedusting ash, obtain the dedusting ash after purification;

[0043] (2) Mix and roast the dedusting ash obtained in step (1) and granular foundry waste sand, the dedusting ash is 10% of the weight of the foundry waste sand, and roast at 600° C. for 5 hours in a roasting furnace;

[0044] (3) After the roasting is completed, the regenerated sand and the processed dedusting ash are obtained, and the dedusting ash mixed in the regenerated sand is separated by negative pressure induced wind, and the dedusting ash is collected with a dedusting cloth bag;

[0045] (4) Portland cement and clear water are added to step (3) gained dedusting ash, the Portland cement add-on is 30% of the dedusting ash weight after the described treatment, and the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com