Flame-retardant insulating cable material and preparation method thereof

A technology for insulated cables and flame retardants, applied in rubber insulators, organic insulators, etc., can solve the problems affecting the strength of cable materials and large dosage, and achieve the effects of good strength and toughness, excellent flame retardant performance, and enhanced flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

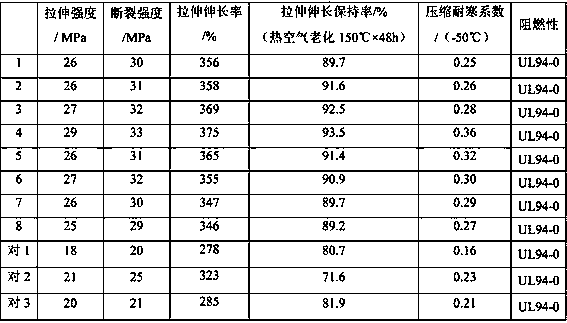

Examples

Embodiment 1

[0025] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0026] 25 parts of nitrile rubber, 25 parts of polybutadiene rubber, 15 parts of vinyl chloride-acrylate copolymer, 5 parts of polyimide fiber, 15 parts of flame retardant, 8 parts of filler, 3 parts of anti-aging agent, softener 10-23 parts, 1 part of accelerator and 2 parts of crosslinking agent.

[0027] The flame retardant is bisphenol A bis(diphenyl phosphate) BDP.

[0028] The filler is carbon black N330.

[0029] The antioxidant is OD.

[0030] Described softening agent is paraffin oil.

[0031] The accelerator is accelerator M.

[0032] The crosslinking agent is dicumyl peroxide.

[0033] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0034] (1) Add nitrile rubber, polybutadiene rubber, vinyl chloride-acrylate copolymer and polyimide fiber into a high-speed mixer, and mix for 5 mi...

Embodiment 2

[0038] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0039] 28 parts of nitrile rubber, 28 parts of polybutadiene rubber, 16 parts of vinyl chloride-acrylate copolymer, 6 parts of polyimide fiber, 16 parts of flame retardant, 9 parts of filler, 4 parts of anti-aging agent, softener 12 parts, 1.2 parts of accelerator and 2 parts of crosslinking agent.

[0040] The flame retardant is polyphenyl resorcinol phosphate PRPP.

[0041] The filler is carbon black N550.

[0042] The anti-aging agent is MB.

[0043] Described softening agent is naphthenic oil.

[0044] The accelerator is accelerator DM.

[0045] The crosslinking agent is benzoyl peroxide.

[0046] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0047] (1) Add nitrile rubber, polybutadiene rubber, vinyl chloride-acrylate copolymer and polyimide fiber into a high-speed mixer, and mix for...

Embodiment 3

[0051] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0052]30 parts of nitrile rubber, 29 parts of polybutadiene rubber, 18 parts of vinyl chloride-acrylate copolymer, 7 parts of polyimide fiber, 18 parts of flame retardant, 9 parts of filler, 5 parts of anti-aging agent, softener 14 parts, 1.5 parts of accelerator and 3 parts of crosslinking agent.

[0053] The flame retardant is hydroquinone bis(diphenyl phosphate) HDP.

[0054] The filler is carbon black N660.

[0055] The anti-aging agent is 4010NA.

[0056] Described softening agent is hydroxyl silicone oil.

[0057] The accelerator is accelerator TBTD.

[0058] The crosslinking agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane.

[0059] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0060] (1) Add nitrile rubber, polybutadiene rubber, vinyl chloride-acrylate copolymer and polyimid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com