Apparatus and method for continuously preparing hollow fiber composite membrane

A fiber composite and hollow technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems that hollow fiber composite membranes cannot be produced continuously in industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

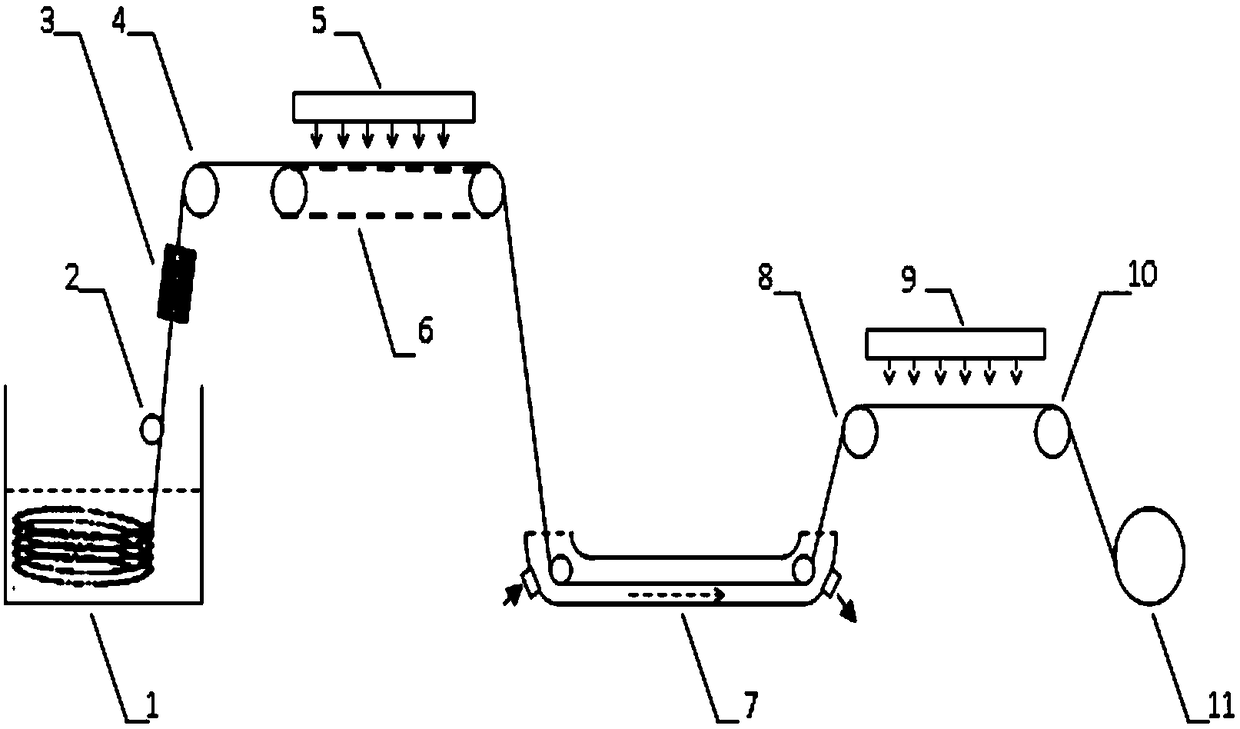

Method used

Image

Examples

Embodiment 1

[0016] Soak the polysulfone hollow fiber membrane in the aqueous phase solution containing 1.0% piperazine and other additives for a period of time, and then enter the hot air device (at a temperature of 10°C and a wind speed of 10m / h) along with the conveying device to dry on-line for about 10s, and then The belt with a speed of 1m / h is conveyed into the pressure-resistant glass tube, and the flow speed of the organic solution is 1m / h; the trimesoyl chloride contained in the organic solution and piperazine undergo interfacial polymerization to form a polyamide coating. The hollow fiber composite membrane is sent to the post-processing device (the temperature of the hot air circulation drying device is 10°C and the wind speed is 10m / h) by the power guide roller for curing treatment; then, the hollow fiber composite membrane is rolled into a large roll by the winding device for standby. The obtained hollow fiber composite membrane is 1500ppm MgSO under 25 ℃, 0.6MPa pressure 4 d...

Embodiment 2

[0018] Soak the polyvinylidene fluoride hollow fiber membrane in an aqueous solution containing 1.0% piperazine and other additives for a period of time, and then enter the hot air device (at a temperature of 50°C and a wind speed of 500m / h) along with the conveying device for online drying for about 5s. It is conveyed into a pressure-resistant glass tube by a belt with a conveying speed of 50m / h, and the flow speed of the organic solution is 50m / h; the trimesoyl chloride contained in the organic solution undergoes interfacial polymerization with piperazine to form a polyamide coating. The hollow fiber composite membrane is sent to the post-processing device (the temperature of the hot air circulation drying device is 100°C and the wind speed is 1500m / h) by the power guide roller for curing treatment; then, the hollow fiber composite membrane is rolled into a large roll by the winding device for standby. The obtained hollow fiber composite membrane is 1500ppm MgSO under 25 ℃, 0...

Embodiment 3

[0020] Soak the polyethersulfone hollow fiber membrane in an aqueous solution containing 1.0% polyethyleneimine and other additives for a period of time, and then enter the hot air device (at a temperature of 100°C and at a wind speed of 1500m / h) with the conveying device for online drying for about 2s , is transported to the pressure-resistant glass tube by a belt with a transmission speed of 100m / h, and the flow speed of the organic solution is 100m / h; the trimesoyl chloride contained in the organic solution and polyethyleneimine undergo interfacial polymerization to form branched polyamide imide coating. The hollow fiber composite membrane is sent to the post-processing device (chemical treatment device) by the power guide roller for curing treatment; subsequently, the hollow fiber composite membrane is rolled into a large roll by the winding device for standby. The obtained hollow fiber composite membrane is 1500ppm MgSO under 25 ℃, 0.6MPa pressure 4 desalination experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com