A kind of porous manganese series lithium ion sieve adsorbent and preparation method thereof

A lithium ion and adsorbent technology, which is applied in the field of porous manganese-based lithium ion sieve adsorbent and its preparation, can solve the problems of particle uniformity and dispersibility, large energy consumption and the like without using an effective method, and achieves reduction of reaction steps and preparation. The effect of cost, good quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] As an aspect of the technical solution of the present invention, what it relates to is a kind of preparation method of porous manganese series lithium ion sieve adsorbent, comprising the following steps:

[0029] (1) adding manganese source and lithium source into water, stirring to obtain the first mixed solution;

[0030] (2) adding an organic polyalcohol compound into the first mixed solution, and stirring to obtain a second mixed solution;

[0031] (3) Place the second mixed solution in a microwave reactor, react at 120-200° C. for 10-120 minutes, and then perform solid-liquid separation on the solid and liquid in the second mixed solution to obtain LiMnO 2 particles;

[0032] (4) the resulting LiMnO 2 The particles were calcined at 450-600°C for 3-8 hours to obtain Li 1.6 mn 1.6 o 4 Porous manganese-based lithium ion sieve adsorbent.

[0033] In some embodiments, the manganese source includes any one or two or more of potassium permanganate, sodium permangana...

Embodiment 1

[0049] (1) Potassium permanganate and anhydrous lithium hydroxide were added into deionized water at a ratio of 0.15:1, and magnetically stirred to obtain a first mixed solution.

[0050] (2) Add glycerol to the first mixed solution, the ratio of glycerol to potassium permanganate is 5:1, mix and magnetically stir to obtain the second mixed solution.

[0051] (3) Put the second mixed liquid into a microwave reactor at a temperature of 120° C. and a reaction time of 10 minutes. After the reaction is completed, the solid and liquid mixtures are subjected to solid-liquid separation to obtain a solid, which is washed and dried to obtain pure LiMnO 2 particles.

[0052] (4) LiMnO will be obtained 2 Calcined at 450°C for 8 hours to obtain Li 1.6 mn 1.6 o 4 Lithium ion adsorbent.

[0053] (5) Li will be obtained 1.6 mn 1.6 o 4 The lithium-ion adsorbent was exchanged and washed three times with deionized water and ethanol.

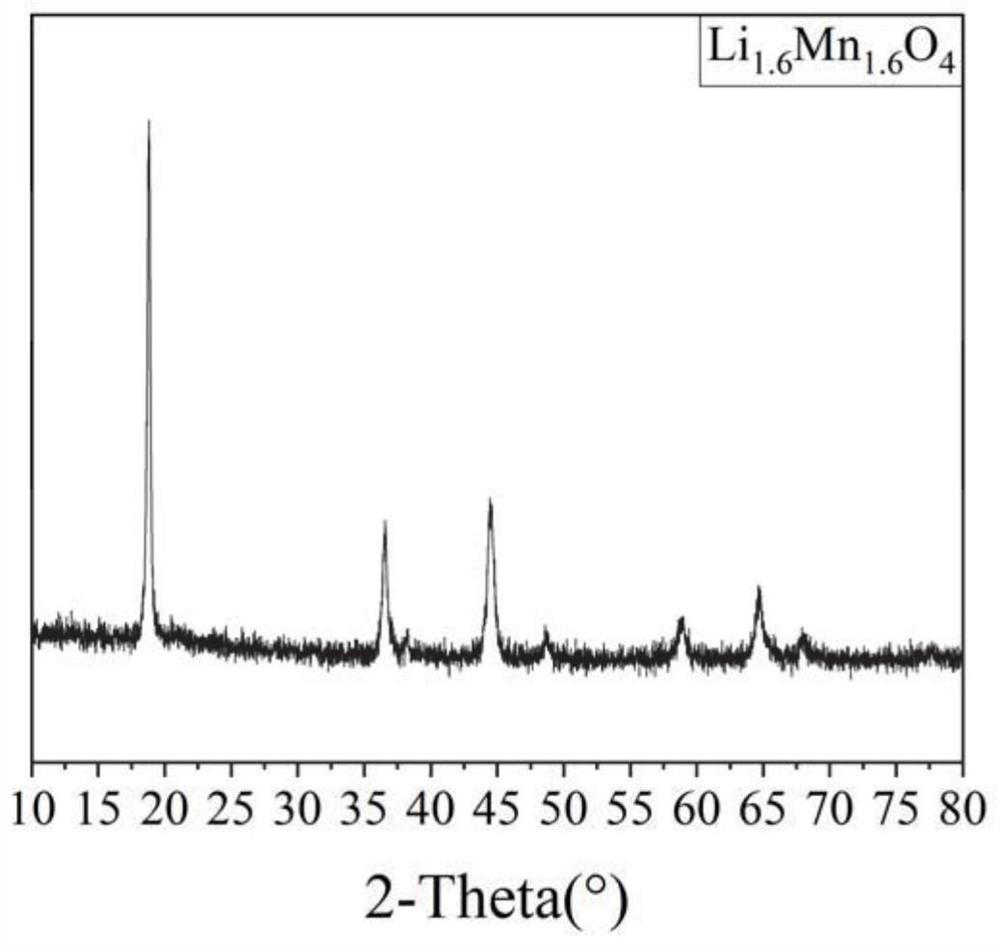

[0054] The XRD diffraction pattern of the porous m...

Embodiment 2

[0057] (1) Potassium permanganate and anhydrous lithium hydroxide were added into deionized water at a ratio of 0.8:1, and magnetically stirred to obtain a first mixed solution.

[0058] (2) Add glycerol to the first mixed solution, the ratio of glycerol to potassium permanganate is 50:1, mix and magnetically stir to obtain the second mixed solution.

[0059] (3) Put the second mixed solution into a microwave reactor at a temperature of 200° C. and a reaction time of 2 hours. After the reaction is completed, the solid and liquid mixtures are subjected to solid-liquid separation, and the solids obtained are washed and dried to obtain pure LiMnO 2 particles.

[0060] (4) LiMnO will be obtained 2 Calcined at 600°C for 8 hours to obtain Li 1.6 mn 1.6 o 4 Lithium ion adsorbent.

[0061] (5) Li will be obtained 1.6 mn 1.6 o 4 The lithium-ion adsorbent was exchanged and washed three times with deionized water and ethanol.

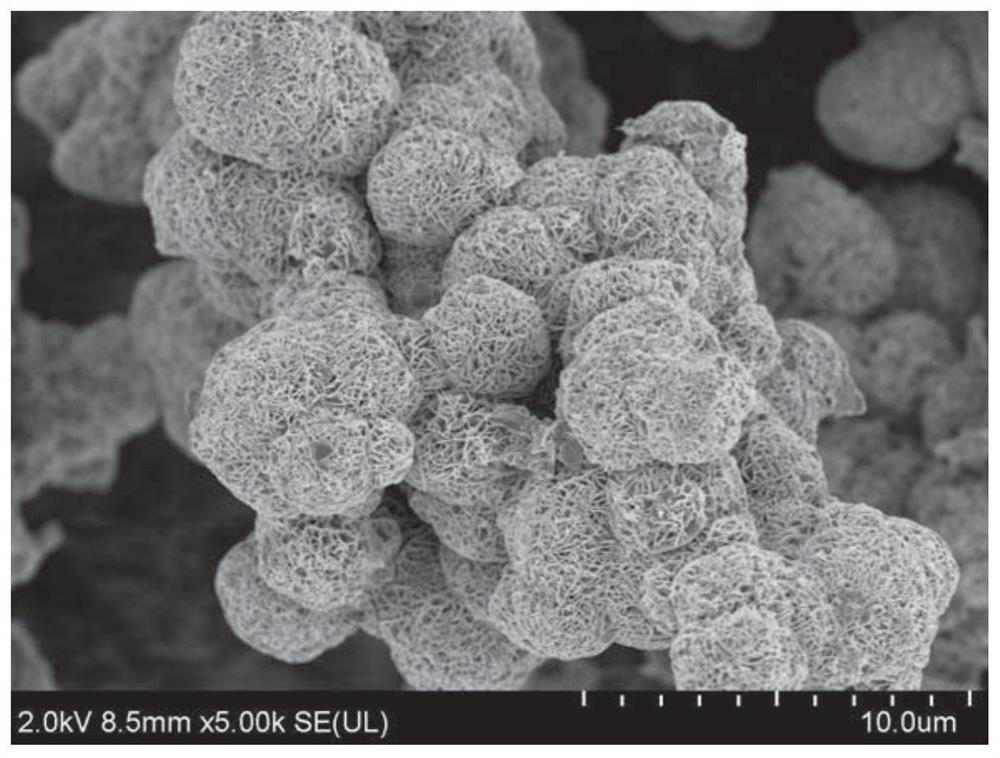

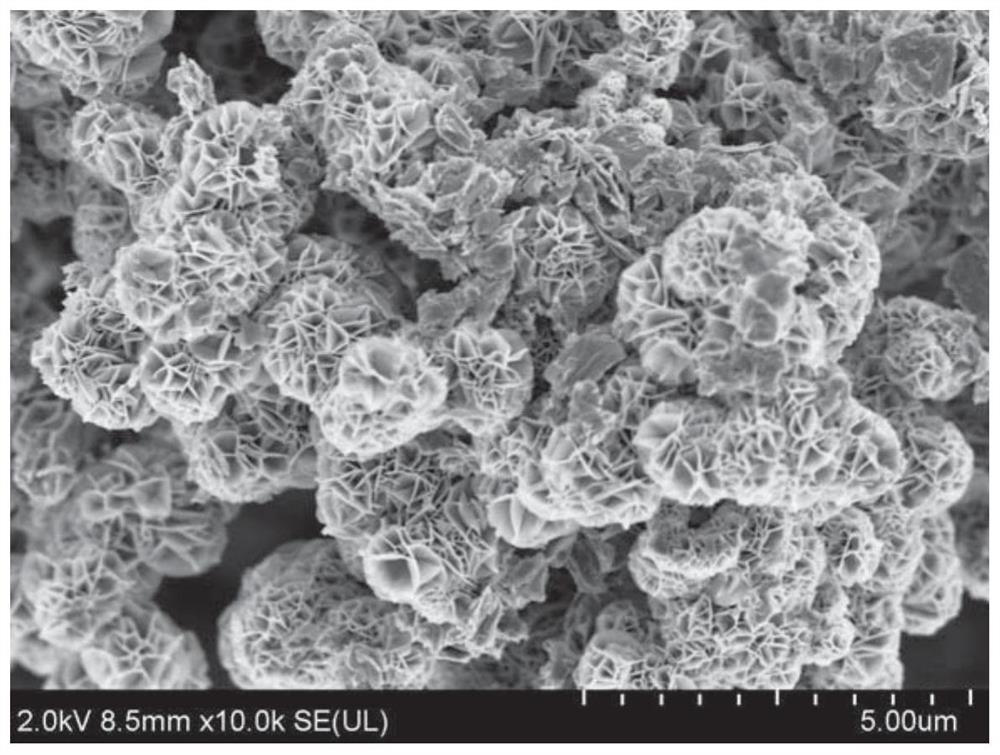

[0062] The SEM scanning picture of the porous mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com