Device and method for quickly making fertilizer from kitchen waste

A kitchen waste, fast technology, applied in the field of kitchen waste rapid fertilizer making device, can solve the problems of inability to effectively deal with kitchen waste, shorten the biological treatment cycle, shorten the composting reaction cycle, etc., to achieve complete resource utilization of composting, The effect of avoiding secondary pollution and treatment costs, and avoiding the waste of exhaust energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

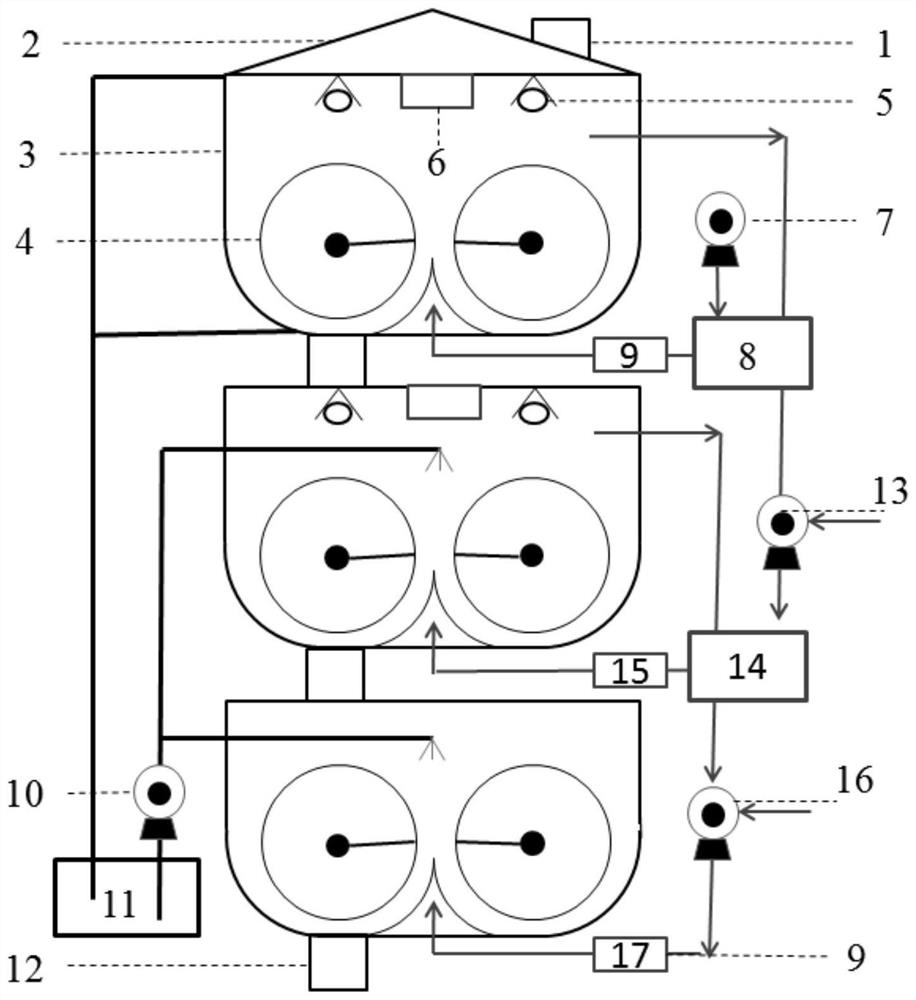

[0026] A device for quickly making fertilizer from kitchen waste, which includes a three-stage main reactor, an infrared radiation heat preservation unit, a hot air supply unit, and a condensed water leachate return unit.

[0027] The three-stage main reactor includes three reactor main bodies 3, and the three reactor main bodies 3 are arranged in parallel in the vertical direction, and are respectively a primary reactor, a secondary reactor and a tertiary reactor from top to bottom. , the discharge ports 12 of the primary and secondary reactors are respectively connected with the feed ports 1 of the secondary and tertiary reactors; the main body 3 of each reactor is covered with thermal insulation material and equipped with a double-helix material mixing propulsion The device 4 is used to fully mix the kitchen waste in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com