Method for preparing solid red-to-yellow-up conversion copolymer system

一种共聚物、固态的技术,应用在固态红-转-黄上转换共聚物体系的制备领域,能够解决转换效率低、需要除氧等问题,达到高效转换效率、解决固态上转换效率低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

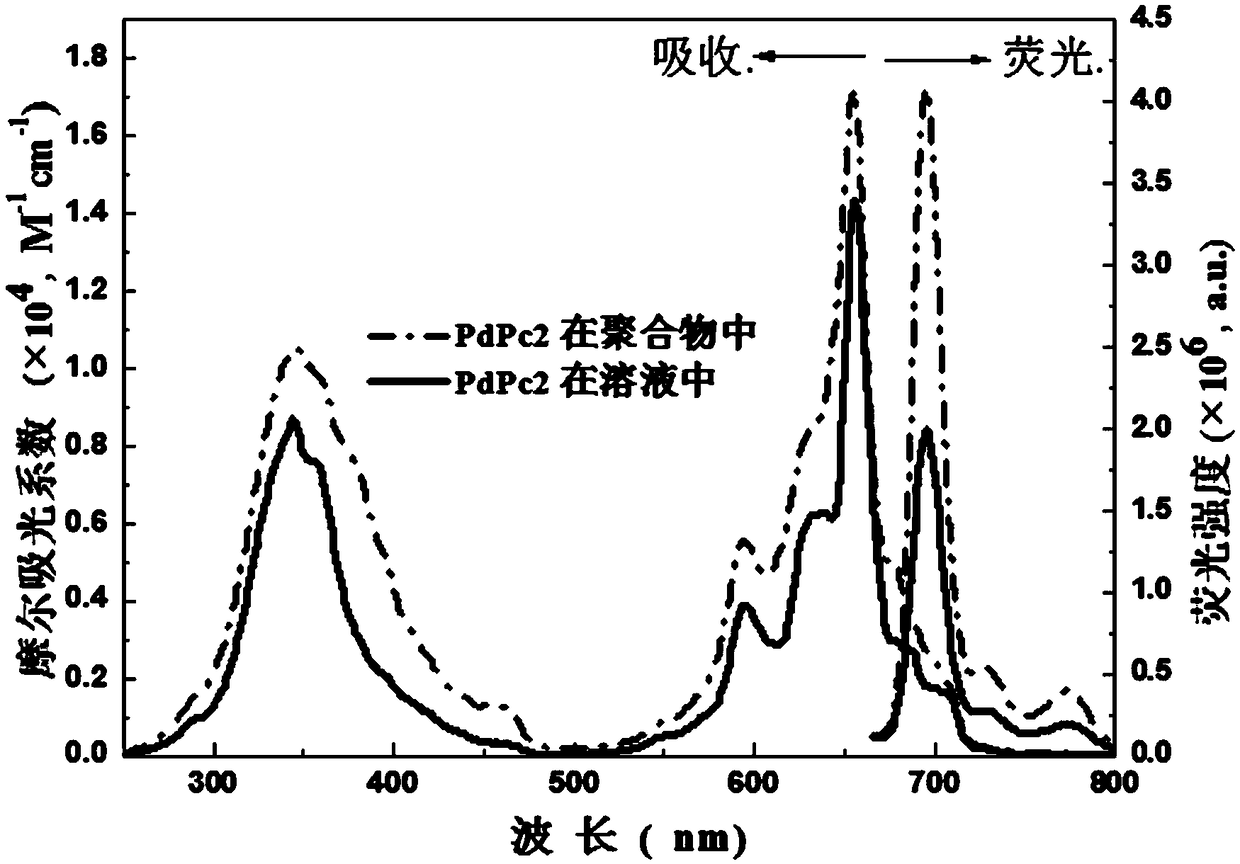

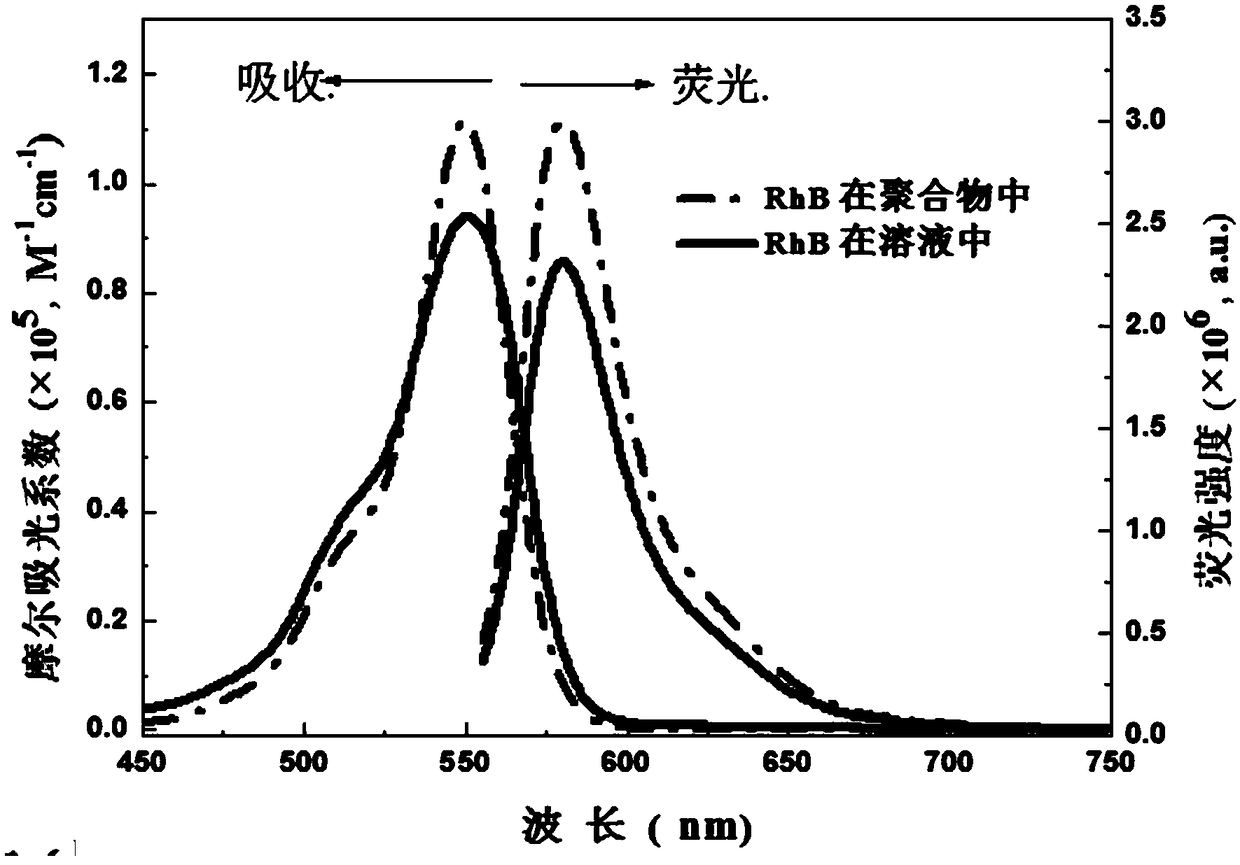

[0055] (1) Two-component upconversion solution (PdPc 2 / luminescent agent) configuration: the sensitizer (PdPc 2 ) Mother liquor (concentration is 4×10 -5 mol / L) and luminescent agent mother solution (concentration is 1×10 -2 mol / L) are mixed according to a certain molar ratio and degassed to obtain a two-component solution of sensitizer / luminescent agent. The solvents involved in all the above solutions are spectrally pure n-propanol / ethylene glycol (v / v, 1 / 2).

[0056] The luminescent agent can be any one of the following rhodamine derivatives:

[0057]

[0058] (2) Preparation of solid-state up-conversion copolymer system: In a nitrogen atmosphere, 2-hydroxyethylene methyl acrylate (HEMA) and 3-(methacryloyloxy)propyltrimethoxysilane (TMSPMA) Mix according to 1:1 (mass ratio), add 0.5% (mass ratio) of azobisisobutyronitrile as an initiator, and then add a two-component solution (the molar ratio of sensitizer and luminescent agent is 1:3000), Vacuumize (30 min) afte...

Embodiment 2

[0079] According to the preparation method of Example 1, wherein HEMA and TMSPMA are mixed at 1:2 (mass ratio), 0.5% (mass ratio) of azobisisobutyronitrile is added as an initiator, and then a two-component solution (sensitizer The molar ratio of the luminescent agent and the luminescent agent is 1:3000) to prepare a solid-state up-conversion copolymer system. When the luminescent agent is RhB, RhBS, and Rh6G, the up-conversion efficiencies are 9.6%, 12.3%, and 2.9%, respectively. Correspondingly, under other conditions being the same, the upconversion efficiencies of the luminescent agents RhB, RhBS and Rh6G in the solution state are: 6.8%, 8.7% and 2.2%, respectively. Comparing Example 1 with Example 2, it can be seen that the ratio of the two polymer monomers has little influence on the up-conversion efficiency of the solid-state up-conversion system; meanwhile, under the same conditions, the up-conversion efficiency of the solid-state up-conversion system is greater than U...

Embodiment 3

[0081] According to the preparation method of Example 1, the solvents involved in the sensitizer and luminescent agent solutions are both spectroscopically pure propanol / ethylene glycol (v / v, 1 / 6); HEMA and TMSPMA are 1:4 (mass ratio ) mixed, adding 0.5% (mass ratio) of azobisisobutyronitrile as an initiator, and then adding a two-component solution (the molar ratio of sensitizer and luminescent agent is 1:3000) to prepare a solid-state up-conversion copolymer system , when the luminescent agent is RhB, RhBS, and Rh6G, the up-conversion efficiency is 9.4%, 11.8%, and 2.6%, respectively. Correspondingly, under other conditions being the same, the upconversion efficiencies of the luminescent agents RhB, RhBS, and Rh6G in the solution state were: 6.4%, 8.3%, and 1.9%, respectively. Comparing Example 1 with Example 3, it can be seen that as the ratio of solvent n-propanol / ethylene glycol changes, the up-conversion efficiency of the solution state also decreases; meanwhile, under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com