Preparation method of anti-ultraviolet environment-friendly wallboard

An anti-ultraviolet and environmentally friendly technology, applied in the field of decorative materials, can solve problems such as fading, affecting the service life of wallboards, and easy cracking, and achieve the effects of good fastness, extended service life, good anti-ultraviolet and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

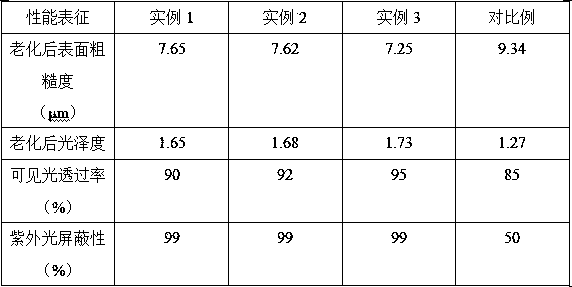

Examples

Embodiment Construction

[0020] In terms of weight fraction, weigh 1 to 10 parts of zinc oxide, 20 to 50 parts of deionized water, 1 to 4 parts of 1% sodium dodecylbenzenesulfonate and 10 to 16 parts of titanium sulfate solution, and Mix zinc oxide with deionized water, add 1% sodium dodecylbenzene sulfonate dropwise, and disperse ultrasonically for 5-10 minutes at a power of 200-300W to obtain a dispersion, add titanium sulfate solution dropwise, at a temperature of 60-80 Stir and react at ℃ for 5-7 hours, and adjust the pH of the system to 9-10 with ammonia solution to obtain a complex emulsion, which is neutral after washing with deionized water, and dried in an oven at 80-100 ℃ to constant weight to obtain a mixture , calcined at a temperature of 600-800°C for 2-4 hours, cooled to room temperature to obtain additives; the bamboo pulp cardboard was crushed at a beating degree of 15-18°SR with a hydraulic pulper, and screened, sand-removed and purified , to obtain fiber slurry; in parts by weight, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com