A kind of salicamide zinc chelate and preparation method thereof

A technology of zinc salicylamide and chelate, which is applied in the field of zinc salicylamide chelate and its preparation, can solve problems such as high toxicity and marine environmental pollution, and achieve easy-to-obtain raw materials, easy-to-control reaction conditions, and obvious adhesion and growth The effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

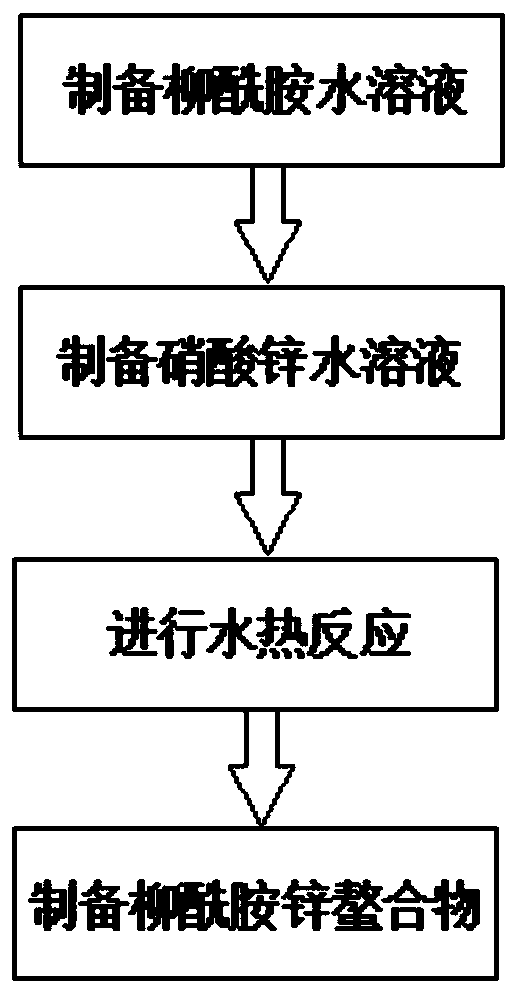

[0018] The technical process of the preparation method of the salicylamide zinc chelate involved in this embodiment is as follows: in the reaction flask, add 2.49 g of salicylamide, then add 20 ml of distilled water, stir magnetically, and heat the water bath to 50 ° C to obtain an aqueous solution of salicylamide; Dissolve g zinc nitrate hexahydrate in 20ml of distilled water, slowly drop the aqueous solution of zinc nitrate into the aqueous solution of salamide for hydrothermal reaction, the reaction temperature is 60°C, and the reaction time is 2h. After the hydrothermal reaction is completed, react again at room temperature Add 50ml of absolute ethanol in the bottle, shake to obtain a yellow precipitate, use a vacuum filter to carry out suction filtration, rinse with suction after 3 times, and after drying, prepare the following image 3 The salicylamide zinc chelate shown.

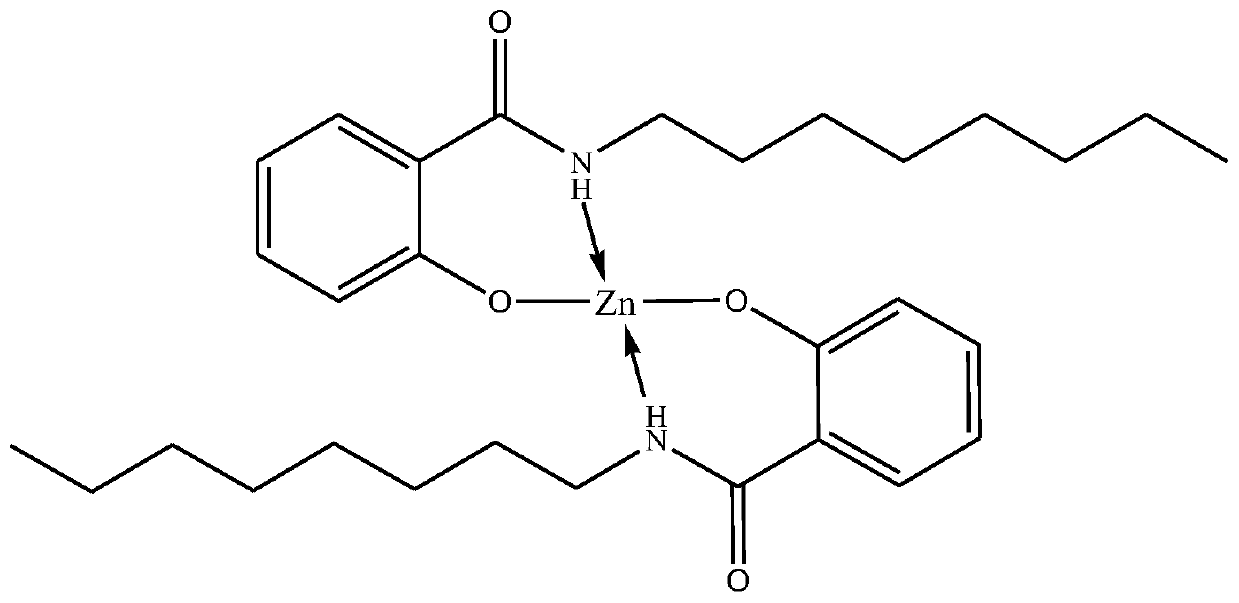

[0019] The salicylamide zinc chelate involved in this example is a zinc-containing benzamide compo...

Embodiment 2

[0021] This embodiment relates to the infrared characterization of the zinc salicylamide chelate, and the zinc salicylamide chelate prepared in Example 1 is tested by red light spectrum, and the results are as follows Figure 4 Shown, consistent with the molecular structure formula of embodiment 1: wherein 3407cm -1 N-H stretching vibration absorption peak, 3000-2800cm -1 is saturated C-H stretching vibration, 1645cm -1 It is the C=O stretching vibration absorption peak of amide, 1585cm -1 、1540cm -1 and 1442cm -1 Vibration for the benzene ring skeleton, 740cm -1 The strong absorption peak at is the C-H out-of-plane bending vibration of the benzene substituent, that is, the ortho-position double substitution.

Embodiment 3

[0023] This example relates to the antifouling performance test of the salicylamide zinc chelate: take the salicylamide zinc chelate prepared in Example 1 and dissolve it in water to prepare a gradient concentration solution with a concentration of 0.01-10 μg / mL; add the gradient concentration solution to to a concentration of 10 5 In the aqueous solution of small navicula diatoms / mL, the temperature was 25°C, the light intensity was 1900lux, and the light-dark cycle was 12h: 12h, and the attached diatoms were counted. 50% inhibitory concentration EC 500.3 μg / mL; the gradient concentration solution was added to the mussel test plate, 10 mussels were placed in each plate, and after 24 hours, the number of silk attached to the silk was counted, and the adhesion of the zinc salamide chelate to the silk of the mussel was calculated. The half maximal inhibitory concentration EC 50 It was 0.25 μg / mL; the gradient concentration solution was added to the barnacle larvae test cup, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com