Protective paint for ship anchor chains, and preparation method thereof

A protective paint and anchor chain technology, applied in anti-corrosion coatings, coatings, alginic acid coatings, etc., can solve the problems of biohazard and many chemical components, and achieve low cost, high environmental friendliness and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

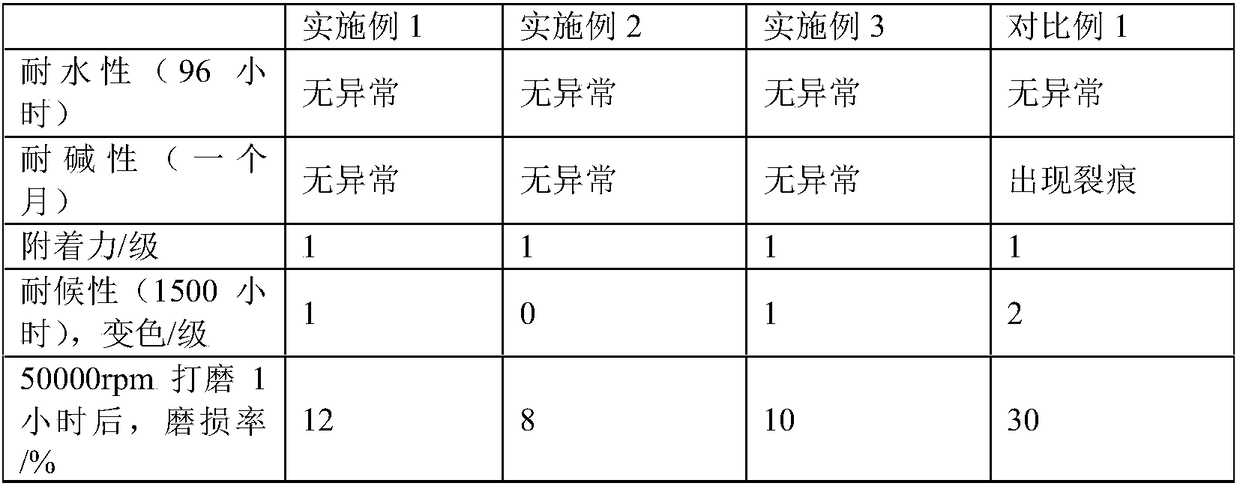

Examples

Embodiment 1

[0020] A protective paint for ship anchor chains, comprising the following components in parts by weight: 15 parts of Spartina alterniflora straw powder, 5 parts of hydroxypropyl methacrylate, 24 parts of modified furan resin, and butyl stearate 10 parts, 2 parts of aluminum foam, 4 parts of barium sulfate, 2 parts of nano zinc oxide, 25 parts of seaweed extract, 2 parts of hydroxymethyl cellulose sodium, 10 parts of polyester propylene oligomer, polytetramethylene ether 10 parts of diol, 30 parts of deionized water.

[0021] The modified furan resin is formed by mixing furan resin, maleic anhydride and graphene.

[0022] Specifically, furan resin, maleic anhydride and graphene are mixed and put into a reactor, melted, put into an extruder and extruded to obtain a modified furan resin. Wherein, the molar ratio of furan resin, maleic anhydride and graphene is 10:1:3.

[0023] The preparation method of above-mentioned ship's anchor chain protective paint, comprises the followi...

Embodiment 2

[0027] A protective paint for ship anchor chains, comprising the following components in parts by weight: 22 parts of Spartina alterniflora straw powder, 8 parts of hydroxypropyl methacrylate, 25 parts of modified furan resin, and butyl stearate 13 parts, 5 parts of aluminum foam, 8 parts of barium sulfate, 6 parts of nano-zinc oxide, 30 parts of seaweed extract, 3 parts of hydroxymethyl cellulose sodium, 12 parts of polyester propylene oligomer, polytetramethylene ether 13 parts of diol, 40 parts of deionized water.

[0028] The modified furan resin is formed by mixing furan resin, maleic anhydride and graphene.

[0029] Specifically, furan resin, maleic anhydride and graphene are mixed and put into a reactor, and after melting, they are put into an extruder and extruded to obtain a modified furan resin; the moles of the furan resin, maleic anhydride and graphene The ratio is 15:1:5 parts.

[0030] The preparation method of above-mentioned ship's anchor chain protective pai...

Embodiment 3

[0034] A protective paint for ship anchor chains, comprising the following components in parts by weight: 15-25 parts of Spartina alterniflora straw powder, 5-12 parts of hydroxypropyl methacrylate, and 24-28 parts of modified furan resin , 10-18 parts of butyl stearate, 2-8 parts of aluminum foam, 4-12 parts of barium sulfate, 2-8 parts of nano zinc oxide, 25-38 parts of seaweed extract, 2-5 parts of sodium hydroxymethyl cellulose 10-15 parts of polyester acrylate oligomer, 10-15 parts of polytetramethylene ether glycol, 30-45 parts of deionized water.

[0035] The modified furan resin is formed by mixing furan resin, maleic anhydride and graphene.

[0036] Specifically, furan resin, maleic anhydride and graphene are mixed and put into a reactor, and after melting, they are put into an extruder and extruded to obtain a modified furan resin, wherein the moles of furan resin, maleic anhydride and graphene The ratio is 18:1:6 parts.

[0037] The preparation method of above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com