NCM ternary cathode material with surface layer doping of Ce<3+> and surface layer coating of CeO2 and preparation method of the ternary cathode material

A positive electrode material and surface layer technology, applied in the field of chemical energy storage batteries, can solve the problems of capacity and structure attenuation, poor cycle stability, etc., and achieve the effects of slowing down the growth rate, low price, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Add cerium nitrate and NCM into ethanol according to the molar ratio Ce:NCM=0.01:1, and sonicate for 1 h, then mix and grind them evenly with ethanol in a mortar, calcinate at 400°C for 5 h, and cool with the furnace to obtain the final product, record for post-Ce-400.

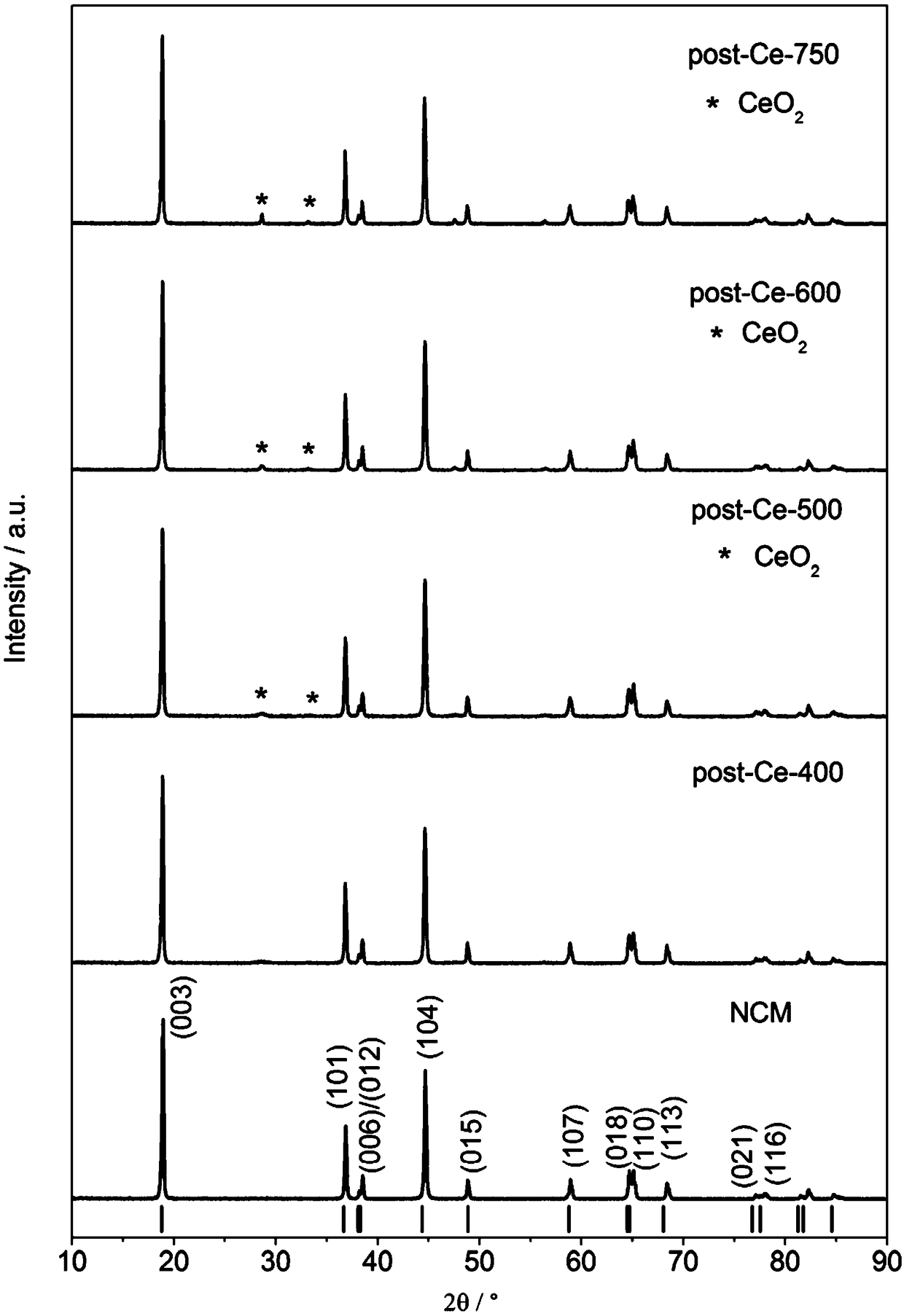

[0068] The XRD test results of post-Ce-400 are as follows figure 1 As shown, it can be seen that the position of the main peak of post-Ce-400 in this embodiment is basically the same as that of the main peak in the comparative example. In the range of 20-40 degrees, there is no miscellaneous peak phase generation, which means that there is no CeO 2 generate. According to the XRD Rietveld refinement results, in the post-Ce-400 sample, Ni 2+ The atomic percentage in the Li layer is 1.92%, indicating that Li + / Ni 2+ The shuffling problem has been improved.

[0069] The SEM test results of post-Ce-400 are as follows image 3 As shown, it can be seen that the material sample can maintain its spherical...

Embodiment 2

[0080] Add cerium nitrate and NCM into ethanol according to the molar ratio Ce:NCM=0.01:1, and sonicate for 1 hour, then mix and grind them evenly with ethanol in a mortar, calcinate at 500°C for 5 hours, and cool with the furnace to obtain the final product, namely A surface doped Ce 3+ And the surface layer is coated with CeO 2 NCM ternary cathode material, denoted as post-Ce-500.

[0081] The XRD test results of post-Ce-500 are as follows figure 1 As shown, the position of the main peak in this embodiment is basically the same as that in the comparative example, and within the range of 20-40 degrees, there is a miscellaneous peak phase CeO 2 peak generation, implying CeO on the surface of the material 2 generate. According to the XRD Rietveld refinement results, in the post-Ce-500 sample, Ni 2+ The atomic percentage in the Li layer is 1.71%, indicating that Li + / Ni 2+ The shuffling problem has been improved.

[0082] The SEM test results of post-Ce-500 are as follo...

Embodiment 3

[0094] Cerium nitrate and NCM are added into ethanol according to the molar ratio Ce:NCM=0.01:1, and ultrasonicated for 1 hour, then mixed and ground with ethanol in a mortar, calcined at 600°C for 5 hours, and cooled with the furnace to obtain the final product, namely A surface doped Ce 3+ And the surface layer is coated with CeO 2 NCM ternary cathode material, denoted as post-Ce-600.

[0095] The XRD test results of post-Ce-600 are as follows figure 1 As shown, the position of the main peak in this embodiment is basically the same as that in the comparative example, and within the range of 20-40 degrees, there is a miscellaneous peak phase CeO 2 peak generation, implying CeO on the surface of the material 2 generate. According to the XRD Rietveld refinement results, in the post-Ce-400 sample, Ni 2+ The atomic percentage in the Li layer is 1.46%, and its Li + / Ni 2+ The shuffling problem has been improved.

[0096] The SEM test results of post-Ce-600 are as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com