Preparation method of magnetic oxygen deficient cobalt ferrite bimetal oxide composite catalyst

A bimetallic oxide and composite catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. Realize recycling and improve the effect of electron transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Under vigorous stirring, add Co(NO 3 ) 2 ·3H 2 O, Fe(NO 3 ) 3 9H 2 O and citric acid.

[0032] (2) Transfer the solution obtained in step (1) to an oil bath, stir magnetically at 50-70°C for 3-5h, then place the fully stirred solution in an oven, and dry at 80-100°C for 4-7h, to obtain a xerogel.

[0033] (3) Put the above dry gel in a muffle furnace, heat up to 280-320°C at a heating rate of 10°C / min, then calcinate for 2-4h, cool to room temperature, take it out, and grind to obtain black CoFe 2 o 4 (CFO) powder.

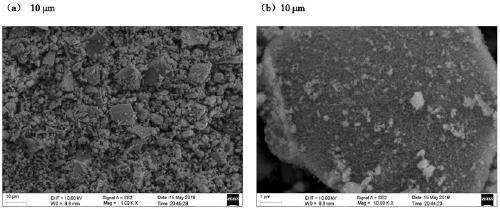

[0034] (4) the black CoFe prepared by step (3) 2 o 4 The powder is placed in a tube furnace and calcined at 280-320°C for 3h in a hydrogen atmosphere with a flow rate of 0.08-0.12mL / min to obtain the following: figure 1 The magnetic oxygen-deficient cobalt ferrite double metal oxide composite catalyst shown.

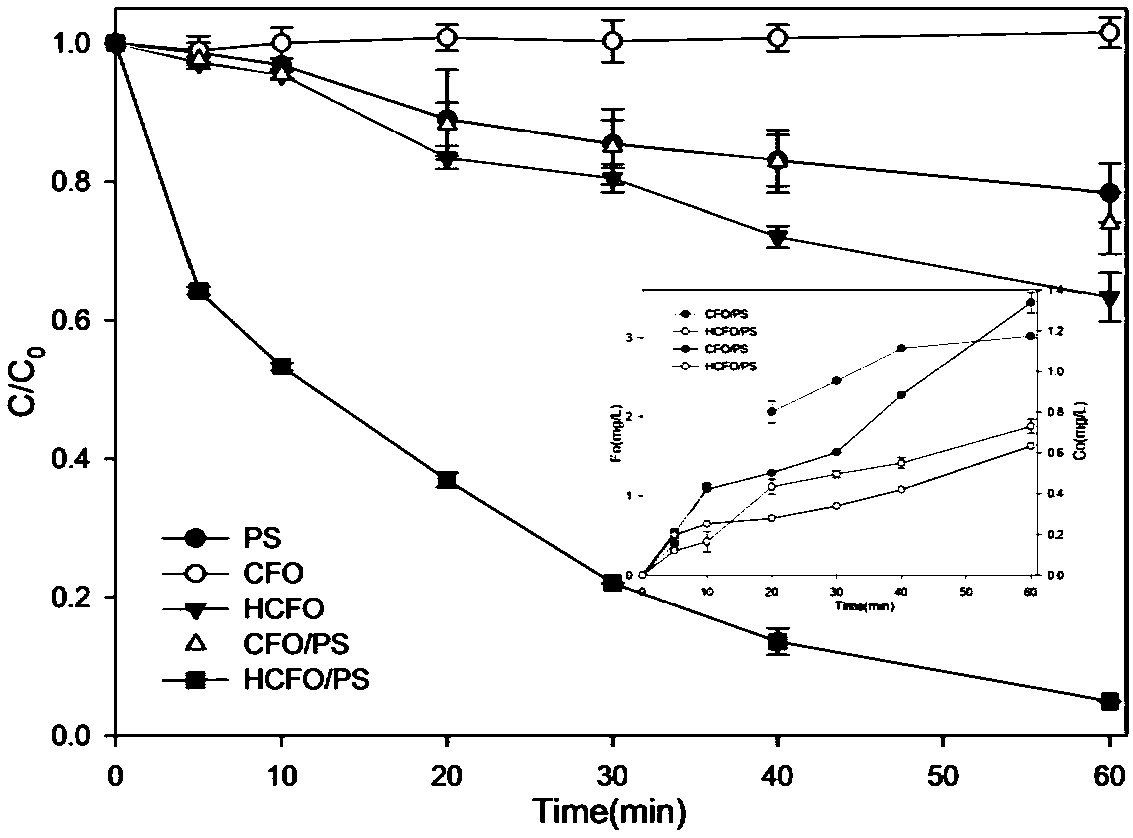

[0035] Add 100 mL of bisphenol A solution containing 30 mg / L to the reactor, then add sodium persulfate and the magnetic oxygen-defic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com