A high-performance photocatalytic nitrogen fixation g-c that can be produced industrially 3 no 4 /Oxide composite material preparation method

A composite material, g-c3n4 technology, applied in the field of photocatalytic materials and its preparation, can solve the problems of lack of scalability, low specific surface area, high production route cost, etc., achieve excellent photocatalytic nitrogen fixation performance, low preparation cost, The effect of high nitrogen fixation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

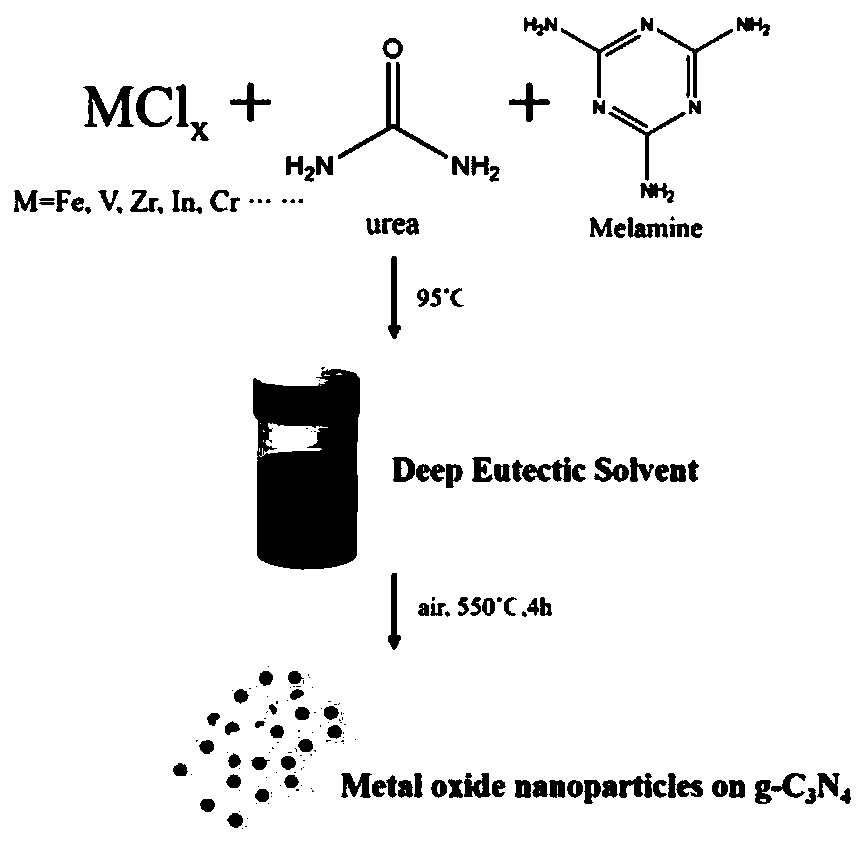

[0031] The melamine of 0.01mol ferric chloride, 0.12mol urea and 0.7985g is formed deep eutectic solvent in 95 ℃ of oil baths, then the deep deep eutectic solvent that forms is roasted in muffle furnace, and roasting condition is 5℃·min -1 The heating rate was raised to 550°C, and after 4 hours of heat preservation, it was cooled with the furnace to obtain the finished product.

Embodiment 2

[0033] The melamine of 0.01mol vanadium trichloride, 0.12mol urea and 1.0913g is formed deep deep eutectic solvent in 95 ℃ of oil baths, then the deep deep eutectic solvent that forms is roasted in muffle furnace, and roasting condition is 5℃·min -1 The heating rate was raised to 550°C, and after 4 hours of heat preservation, it was cooled with the furnace to obtain the finished product.

Embodiment 3

[0035] The melamine of 0.01mol indium chloride, 0.12mol urea and 1.1105g is formed deep deep eutectic solvent in 95 ℃ of oil baths, then the deep deep eutectic solvent that forms is roasted in muffle furnace, and roasting condition is with 5 ℃·min -1 The heating rate was raised to 550°C, and after 4 hours of heat preservation, it was cooled with the furnace to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com